8.231

Model 644E-42/944E-42

Rev. 6/04

Hydraulic System

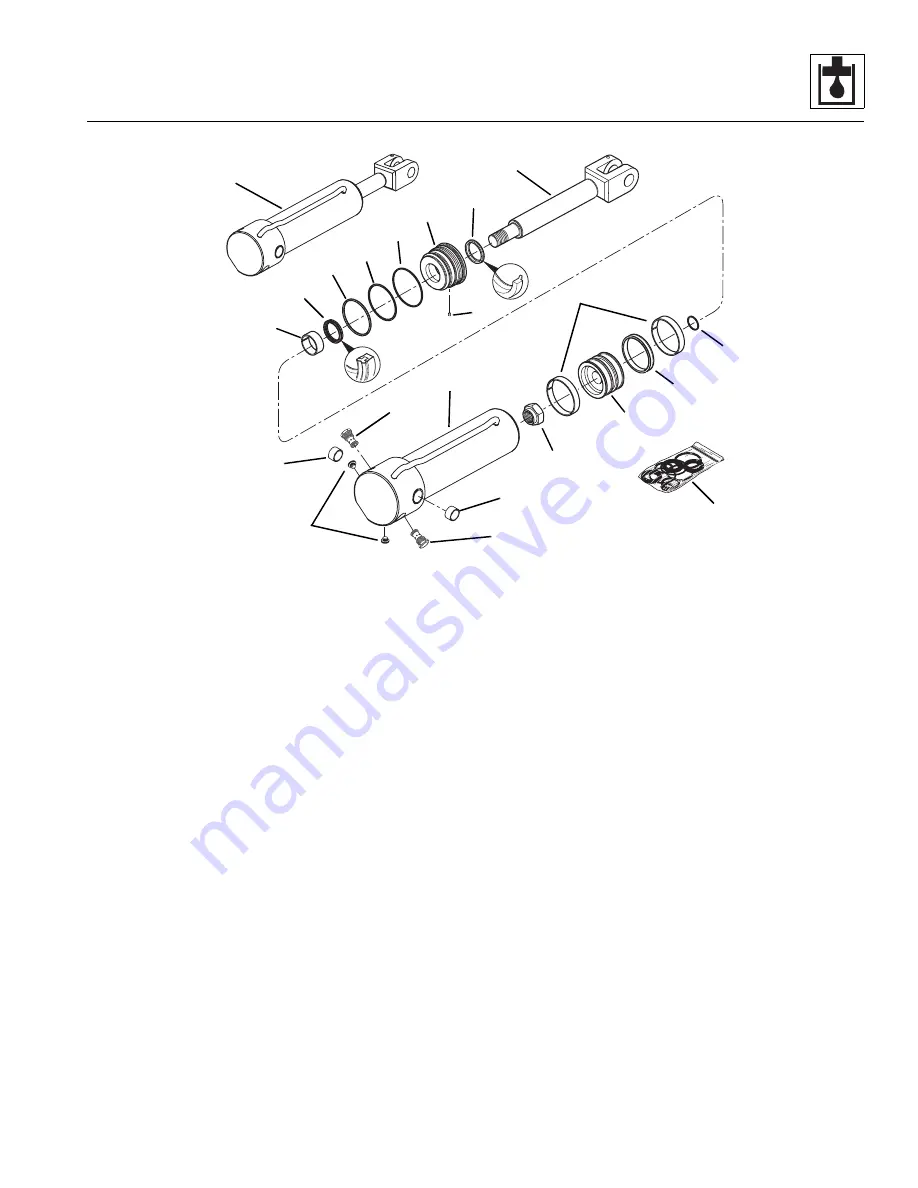

IMPORTANT: Protect the finish on the rod at all times.

Damage to the rod can cause premature seal failure.

4. Use a pin spanner wrench to unthread the head

gland (4) from the tube (5). The head gland is

installed at a torque of 300-400 lb-ft (407-542 Nm),

so a considerable amount of force is required to

remove it. Carefully slide the head gland down along

the rod toward the eyelet end, away from the cylinder

tube.

