TC180 06

ASSEMBLY

Avoid unintentional starting of the

machine. During assembly and for all

work on the machine, the power plug

must not be connected to the mains

supply.

Carefully remove all parts included in the

delivery from their packaging.

Remove all packaging material from the

machine and the accessories provided.

Before starting the operation of the machine

for the first time, check if all parts listed in the

box content section have been supplied.

Note:

Check the power tool for possible

damage. Before further use the machine,

check that all protective devices are fully

function. Any lightly damaged parts must be

carefully checked to ensure flawless operation

of the tool. All parts must be properly

mounted and all conditions fulfilled that

ensure faultless operation.

Damaged protective devices and parts must be

immediately replaced by an authorised service

centre.

– Insert the legs into the base of the trough

(

3

). And then stand it on its legs.

– Lower the main body of the tool into the

trough (

3

).

– Place cooling water pump (

13

) in to the trough

(

3

).

– Fill the trough (

3

) with water until the pump

inlet is covered by 10mm.

Summary of Contents for TC180

Page 1: ...SAFETY AND OPERATING MANUAL WATER COOLED TILE CUTTER TC180 ORIGINAL INSTRUCTIONS TC180...

Page 14: ...TC180 12...

Page 15: ...TC180 13 PARTS LIST...

Page 16: ...TC180 14 PARTS LIST...

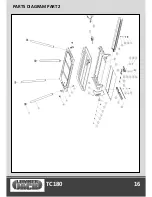

Page 17: ...TC180 15 PARTS DIAGRAM PART 1...

Page 18: ...TC180 16 PARTS DIAGRAM PART 2...

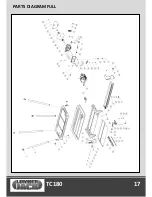

Page 19: ...TC180 17 PARTS DIAGRAM FULL...