31

4. Set Selector lever (D, Fig.18) to correct position (neutral).

5. Engage the half nut lever (A, Fig.18).

6. Make a test cut with scrap material and check results before cutting

regular material.

Compound Slide.

The compound slide (C, Fig.18) is located on top of the

cross slide and can be rotated 360°. There are calibrations in degrees (B,

Fig.18) below the rest to assist in placement of the compound to the desi-

red angle.

Gib Adjustments.

After a period of time some of the moving components

may need to be adjusted due to wear.

Saddle.

Turn gib screws on either side of the saddle at the rear to adjust

the drag on the saddle.

Cross Slide.

Turn gib screws in the front and rear of the gib to adjust the

drag of the cross slide.

Compound Slide

. Turn gib screws to adjust the drag of the compound sli-

de.

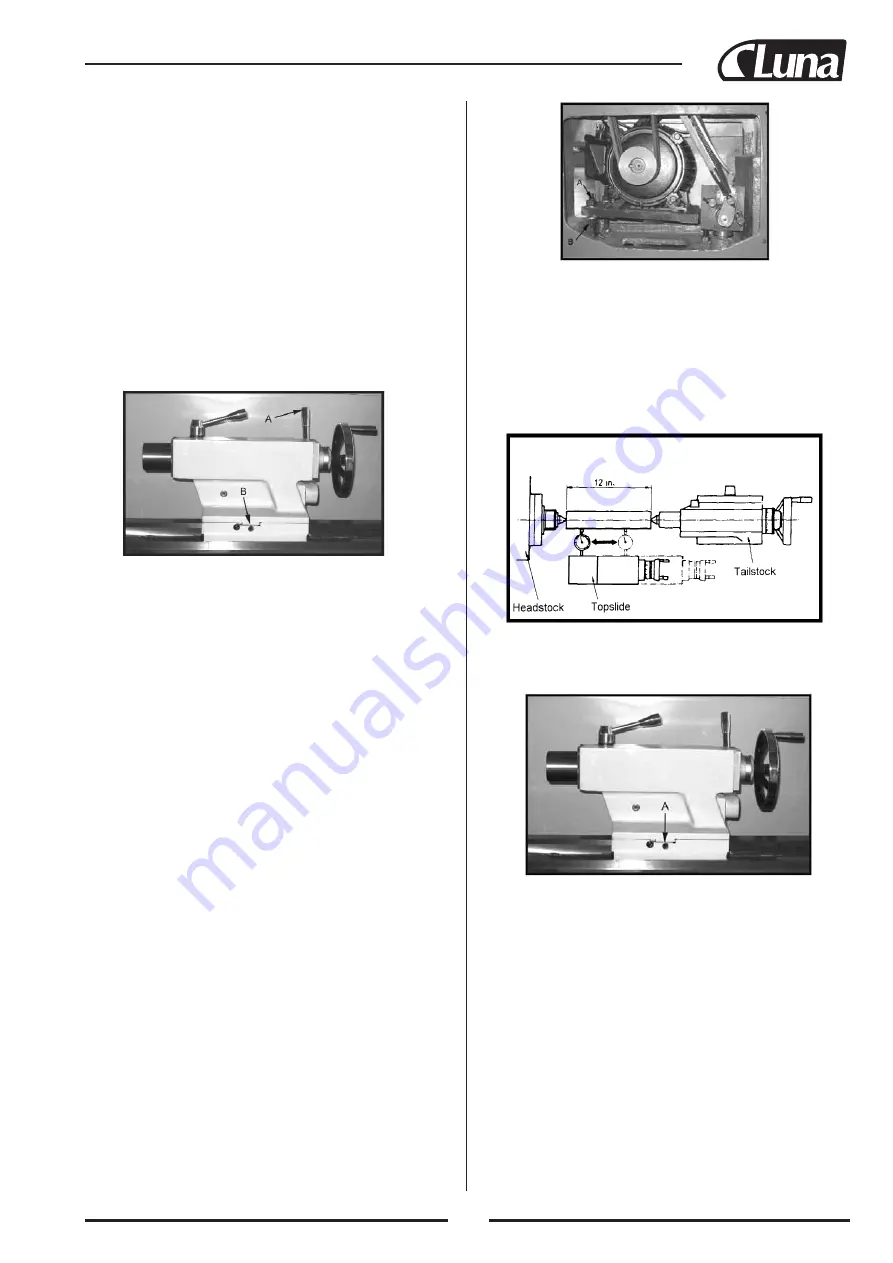

Tailstock Off-Set.

Follow the procedure below to off-set the tailstock to

cut shallow tapers:

Fig. 22

Fig. 21

Fig. 19

Fig. 20

1. Loosen tailstock in position by lowering locking handle (A, Fig.19)

and loosening hexagon head eccentric shaft.

2. Alternately loosen and tighten front and rear set screws (B, Fig.19).

Note:

Front side set screw shown.

Removing Gap Section

1. To remove the gap section, remove four hex socket cap screws, and

two hex cap bolts.

2. Tighten the hex nuts on the tapered alignment pins to loosen the pins.

Once loosened, they can be removed.

3. Gap section can now be removed.

Installing Removable Gap Section

1. Clean the bottom and the ends of the gap section thoroughly.

2. Set gap section in place and align the ends.

3. Loosen the nuts on the locating pins and push down through the gap in

to the lathe bed.

4. Replace four hex socket cap screws and tighten alternately until all are

snug.

Belt Replacement and Adjustment

1. Disconnect machine from the power source.

