7

Issue 1

Original Version

March 2016

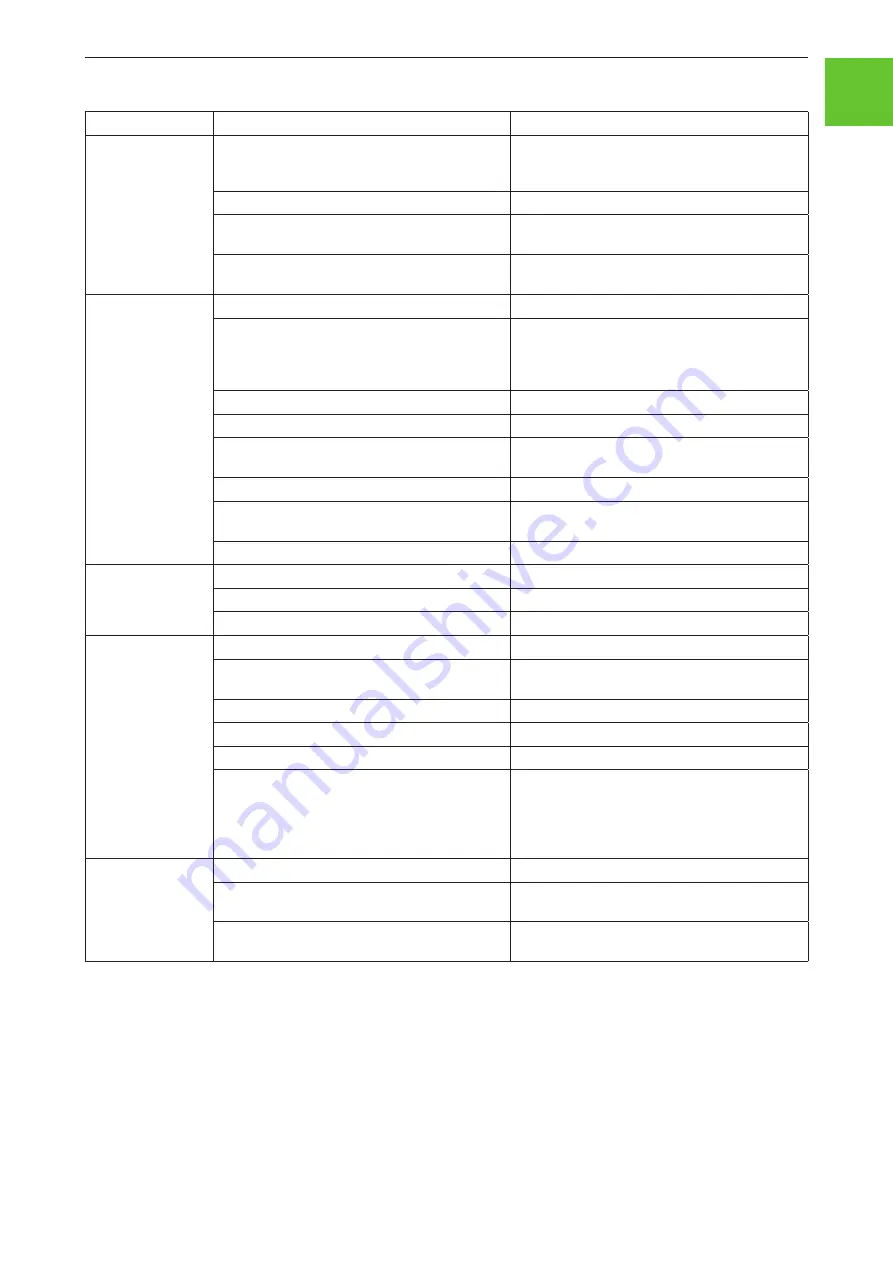

9. REMEDIES FOR HOLE MAKING

Problem

Cause

Remedy

1) Magnetic

base won’t hold

effectively

Material being cut may be too thin for efficient holding.

Attach an additional piece of metal under work-piece

where magnet will be located, or mechanically clamp

magnetic base to work-piece.

Swarf or dirt under magnet.

Clean magnet.

Irregularity on magnet contact or work-piece.

Use extreme care; file any imperfections flush to sur-

face.

Insufficient current going to magnet during drilling

cycles.

Confirm power supply and output from control unit,

check supply cable.

2) Cutter skips out of

centre-punch mark at

initiation

of cut

Magnetic base is not holding effectively.

See causes and remedies above.

Worn arbor bushing and/or ejector collar.

Replace! Only a few thousandths wear permissible.

New arbor bushing is needed.

Light pressure only is needed until a groove is cut.

The groove then serves as a stabiliser.

Too much feed pressure at start of cut.

Replace or re-sharpen. Sharpening service is available.

Cutter is dull, worn, chipped or incorrectly sharpened.

Improve centre-punch and/or replace worn parts

Poor centre-punch mark; weak pilot spring; pilot not

centred in centre-punch mark.

Replace part or parts

Worn or bent pilot, worn pilot hole.

Replace part or parts

Loose bolts on motor bushing support bracket, main

casting or loose gib adjusting set screws.

