35

P

P

o

o

s

s

s

s

i

i

b

b

l

l

e

e

p

p

r

r

o

o

b

b

l

l

e

e

m

m

s

s

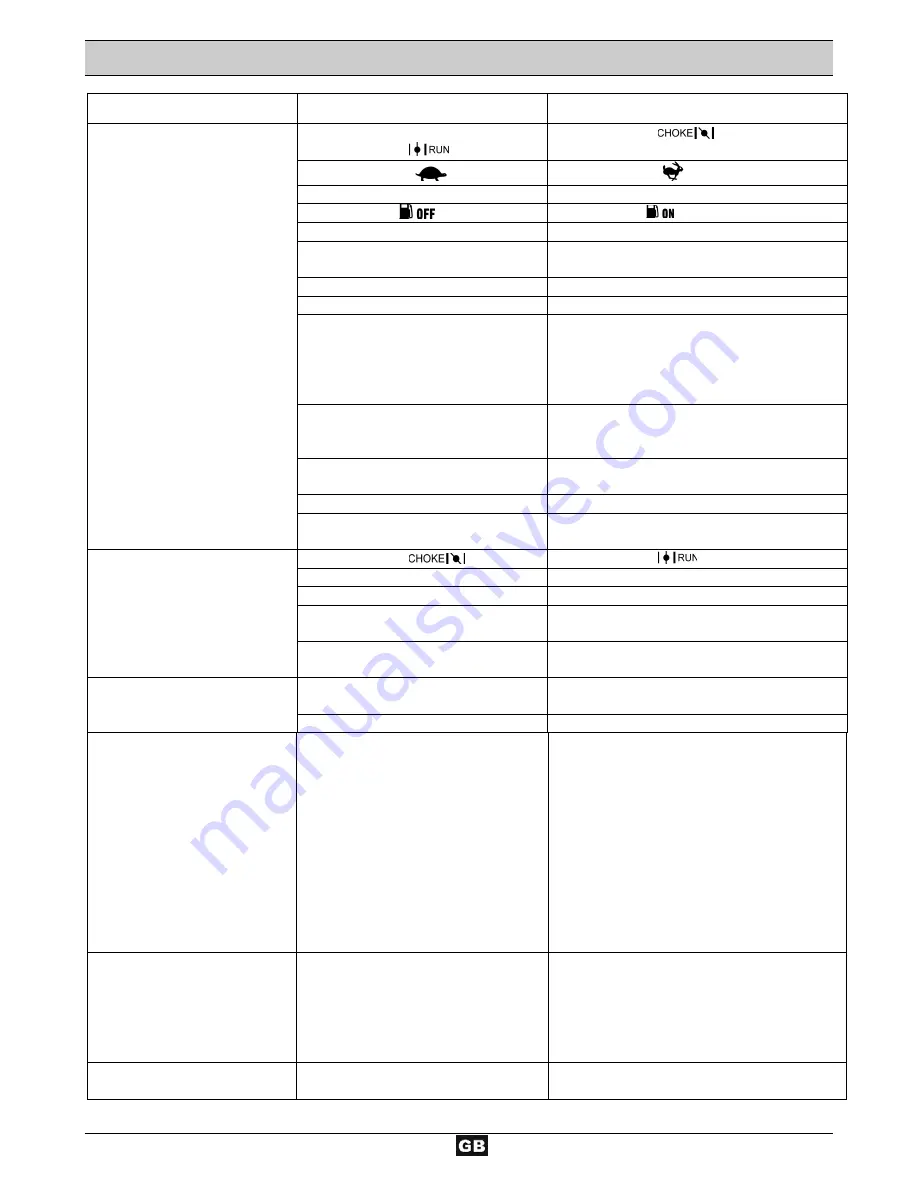

Fault

Possible cause

Remedy

Engine cold.

Choke lever put to

.

Put choke lever to

.

Throttle lever put to

.

Put throttle lever to

.

Ignition switch put to OFF.

Put ignition switch to ON.

Fuel valve put to

.

Put fuel valve to

.

No fuel supply

Check the fuel quantity

Fuel old or contaminated.

Drain the fuel into a container outdoors.

Fill the

tank with fresh and clean fuel.

Fault in the fuel line

Check the fuel line for kinks or damages

Spark plug connector not placed on.

Place on the spark plug connector.

No ignition spark.

a) Clean or replace the spark plug.

b) Check the ignition cable.

c) Fault cannot be eliminated?

Get the manufacturer or authorised service staff

to check the ignition system.

Engine flooded.

Screw off, clean and dry the spark plug. Then pull

the cranking rope several times and reinstall the

spark plug.

Carburettor defective

Contact the manufacturer or the responsible

customer service respectively.

Engine defective.

Replace the engine.

Engine does not start.

Internal fault.

Contact the manufacturer or the responsible

customer service respectively.

Choke lever put to

.

Put choke lever to

.

Spark plug connector not firmly placed on. Firmly place on the spark plug connector.

Vent in the tank cap blocked.

Clean the tank cap and the vent.

Fuel old or contaminated.

Drain the fuel into a container outdoors.

Fill the

tank with fresh and clean fuel.

Engine is sputtering.

(runs erratically)

Incorrect carburetor adjustment.

Have the caburetor adjusted correctly. (customer

service)

Machine overloaded.

a) Reduce material feeding.

b) Do not exceed the max. branch diameter.

Decreasing engine power.

Machine is blocked.

Thoroughly clean inside the machine.

Logs are not being split properly

(insufficient splitting performance).

⇒

The log is not positioned correctly.

⇒

The log exceeds the maximum

dimensions or the wood is too hard for

the performance of the machine.

⇒

Splitting blade does not split log.

⇒

Hydraulic pressure too low.

⇒

Release rods bent (hydraulic tappet not

quite pressed in).

⇒

Reposition the log correctly.

⇒

Cut the log to the required dimensions.

⇒

Sharpen splitting blade, check for burrs or

notches.

⇒

Check the oil level and add more oil if

necessary.

If the problem cannot be rectified, refer to the

manufacturer or other approved service centre.

⇒

Arrange for manufacturer or authorised

company to adjust the rods.

Splitting column moves unsteadily

or with strong vibrations.

⇒

Air in the circuit.

⇒

Splitting column not sufficiently

lubricated or oiled.

⇒

Check the oil level and add more oil if

necessary.

⇒

Lubricate splitting column or oil with

environmentally friendly spray oil.

If the problem cannot be rectified, refer to the

manufacturer or other approved service centre.

Splitting column does not move in.

⇒

Hydraulic pump defective.

⇒

To correct the problem, refer to the

manufacturer or other approved service centre.