1.5

Model 644E-42/944E-42

Rev. 6/04

Safety Practices

1.6

SAFETY INSTRUCTIONS

Following are general safety statements to consider

before performing maintenance procedures on a vehicle.

Additional statements related to specific tasks and

procedures are located throughout this manual and are

listed prior to any work instructions to provide safety

information before the hazard occurs.

For all safety messages, carefully read, understand and

follow the instructions before proceeding.

1.6.1

Personal Hazards

HAIR and CLOTHING: DO NOT wear loose clothing or

jewelry. Tie up or restrain hair. Wear the correct safety

equipment for the job (including but not limited to: hard

hat, safety shoes, safety glasses, goggles, face shield,

heavy gloves, hearing protection, reflective clothing, wet-

weather gear, respirator or filter mask).

EYE PROTECTION: Always wear appropriate eye

protection when chiseling, grinding, sanding, welding,

painting, repairing hydraulic systems, checking, testing or

charging the battery.

BREATHING PROTECTION: Wear respiratory

protection when grinding or painting.

HEARING PROTECTION: Always wear hearing

protection in a high-noise area.

FOOT PROTECTION: Wear protective footwear with

reinforced toe caps and slip-resistant soles.

LIFTING: NEVER lift a heavy object without the help of at

least one assistant or a suitable sling and hoist.

1.6.2

Equipment Hazards

OWNERS/OPERATORS MANUAL: Before operating the

vehicle, carefully read, understand and follow the

Owners/Operators Manual.

OPERATIONAL PROTECTION: Before operating the

vehicle or returning it for operational use, check that the

operator’s protective structure is intact, undamaged,

unmodified and secure.

LIFTING OF EQUIPMENT: Before using any lifting

equipment (chains, slings, brackets, hooks, etc.), verify

that it is of the proper capacity, in good working condition

and properly attached.

NEVER stand or otherwise become positioned under a

suspended load or under raised equipment. The load or

equipment could fall or tip.

DO NOT use a hoist or jack to support raised equipment.

A hoist or jack failure can allow the equipment to fall or tip.

Always support equipment with proper capacity blocks or

stands that are properly rated for the load.

COMPRESSED AIR: Before and during the use of

compressed air, wear eye protection and advise other

personnel in the work area that compressed air is about

to be used.

HAND TOOLS: Always use the proper tool for the job;

keep tools clean and in good working order, and use

special service tools only as recommended.

