AB217 LUXEON HR30 Application Brief 20160504 ©2016 Lumileds Holding B.V. All rights reserved.

10

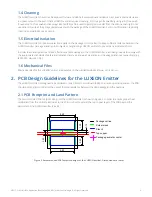

An example of a nozzle from Yamaha that is suitable for pick and place the LUXEON emitter is shown in Figure 10.

Figure 10. Example of a nozzle that fits Yamaha i-PULSE series pick and place machine.

Lumileds advises customer to take the following general pick and place guidelines into account:

a. The nozzle tip should be clean and free of any particles.

b. During setup and the first initial production runs, it is a good practice to inspect the top surface of the

LUXEON emitters under a microscope to ensure that the emitters are not accidentally damaged by the pick

and place nozzle.

5.5 Electrostatic Discharge Protection

For the part number without transient voltage suppressor (TVS) chip to protect against electrostatic discharges (ESD),

Lumileds recommends observing the following precautions when handling the LUXEON emitter:

• During manual handling always use a conductive wrist band or ankle straps when positioned on a grounded

conductive mat.

• All equipment, machinery, work tables, and storage racks that may get in contact with the LUXEON emitter should be

properly grounded.

• Use an ion blower to neutralize the static discharge that may build up on the surface and lens of the plastic housing of

the LUXEON emitter during storage and handling.

LUXEON emitters which are damaged by ESD may not light up at low currents and/or may exhibit abnormal performance

characteristics such as a high reverse leakage current, and a low forward voltage (leaky diode). It is also important to take

note that ESD can also cause latent failure, i.e. failure or symptoms as described above may not show up immediately but

until after use. Hence continuous ESD protection is needed during assembly.

5.6 JEDEC Moisture Sensitivity

The JEDEC (J-STD-020D) MSL (moisture sensitivity level) of the LUXEON emitter has unlimited floor life (MSL Level 1) when

stored under this condition: ≤30°C at 85% relative humidity.

6. Environmental Corrosion Testing

Corrosive environment can negatively affects LED performance over time. Hydrogen sulfide (H

2

S) is well known to react

with silver (tarnish) and leads to drop in light output and potentially weaken the wire bond adhesion strength over time.

To test the robustness of LUXEON HR30 emitter susceptibility to corrosive environment, two test setups were evaluated:

1. H

2

S exposure test per IEC 60068-2-43. Environmental condition: 40°C, H

2

S 15ppm, 80% RH (relative humidity) up

to 21 days.