Before using the power tool, be

aware of the following;

– The power tool must be set up so that it

stands in a stable position.

– Make sure all covers are removed and all

safety device attached correctly, before the

machine is started.

–The cutting wheel rotates freely.

– Unscrew transport screw (

11

) so that the

machine head (

29

) moves freely along the

track.

On/Off Switch

– Press “I” in the On/Off switch (

16

) to start he

disc spinning.

– Wait until the disc is spinning at its maximum

speed and the pump has started to supply

water to the wheel.

– When you have finished cutting press “O” to

stop the disc.

Cutting

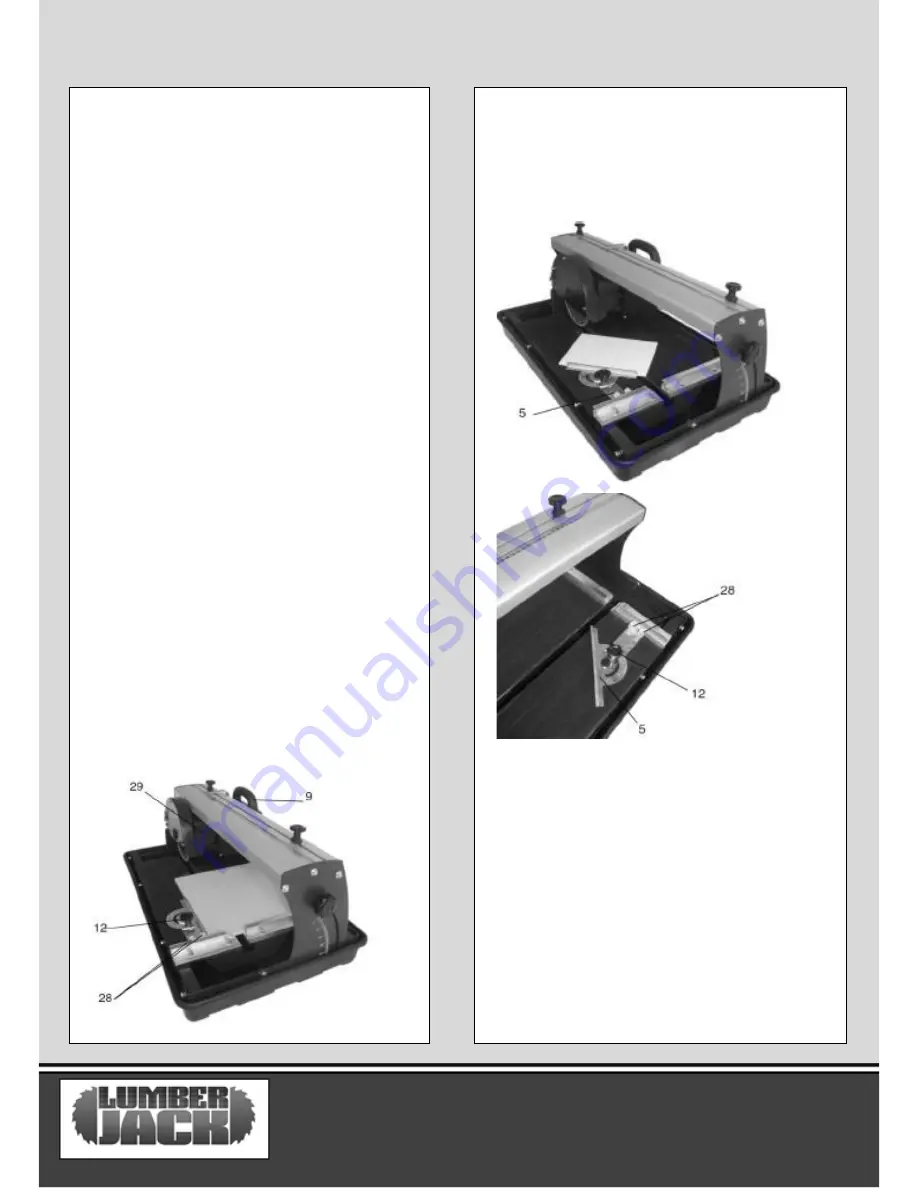

– Loosen the mitre angle screw (

12

) and set

The angle stop (

5

) to the desired angle and then

retighten Screw (

12

).

– Tighten screws (

28

) to lock the mitre angle in

place.

– Move the machine head (

29

) to the opposite

end of the track to the angle stop (

5

) with

handle (

9

).

–Position the tile against the rail fence (

6

) on the

angle stop (

5

).

– Tile set up at 90 degrees

– Tile set up at 45 degrees

TC180 07

OPERATION

Summary of Contents for TC180

Page 1: ...SAFETY AND OPERATING MANUAL WATER COOLED TILE CUTTER TC180 ORIGINAL INSTRUCTIONS TC180...

Page 14: ...TC180 12...

Page 15: ...TC180 13 PARTS LIST...

Page 16: ...TC180 14 PARTS LIST...

Page 17: ...TC180 15 PARTS DIAGRAM PART 1...

Page 18: ...TC180 16 PARTS DIAGRAM PART 2...

Page 19: ...TC180 17 PARTS DIAGRAM FULL...