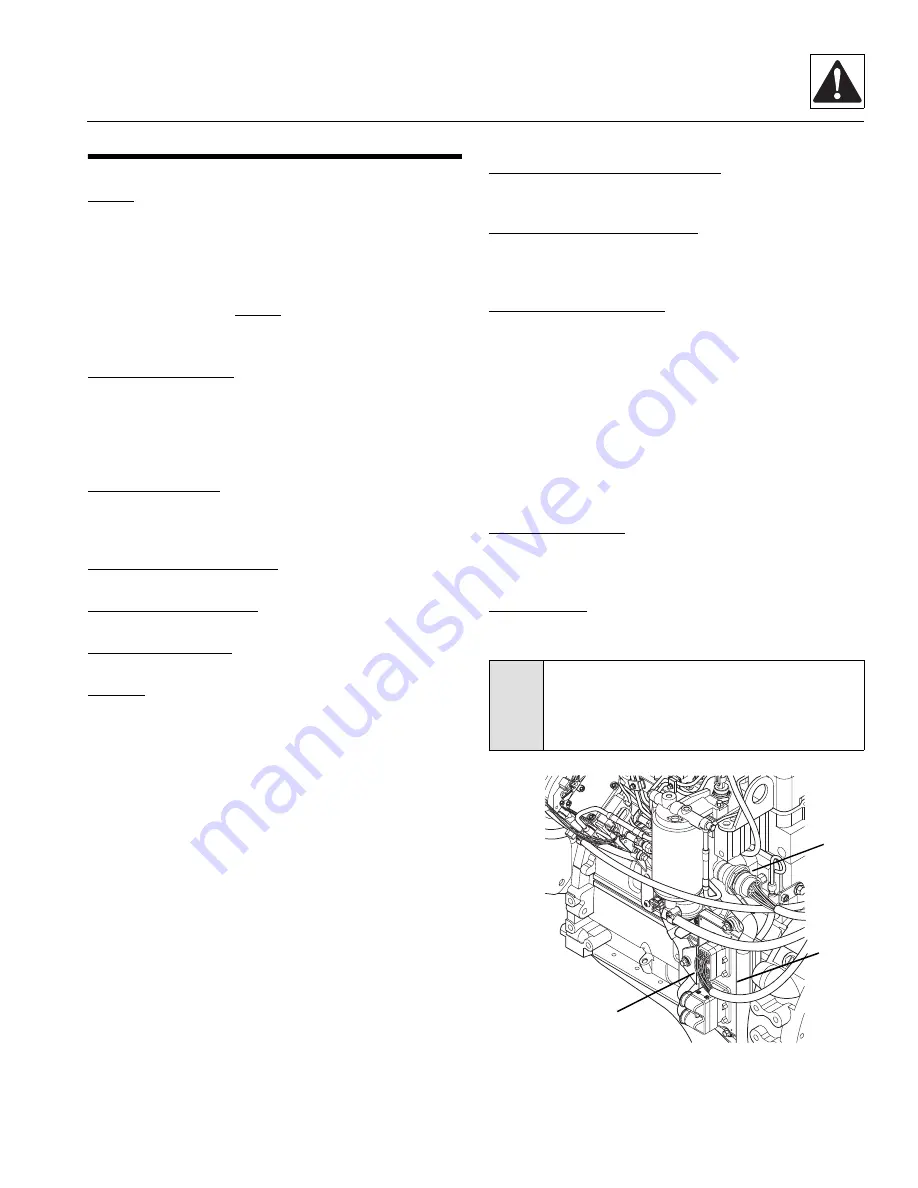

CAUTION:

(944E-42 Only) When doing

welding anywhere on the vehicle disconnect

the wire harness (1 and 2) from the Engine

Control Module (ECM) (3) on the engine.

MU5510

944E-42 Only

1

2

3

Summary of Contents for 944E-42

Page 1: ......

Page 2: ......

Page 14: ...Safety Practices 1 8 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 102: ...Boom 3 56 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 139: ...4 37 Model 644E 42 944E 42 Rev 6 04 Cab and Covers This Page Intentionally Left Blank...

Page 144: ...Cab and Covers 4 42 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 265: ...8 15 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 269: ...8 19 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 273: ...8 23 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 277: ...8 27 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 281: ...8 31 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 285: ...8 35 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 289: ...8 39 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 293: ...8 43 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 297: ...8 47 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 301: ...8 51 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 407: ...8 157 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 425: ...8 175 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 501: ...8 251 Model 644E 42 944E 42 Rev 6 04 Hydraulic System MT1950 2 3 4 5 6 7 8 5 5...

Page 507: ...8 257 Model 644E 42 944E 42 Rev 6 04 Hydraulic System MT1950 1 2 3 4 5 6 7 4 4...

Page 508: ...Hydraulic System 8 258 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 525: ...9 17 Model 644E 42 944E 42 Rev 6 04 Electrical System This Page Intentionally Left Blank...

Page 554: ...Electrical System 9 46 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 759: ...10 3 Model 644E 42 944E 42 Rev 6 04 Stabil TRAK System This Page Intentionally Left Blank...

Page 765: ...10 9 Model 644E 42 944E 42 Rev 6 04 Stabil TRAK System This Page Intentionally Left Blank...

Page 785: ...10 29 Model 644E 42 944E 42 Rev 6 04 Stabil TRAK System This Page Intentionally Left Blank...

Page 800: ...Stabil TRAK System 10 44 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 832: ...Transfer Carriage 11 32 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 840: ...12 8 Model 644E 42 944E 42 Rev 6 04 Index...

Page 841: ...Accident Prevention Tags OS2180 8990403 Origin 5 00 Accident Prevention Tags...

Page 842: ...Accident Prevention Tags OS2180 8990403 Origin 5 00...

Page 843: ......

Page 844: ......