13

right

false

9

Cutting

9.1 Safety instructions

-

Woldwide all national safety guidelines must be observed and complied.

-

If there is a explosion risk, do not use motor pumps because of sparks. In such

cases, manual pumps must be used.

When working with the cutter, you must wear:

-

work or protective clothing,

-

Helmet with visor or goggles,

-

Gloves

Before using the cutter, ensure that the movement of the blades does not represent a

danger to persons or objects as a result of blade movement or catapulted cut materials.

It is strictly forbidden to grip between the blades!

The following must not be cut:

-

energised cables

-

Lines with pressurised gas or fluid

-

Pre-stressed and hardened components (such as springs, spring steel,

steering columns, rollers)

-

Composite materials (steel/concrete)

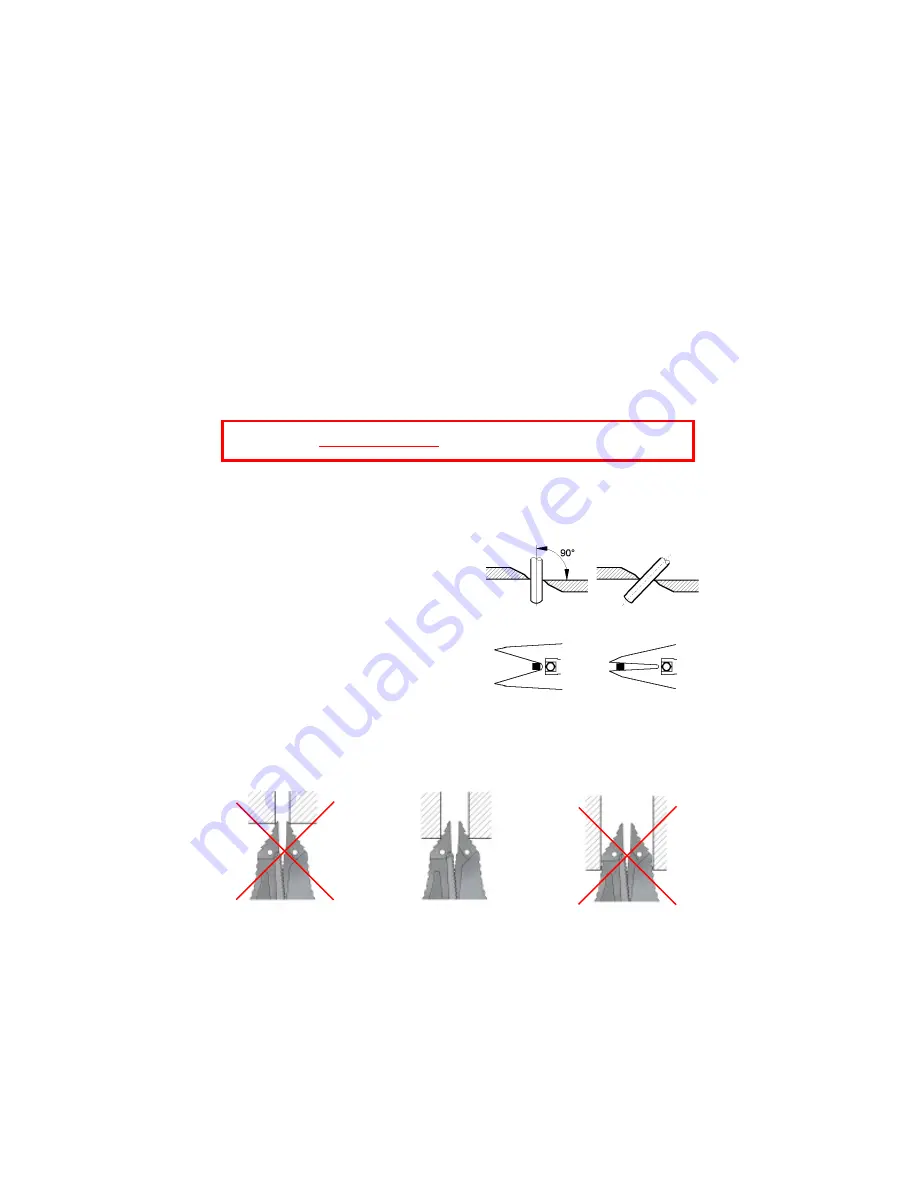

9.2 Cutting procedure

The blades must be applied at right angles

to the object to be cut. Higher cutting

performance is achieved if the cutting is

as close as possible to the blade fulcrum.

When cutting, the gap between the blade

tips must not exceed 3 mm (Risk of blade

fracture).

9.2.1

Attention!

When cutting with curved blades, on the blade tips the full cutting performance must

not be utilized. Cutting in profiles up to 2 mm thickness is permitted.

9.3 Spreading procedure (only LSI 55)

Use front region of the tips only for enlaging a gap.

Tips grip securely

Use tips only, do not

damage the arms

Grip area to small, tips

may break away