TC180 09

Maintenance and Service

Be aware

that the machine should always

have the on/off switch (

16

) set to the off

position and be unplugged from any outlet

before any inspection, adjustments,

maintenance or cleaning is performed.

–

Before each use

inspect the general

condition of the machine. Check for loose

screws, misalignment or binding of moving

parts, cracked or broken parts, damaged

electrical wiring and any other condition that

may affect its safe operation. If abnormal noise

or vibration occurs, have the problem

corrected before further use.

–

Each day

remove all debris from the table

with a soft brush, cloth or vacuum. Also

lubricate all moving parts with premium

lightweight machine oil.

Do not use

solvents or caustic agents to clean the

power tool.

Changing the disc

– Remove the plug form the outlet socket.

– Unscrew the three screws (

30

) and then

remove the safety hood (

8

).

– Place the wrench (

31

) on the motor shaft,

and then using wrench (

34

) loosen the flange

nut in the direction of the rotation of the disc.

Caution left handed thread

– Remove the outer flange (

35

) and disc (

2

).

– Clean the mounting flange, and outer flange.

And then place a new disc on to the mounting

blade, making sure that the disc spins in the

correct direction.

– Replace the outer flange, and then tighten up

going the opposite direction to the direction of

the blade spin.

– Re mount the safety hood (

8

) using the three

screws (

30

).

Summary of Contents for TC180

Page 1: ...SAFETY AND OPERATING MANUAL WATER COOLED TILE CUTTER TC180 ORIGINAL INSTRUCTIONS TC180...

Page 14: ...TC180 12...

Page 15: ...TC180 13 PARTS LIST...

Page 16: ...TC180 14 PARTS LIST...

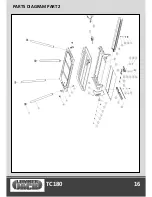

Page 17: ...TC180 15 PARTS DIAGRAM PART 1...

Page 18: ...TC180 16 PARTS DIAGRAM PART 2...

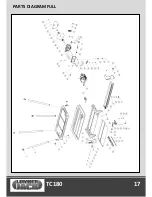

Page 19: ...TC180 17 PARTS DIAGRAM FULL...