EBS76 06

ASSEMBLY INSTRUCTIONS

Assembly

Avoid unintentional starting of the machine.

During assembly and for all work on the

machine, the power plug must not be

connected to the mains supply.

Carefully remove all parts included in the

delivery from their packaging.

Remove all packaging material from the machine

and the accessories provided.

Before starting the operation of the machine for

the first time, check if all parts listed in the box

content section have been supplied

Note:

Check the power tool for possible damage.

Before further use of the machine, check that all

protective devices are fully functional. Any

lightly damaged parts must be carefully checked

to ensure flawless operation of the tool. All parts

must be properly mounted and all conditions

fulfilled that ensure faultless operation.

Damaged protective devices and parts must be

immediately replaced by an authorised service

centre.

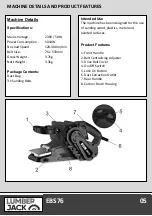

Dust Bag

We recommend that dust extraction is used at

all times when using this product.

To fit the dust bag (supplied) push it onto the

extraction port as shown below.

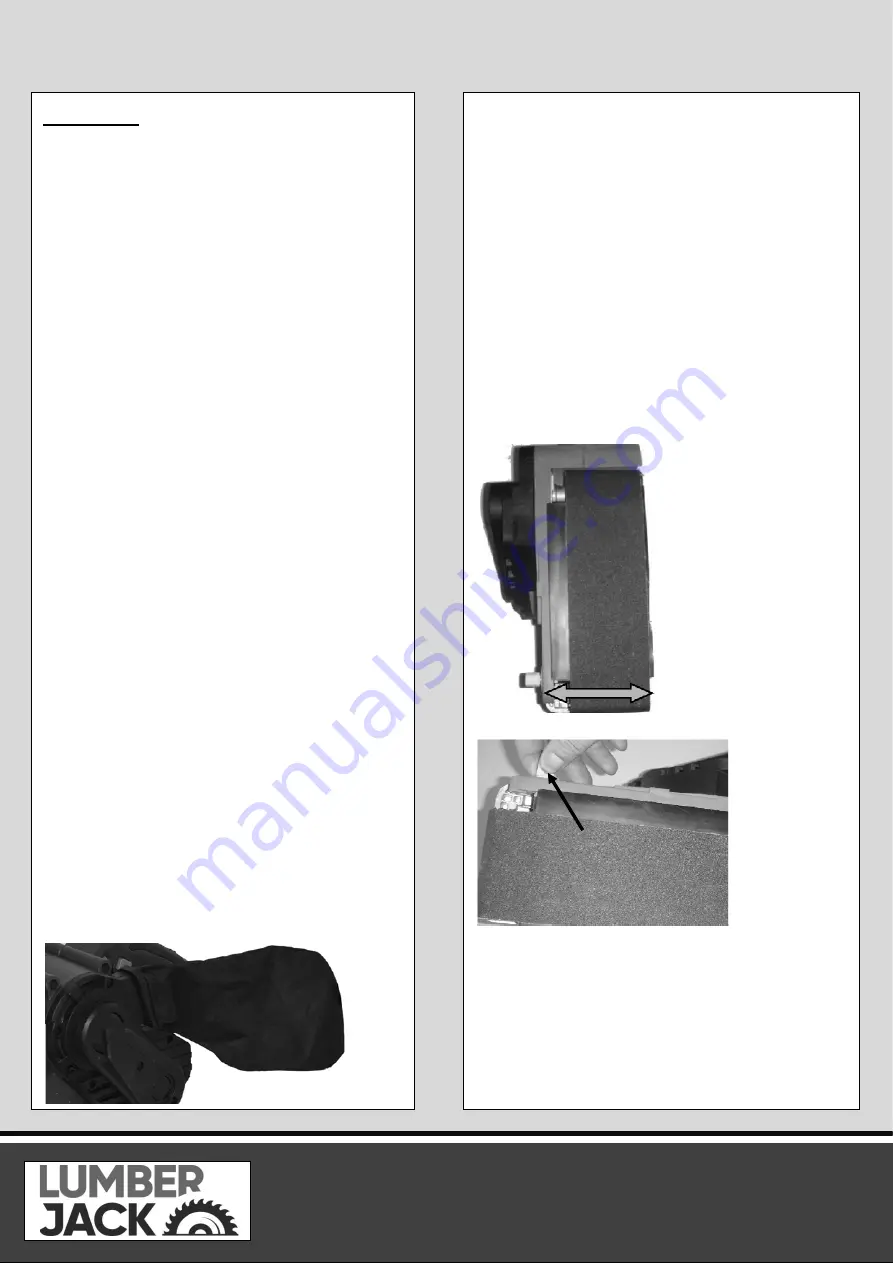

Centralizing the Belt

Always make sure that the belt is running centrally

before the machine is used. Centralizing the belt is

essential to stop it from running off the rollers

during use.

- With the belt facing the operator and the

machine on its side, pull the trigger and observe

how the belt is running. If this belt runs toward

either edge it will need adjusting.

- Turn the centralizing knob(see 1) to adjust the

belt to the centre of the rollers.