SG900 13

CLEANING

Warning!

Be sure to use appropriate protective gear.

-Do not use materials with a flashpoint higher than

60°C ( 140°F) . Flashpoint is the temperature that a

fluid can produce enough vapors to ignite (see

coating supplier).

- Make sure clean up area is well ventilated and free

of flammable vapors.

- Always spray outdoors when spraying cleaning

solution through sprayer.

- Do not submerse power unit.

- Use drop cloths during pouring, mixing, and

viscosity testing of materials to be sprayed to

protect your floors and anything else in the spraying

area that you wish to remain untouched.

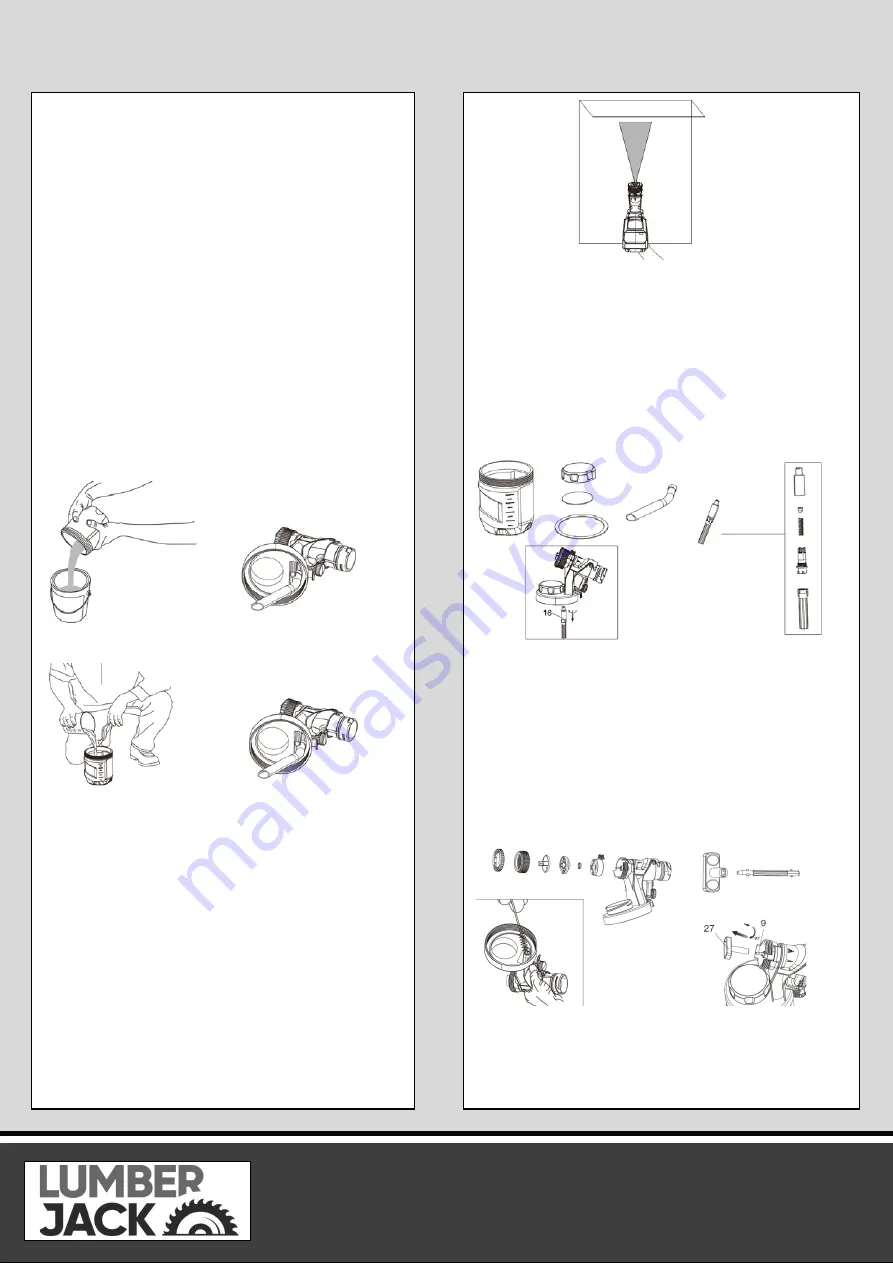

- To begin cleaning:

- Turn the power unit off and unplug the cord

- Unscrew the canister from the sprayer and

pour any remaining liquid back into the original

container .

- Pour a small amount of the appropriate

cleaning solution into the canister .

- Warm soapy water for water based materials

-Manufacturers recommended cleaning solution

for oil based materials

- Screw on the canister back to the sprayer securely

and vigorously shake the sprayer.

- Unscrew the canister and properly dispose

of

cleaning solution.

- Refill the canister with a small amount of new

cleaning solution. Screw the canister back onto

the sprayer.

-Plug in

the cord and turn on the power unit.

- Spray the cleaning solution through the

sprayer onto scrap material for 2 to 3 seconds.

- Turn the power unit off, unplug the cord

- Unscrew the canister from the sprayer.

- Remove the O-ring(#14), pickup tube(#15), check

valve (#16), and quick refill lid(#12) from the

sprayer. Clean the parts with the cleaning brush in

the appropriate cleaning solution (Fig. P).

Note:

When removing the check valve, twist the

check valve clockwise and then pull it out.(Fig P

insert)

-Unscrew the tip collar (#4) and remove all the

parts of the spray nozzle(#3,#4,#5,#6,#7.#8)

from the sprayer.

Remove the spray tip(#9) from the sprayer. (Clean

all parts with the cleaning brush in the appropriate

cleaning solution.

Be sure to clean around check valve with brush.