8

cutting

open

5.5 Periods for checking and replacing hose lines

-

Check the hose lines for external damage, tears, bends and inflating after

every use

.

-

The operator must ensure that hose lines are replaced at reasonable intervals,

even if no safety deficiencies can be detected on the hose.

-

The hose line must be replaced 10 years after manufacture at the latest (see

label)!

-

Hose lines must be

checked before first start-up

of the technical equipment

and then

at least once a year to

ensure a safe

working condition by a properly

trained person

. For examples of possible deficiencies, see 5.6 below.

5.6 Examples of possible deficiencies to hose lines

-

Damage to the external layer to the insert (e.g. chafing, cuts or tears).

-

External layer becoming brittle (tears to the hose material).

-

Deformations not corresponding to the natural shape of the hose when under

pressure or depressurised, or when bent, e.g. separation of layers, bubbles,

squashed areas, bends.

-

Leaks.

-

Installation requirements not observed.

-

Hose leaves the fittings.

-

Damage or deformation to the fittings which alleviates the function and stability of

the fittings or the hose – fittings connection.

-

Corroded fittings or metal inserts, which alleviates the stability.

-

Storage times and period of use exceeded.

6

Functions and performance

6.1 Description

The device is designed such that a hydraulic piston is connected across two equal,

opposing, symmetrical blades via mechanical joints and so cuts materials. The

blades are designed for the application in terms of their geometry so that sliding of

the material being cut is avoided as much as possible.

6.2 Controlling the working movements

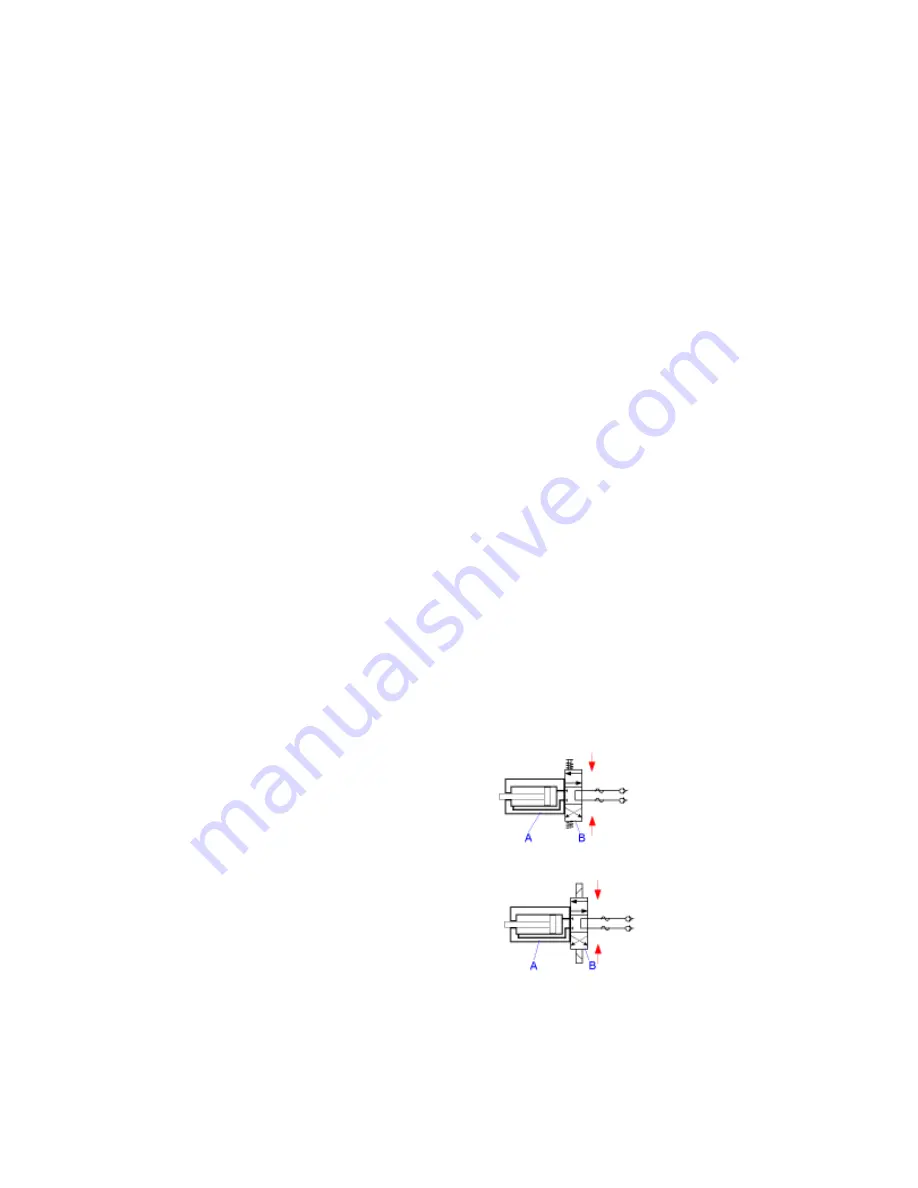

6.2.1 LSI cutter with 4/3-way valve

The movement of the blades is controlled by the star grip on the fitted valve (see first page

pos. 1).

The circuit diagram is simplified here to make

the function comprehensible

(hydraulic cylinder (A) + 4/3-way valve (B).

6.2.2 LSI cutter with electrical controls

The movement of the blades is controlled by the electric control unit on the fitted

valve (see first page pos. 2).

The circuit diagram is simplified here to make

the function comprehensible

(hydraulic cylinder (A) + 4/3-way valve (B).

cutting

open