TAC18G 07

OPERATION

Operation

USE

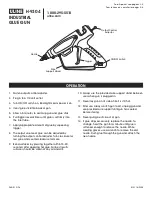

Loading staples/nails

- Turn tool upside down

- Press lever A while pulling slider B backwards

insert the staple/nail strip into magazine C with

legs facing upward

(maximal capacity 100 staples / nails)

- Push slider B against tacker head D until it

snap- locks

- When inserting a nail strip (not supplied with

the tool) tilt the tool in such a way, that the nail

strip rests against the magazine side which

corresponds with the nail symbol on tacker head

D

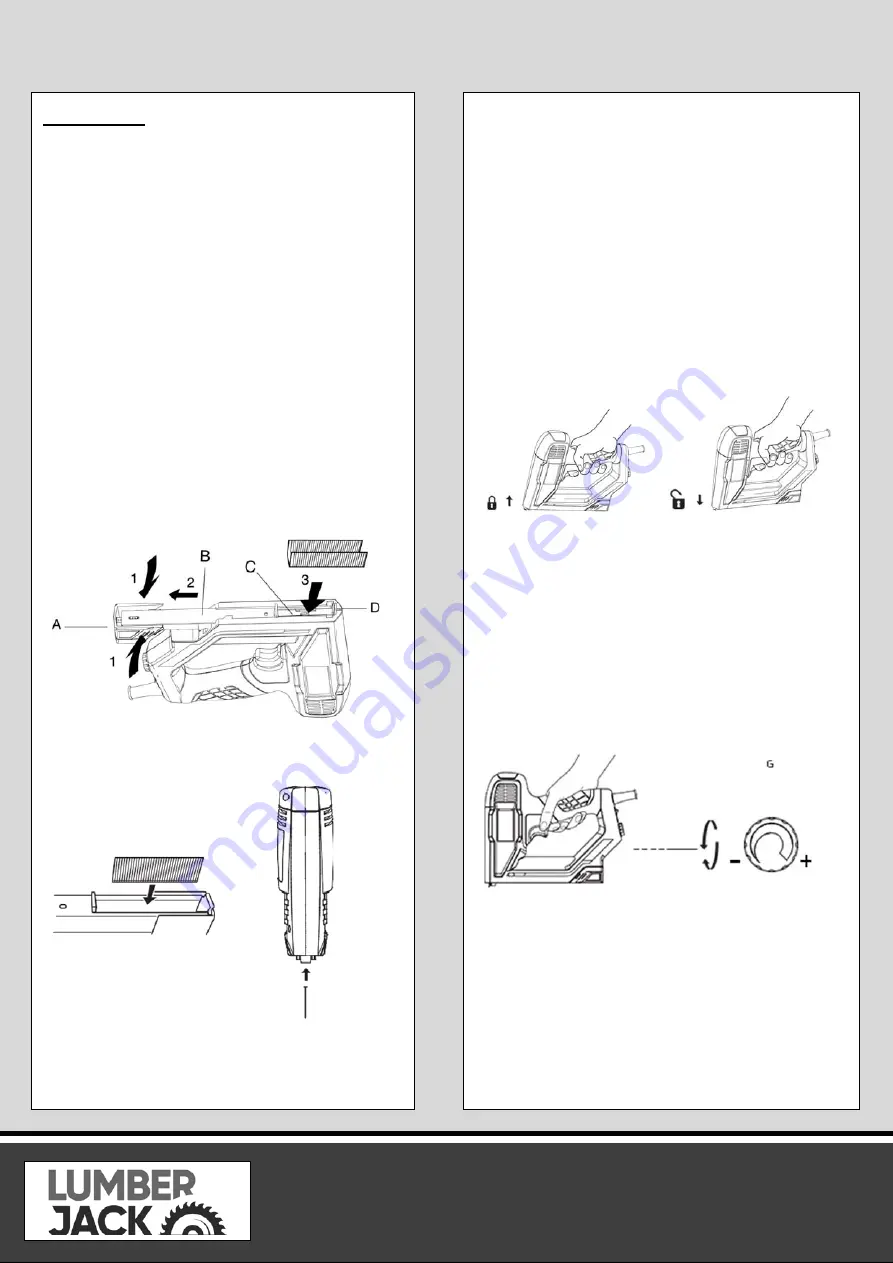

Operating the tool

- Firmly press tacker head D against the work piece

until it is pushed in a few millimetres.

- Briefly press trigger F and then release again

- Trigger F is locked as long as you do not press

tacker head D against the work piece, Thus

preventing accidental operation .

- At 20 shots/min, tacker should be allowed to cool

down after 30 minutes as it is only rated for short-

time duty.

! Remove all staples/nails from the magazine

after each use

Impact control

With knob G the required impact level can be

adjusted in steps

- Indicator G shows the selected impact level

-“-” for thin and light materials such as foils and

fabrics

-“+” for thick and tough materials such as hard

woods and walls

- Before starting a job, find the optimal impact

level by testing out on spare material