9

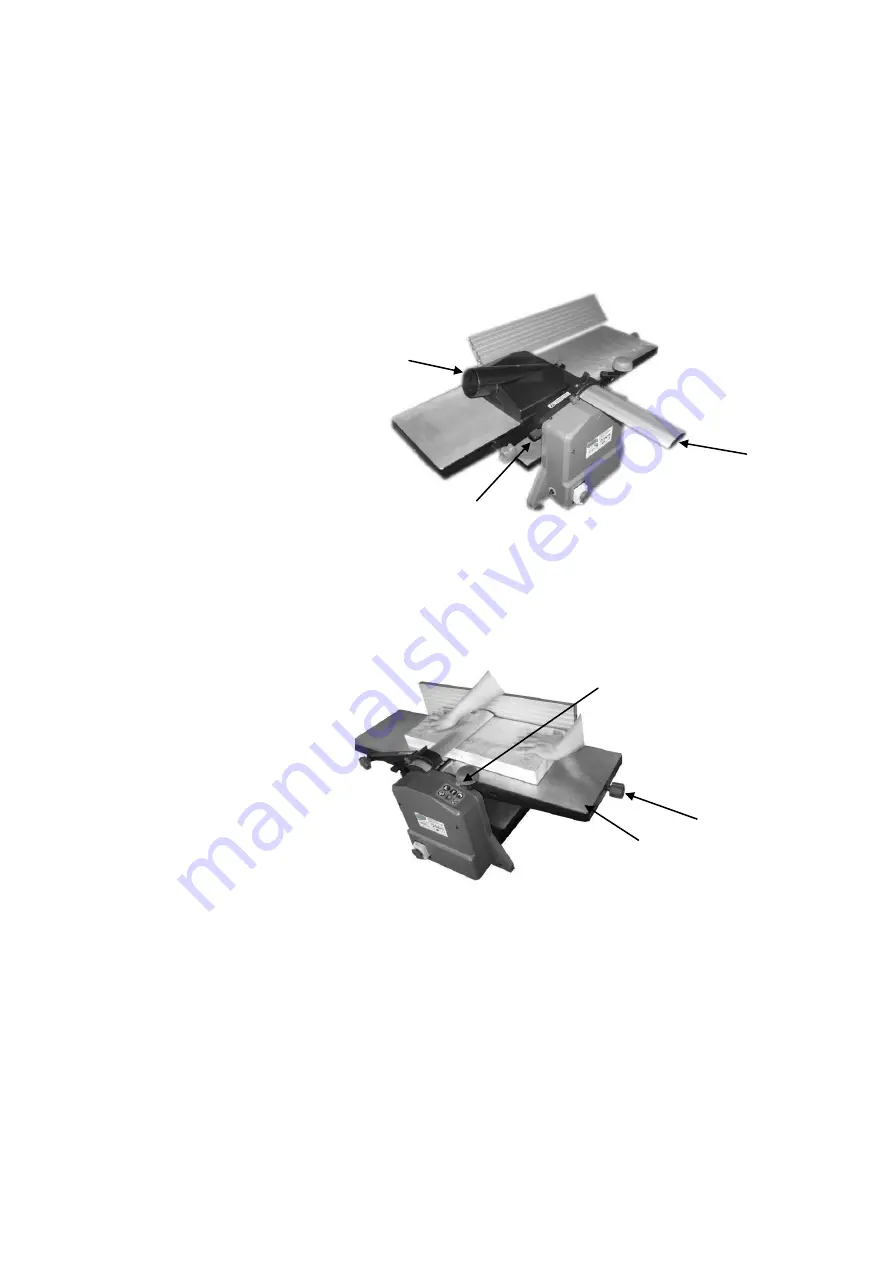

Figure 7

DUST CHUTE CONNECTION WHEN THICKNESSING:

-Slide the fence to right side, and turn to 135

°

-Remove the blade guard K and place the dust chute E(See Figure 8).

-The dust chute E is so positioned that both keys H are in line with the longitude holes G. Then push both

keys H into the longitude holes G (See Figure 6).

The minimum air velocity at the extractor connection must be 20m/s(65ft/sec) to ensure an optimum

extraction.

Figure 8

SETTING OF GUARD

Height adjustment is made with the lever mounted on the left side of the machine. After lifting the lock lever

the blade cover can slide to set the required stock width for jointing. Push lock lever down to lock guard

extrusion in position.

Refer to Figure 9. M

L

N

Figure 9

PLANING

The cutting depth is set by handle L at the front table plate N by means of the scale for cutting depth M.

Cutting depth between 0.5 and 1.5 mm (1/64~1/16 in.) will produce the best surface.

WARNING

: The part of the cutter head not used has to be covered by the blade guard.

Take up a working position so that you are always on one side of the machine away from the area directly in

front of or behind the cutterhead. Place both hands on the workpiece with the fingers. Do not hold on to the

workpiece edges.

Only workpieces should be planed which rest firmly on the machine and can be safety guided.

Refer to figure 10.

K

E

H