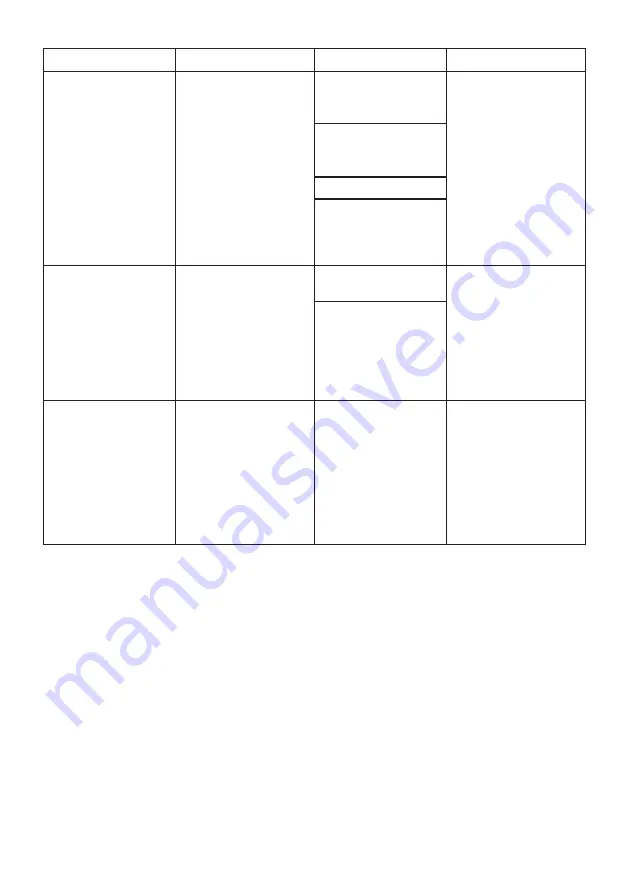

31

Following release,

the star grip

doesn’t return to

the central position

Casing damaged or

star grip operation

not working

smoothly?

Damage to the

torsion spring for

reset

Repair by an

authorized dealer,

by personnel

specially trained

by LUKAS, or by

LUKAS itself

Soiled valve or star

grip

Defective valve

Other mechanical

damage (e.g. star

grip)

Hydraulic fluid

leaking from the

piston rod

Defective rod seal

Repair by an

authorized dealer,

by personnel

specially trained

by LUKAS, or by

LUKAS itself

Damage to the

piston

The useful

operating time

between the

individual charging

cycles is less than

5 minutes, despite

charging the

batteries according

to the instructions.

Battery defective

Replace battery

Fault

Check

Cause

Solution