17

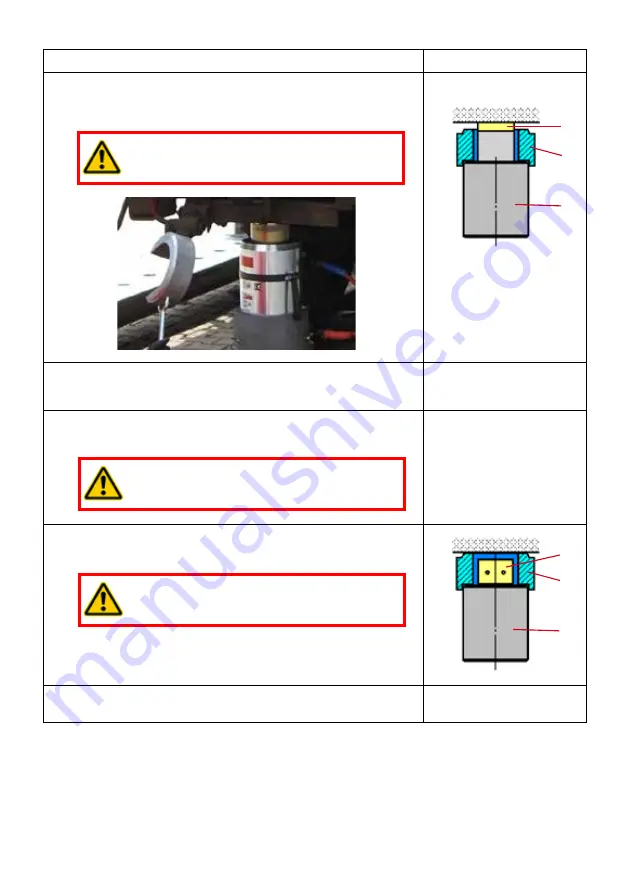

2. Place the first cylinder attachment “C” centrally on the

cylinder body using the fork lever.

Operation

Schematic

WARNING / CAUTION

underneath the load!

B

A

C

3. Lower the load onto this cylinder attachment and retract

the piston.

4. Remove the standard piston guard plate from the cylinder

if present.

5. Insert first piston attachment "D" with neck in piston

centring device (use fork lever!).

WARNING / CAUTION

underneath the load!

WARNING / CAUTION

underneath the load!

D

A

C

6. Completely extend load again by means of piston.

Summary of Contents for HP 25/ T700R

Page 2: ...2...