2. Open end gear cover, remove lower rear cover and lower side cover.

This will expose the motor and V-belts.

3. Loosen hex nut (A, Fig.20). Place scrap piece of wood under motor to

act as lever. Lift motor up and block temporarily.

4. Remove belts. Install new belts onto pulleys.

5. Lift up on motor and remove temporary blocking.

6. Tension belts by loosening nut (B, Fig.20) and tighten nut (A, Fig.20)

until light finger pressure causes approximately 3/4" deflection on each

belt.

7. Install covers and connect lathe to the power source.

Aligning Tailstock to Headstock

1. Fit a 12" ground steel bar between centers of the headstock and

tailstock (See Fig.21).

2. Fit a dial indicator to the top slide and traverse the center line of the

bar.

3. If adjustment is needed, align the tailstock using the off-set screws (A,

Fig. 22) until the tailstock is aligned.

Summary of Contents for 20758-0580

Page 2: ......

Page 73: ...71 Stand Assembly...

Page 76: ...74 Brake Assembly...

Page 78: ...76 Bed Assembly...

Page 81: ...79 Headstock Assembly I...

Page 84: ...82 Headstock Assembly II...

Page 87: ...85 Headstock Assembly III...

Page 89: ...87 Headstock Assembly IV...

Page 91: ...89 Change Gear Box Assembly I...

Page 93: ...91 Change Gear Box Assembly II...

Page 95: ...93 Quick Change Gear Box I...

Page 98: ...96 Quick Change Gear Box II...

Page 100: ...98 Quick Change Gear Box III...

Page 102: ...100 Apron Assembly I...

Page 105: ...103 Apron Assembly II...

Page 108: ...106 Apron Assembly III...

Page 110: ...108 Carriage Assembly...

Page 113: ...111 Carriage Stop Assembly...

Page 115: ...113 Four Way Tool Post...

Page 117: ...115 Tailstock Assembly I...

Page 119: ...117 Tailstock Assembly II...

Page 121: ...119 Steady Rest Assembly...

Page 123: ...121 Follow Rest Assembly...

Page 125: ...123 Coolant Work Light Assembly...

Page 130: ...128 Wiring Diagram...

Page 138: ......

Page 139: ......