9.187

Model 644E-42/944E-42

Rev. 6/04

Electrical System

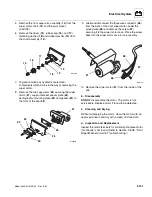

4. Disconnect the bottom of the return spring (16) from

the bolt (17) at the bottom of the mounting

bracket (18) inside the cab.

5. Remove the clevis locking pin (19) from the clevis on

the linkage assembly (20).

6. Remove the two slotted pan head screws (21), flat

washers (22) and nuts (23) securing the sensor and

linkage assembly to the mounting bracket.

7. Slide the sensor (15) and linkage assembly (20) out

of the slot (24) on the mounting plate (18).

8. Remove the snap ring (25) and flat washer (26)

securing the sensor (27) to the linkage

assembly (28).

c. Disassembly

DO NOT disassemble the sensor. The sensor is not

serviceable. Replace the sensor if found to be defective.

d. Cleaning and Drying

Without submerging the sensor, clean the sensor with an

approved solvent and dry with a clean, lint-free cloth.

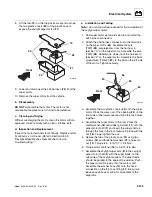

e. Installation and Testing

1. Slide the sensor (27) onto the linkage assembly

shaft (28).

2. Lock in place on shaft using a flat washer (26) and

snap ring (25).

3. Slide the sensor (15) and linkage assembly (20) into

the slot (24) on the mounting plate (18).

4. Line up the hole in the clevis on the linkage

assembly (20) with the hole on the throttle pedal stop

plate (25).

5. Secure clevis with the clevis locking pin (19).

6. Secure the sensor to the cab mounting bracket (18)

with two slotted pan head screws (21), flat washers

(22) and nuts (23). Torque nuts to 2-4 lb-ft

(1.5-3 Nm).

7. Connect the ECM cab harness connector (14) to the

sensor (15).

8. If the vehicle has dual batteries, connect both

negative battery cables (8 and 9) to both batteries.

Connect the lower negative battery cable (8) to the

negative (-) terminal on the lower battery (10). Swing

the upper battery box (13) in and make sure that the

lip (12) on the upper battery box slides below the

knob (11). Secure in place with the knob.

9. Lower and lock engine cover. To release and lower

the engine cover (6) from the fully raised position, lift

up slightly on the cover and push the upper part of

the right gas shock (7) (orange tab) to the left. Line

up the upper part of the shock lock tube with the

lower part of the gas shock and pull the cover down

to the closed position.

10. Start the engine. Engine rpm should increase as

soon as the throttle pedal is depressed and continue

to increase until the throttle pedal is fully depressed.

If there is free play in the pedal stroke, refer to

Section 4.3.6, “Throttle Pedal Replacement,” for

adjustment procedure.

15

16

17

18

19

20

21

22

23

24

25

MU5740

14

MU5760

25

26

27

28

Summary of Contents for 944E-42

Page 1: ......

Page 2: ......

Page 14: ...Safety Practices 1 8 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 102: ...Boom 3 56 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 139: ...4 37 Model 644E 42 944E 42 Rev 6 04 Cab and Covers This Page Intentionally Left Blank...

Page 144: ...Cab and Covers 4 42 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 265: ...8 15 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 269: ...8 19 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 273: ...8 23 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 277: ...8 27 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 281: ...8 31 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 285: ...8 35 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 289: ...8 39 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 293: ...8 43 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 297: ...8 47 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 301: ...8 51 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 407: ...8 157 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 425: ...8 175 Model 644E 42 944E 42 Rev 6 04 Hydraulic System This Page Intentionally Left Blank...

Page 501: ...8 251 Model 644E 42 944E 42 Rev 6 04 Hydraulic System MT1950 2 3 4 5 6 7 8 5 5...

Page 507: ...8 257 Model 644E 42 944E 42 Rev 6 04 Hydraulic System MT1950 1 2 3 4 5 6 7 4 4...

Page 508: ...Hydraulic System 8 258 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 525: ...9 17 Model 644E 42 944E 42 Rev 6 04 Electrical System This Page Intentionally Left Blank...

Page 554: ...Electrical System 9 46 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 759: ...10 3 Model 644E 42 944E 42 Rev 6 04 Stabil TRAK System This Page Intentionally Left Blank...

Page 765: ...10 9 Model 644E 42 944E 42 Rev 6 04 Stabil TRAK System This Page Intentionally Left Blank...

Page 785: ...10 29 Model 644E 42 944E 42 Rev 6 04 Stabil TRAK System This Page Intentionally Left Blank...

Page 800: ...Stabil TRAK System 10 44 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 832: ...Transfer Carriage 11 32 Model 644E 42 944E 42 Rev 6 04 This Page Intentionally Left Blank...

Page 840: ...12 8 Model 644E 42 944E 42 Rev 6 04 Index...

Page 841: ...Accident Prevention Tags OS2180 8990403 Origin 5 00 Accident Prevention Tags...

Page 842: ...Accident Prevention Tags OS2180 8990403 Origin 5 00...

Page 843: ......

Page 844: ......