5. Remove the locking insert (6) from its hole in the

head gland threads. Pry or drill out the insert as

required. DO NOT damage the head gland threads.

A new locking insert will be required for reassembly.

IMPORTANT: When sliding the rod and piston assembly

in the tube, DO NOT damage the piston by scraping it

against the threads in the tube. Keep the rod in line with

the tube to prevent binding.

6. Carefully withdraw the rod (7) straight out of the

tube (5). Keep the rod straight during withdrawal to

help avoid scratching, nicking or damaging the

tube (5).

7. Secure the rod eyelet and remove the locknut (8)

from the threaded end of the rod. Discard the nut; a

new nut will be required for reassembly.

Note: Heating the nut (8) to approximately 300° F

(150° C) may also be required to break the seal formed

by the Loctite Threadlocker #271 (red) applied to the nut

when installed. The application of significant force is

required to overcome the 1840-2025 lb-ft

(2495-2745 Nm) of torque to the nut.

8. Remove the piston (9) from the rod (7).

9. Remove the small o-ring (10) from the piston.

10. Remove the head gland (4) from the rod (7).

11. Remove both precision wearbands (11) from the

piston (9).

12. Remove the capped T-seal (12) from the piston (9).

Note: The T-seal actually consists of four components; a

wide, flexible inner band, the flexible T-seal band itself,

and two supportive split caps that mount on either side of

the “T” seal band.

13. Remove the o-ring (13), the back-up ring (14) and

the o-ring (15) from the head gland (4).

14. Remove the heavy-duty rod wiper (16) from the head

gland (4).

15. Remove the precision wearband (17) and deep

Z-seal with rod back-up (18) from inside the head

gland (4).

16. Inspect and remove the two polylube bearings (19).

17. Remove the two plugs (20) from the base end of the

tube.

MU3710

2

3

4

5

6

7

8

9

10

11

13

14

15

16

17

18

19

20

21

12

Summary of Contents for 944E-42

Page 1: ......

Page 2: ......

Page 14: ...Safety Practices 1 8 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 102: ...Boom 3 56 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 139: ...4 37 Model 644E 42 944E 42 Rev 6 04 Cab and Covers This Page Intentionally Left Blank...

Page 144: ...Cab and Covers 4 42 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 265: ...8 15 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 269: ...8 19 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 273: ...8 23 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 277: ...8 27 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 281: ...8 31 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 285: ...8 35 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 289: ...8 39 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 293: ...8 43 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 297: ...8 47 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 301: ...8 51 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 407: ...8 157 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 425: ...8 175 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 501: ...8 251 Model 644E 42 944E 42 Rev 6 04 Hydraulic System MT1950 2 3 4 5 6 7 8 5 5...

Page 507: ...8 257 Model 644E 42 944E 42 Rev 6 04 Hydraulic System MT1950 1 2 3 4 5 6 7 4 4...

Page 508: ...Hydraulic System 8 258 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 525: ...9 17 Model 644E 42 944E 42 Rev 6 04 Electrical System This Page Intentionally Left Blank...

Page 554: ...Electrical System 9 46 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 759: ...10 3 Model 644E 42 944E 42 Rev 6 04 Stabil TRAK System This Page Intentionally Left Blank...

Page 765: ...10 9 Model 644E 42 944E 42 Rev 6 04 Stabil TRAK System This Page Intentionally Left Blank...

Page 785: ...10 29 Model 644E 42 944E 42 Rev 6 04 Stabil TRAK System This Page Intentionally Left Blank...

Page 800: ...Stabil TRAK System 10 44 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 832: ...Transfer Carriage 11 32 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 840: ...12 8 Model 644E 42 944E 42 Rev 6 04 Index...

Page 841: ...Accident Prevention Tags OS2180 8990403 Origin 5 00 Accident Prevention Tags...

Page 842: ...Accident Prevention Tags OS2180 8990403 Origin 5 00...

Page 843: ......

Page 844: ......