12

10

Dismantling of the device / Stop after operation

10.1 Cutter unit

After operation, close the blades to a tip distance of a few mm. This relaxes the unit

hydraulically and mechanically.

10.2 Hydraulic power pack

Stop the hydraulic power pack after operation.

10.3 Hoses

Uncouple the red hose first and the blue hose second as described under 8.3. Put dust

caps over the couplings.

10.4 Electric lines

During longer breaks, the electric lines should be disconnected.

11

Maintenance

11.1 Cutter unit

After each operartion and after the end of the shift respectively, a sight check must be

carried out, at least once a year. A function test must be accomplished every 500

operating hours or if there are doubts about the safety or reliability (clean first if dirty).

Visual inspection

Cutter blades

• Cutting edges free from spalling and deformation.

• Distance of blades < 3 mm.

• Cutting surfaces slide past each other without contact.

• Blades free from cracks.

Cutter unit

• Distance between blade tips > 125 mm.

• No leakages.

• Handle existing and fast.

Hoses

• Check according safety instructions for hoses (see item 5).

• Check for oil leakage.

Function testing

• Perfect opening and closing with external / internal switch actuation

• Check of central bolt tightening torque

MA = 130

+10

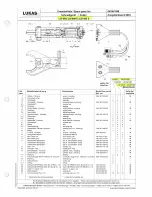

NM (see also drawing to Section 12.3.1).

11.2 Covers

• Inspection of safety devices at / around cutter unit.

Summary of Contents for LSI 400

Page 24: ...3 c xI z1 1 9 I _ I...

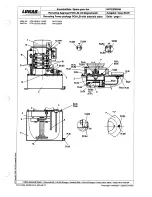

Page 25: ...Opening Hydraulic cylinder Culling...

Page 26: ...Hydraulic diagram T A...