Adjust where necessary

Incorrectly re-sharpened, worn or chipped cutter.

Re-sharpen or replace.

3) Excessive drilling

pressure required

Coming down on swarf lying on surface of workpiece.

Take care not to start a cut on swarf.

Gibs out of adjustment or lack of lubrication.

Adjust setscrews, and lubricate.

Swarf accumulated (packed) inside cutter.

Clear cutter.

4) Cutter breakage

Steel swarf or dirt under cutter.

Remove cutter, clean part thoroughly and replace.

Incorrectly re-sharpened or worn cutter.

Always have a new cutter on hand to refer to for cor-

rect tooth geometry, together with instruction sheet.

Cutter skipping.

See causes and remedies (2).

Gib Strip need adjustment.

Tighten Gib Strip.

Cutter not attached tightly to arbor.

Retighten.

Insufficient use of cutting oil or unsuitable type of oil.

Inject oil of light viscosity into the coolant-inducing ring

and check that oil is being metered into cutter when

pilot is depressed. If not, check pilot groove and arbor

internally for dirt or apply oil externally. (Even a small

amount of oil is very effective).

5) Excessive cutter

wear

See cause and remedy above

Incorrectly re-sharpened cutter.

Do not use. Refer to instructions and a new cutter for

proper tooth geometry.

Exercise, insufficient or spasmodic cutting pressure.

Use sufficient steady pressure to slow the drill down.

This will result in optimum cutting speed and chip load.

UK

Summary of Contents for LB40

Page 8: ...8 Issue 1 Original Version March 2016 10 WIRING DIAGRAM UK ...

Page 9: ...9 Issue 1 Original Version March 2016 11 EXPLODED VIEW OF MACHINE UK ...

Page 10: ...10 Issue 1 Original Version March 2016 12 EXPLODED VIEW OF MOTOR AND GEARBOX UK ...

Page 24: ...24 Udgave 1 Oprindelig version Marts 2016 DK 10 LEDNINGSDIAGRAM ...

Page 25: ...25 Udgave 1 Oprindelig version Marts 2016 DK 11 SPRÆNGSKITSE MASKINE ...

Page 26: ...26 Udgave 1 Oprindelig version Marts 2016 DK 12 SPRÆNGSKITSE MOTOR OG GEARHUS ...

Page 40: ...40 Painos 1 Alkuperäinen versio Maaliskuu 2016 FI 10 KYTKENTÄKAAVIO ...

Page 41: ...41 Painos 1 Alkuperäinen versio Maaliskuu 2016 FI 11 RAJÄYTYSKUVA PORAKONE ...

Page 42: ...42 Painos 1 Alkuperäinen versio Maaliskuu 2016 FI 12 RAJÄYTYSKUVA MOOTTORI JA VAIHTEISTO ...

Page 56: ...56 Väljaanne 1 Originaalkasutusjuhend märts 2016 EE 10 ÜHENDUSSKEEM ...

Page 57: ...57 Väljaanne 1 Originaalkasutusjuhend märts 2016 EE 11 MASINA LAOTUSJOONIS ...

Page 58: ...58 Väljaanne 1 Originaalkasutusjuhend märts 2016 EE 12 MOOTORI JA REDUKTORI LAOTUSJOONIS ...

Page 72: ...72 1 izdevums Sākotnējā versija 2016 gada marts LV 10 VADOJUMA SHĒMA ...

Page 73: ...73 1 izdevums Sākotnējā versija 2016 gada marts LV 11 MAŠĪNAS SHEMATISKS ATTĒLS ...

Page 88: ...88 1 asis leidimas Pradinė versija 2016 m kovo mėn LT 10 SUJUNGIMŲ SCHEMA ...

Page 89: ...89 1 asis leidimas Pradinė versija 2016 m kovo mėn LT 11 IŠSKAIDYTASIS MAŠINOS BRĖŽINYS ...

Page 104: ...104 Wydanie 1 Wersja oryginalna Marzec 2016 PL 10 SCHEMAT POŁĄCZEŃ ...

Page 105: ...105 Wydanie 1 Wersja oryginalna Marzec 2016 PL 11 RYSUNEK ZŁOŻENIOWY WIERTARKI ...

Page 120: ...120 Utgave 1 Originalversjon Mars 2016 NO 10 KOBLINGSSKJEMA ...

Page 121: ...121 Utgave 1 Originalversjon Mars 2016 NO 11 SPRENGSKISSE AV MASKIN ...

Page 122: ...122 Utgave 1 Originalversjon Mars 2016 NO 12 SPRENGSKISSE AV MOTOR OG GIRLASSE ...

Page 136: ...136 Utgåva 1 Originalversion mars 2016 SE 10 KOPPLINGSSCHEMA ...

Page 137: ...137 Utgåva 1 Originalversion mars 2016 SE 11 SPRÄNGSKISS MASKIN ...

Page 138: ...138 Utgåva 1 Originalversion mars 2016 SE 12 SPRÄNGSKISS MOTOR OCH VÄXELLÅDA ...

Page 149: ...LUNA AB S 441 80 ALINGSÅS SWEDEN Tel 46 322 60 60 00 ...