11

0698-825 MD1xL / MD2xL - 06/2021

en

5. Operation

!

WARNING

Danger of rolling-up and pulling-in of objects!

►

Do not put any objects in the opening for the

coupling control (

→

Fig. 4).

►

Do not work on the motor with thin and loose-fit

-

ting gloves.

!

WARNING

Danger of injury due to uncontrolled restarting

of the motor!

►

The pump must not be left unattended while in

operation.

►

If the power supply fails, the motor must be

switched off.

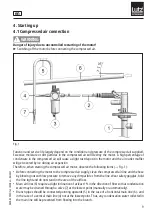

5.1 Controlling compressed air

motor MD1xL

►

For switching-on/off the motor, insert a check

valve in the compressed air line (e.g. ball valve

from Lutz accessories).

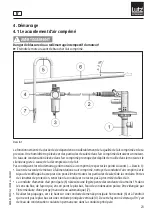

5.2 Controlling compressed air

MD2xL

►

On:

Move switch from the off-position

(

→

Fig. 5, item 1) to the required speed

(

→

Fig. 5, item 2).

Off:

Turn back the switch to Off-position.

6. Maintenance and servicing

If the compressed air motor is missing the required

power, check the following points:

Fault

Cause

Remedy

Air pressure

not sufficient

(87 psi /

6 bar)

• Compressed

air line is

leaky

• Pressure

losses

• Seal or

replace the

compressed

air line

• Enlarge

the cross-

section of the

compressed

air line

Air pressure

fluctuating

• Compressed

air line is

leaky

• Compressed

air line,

muffler or air

filter blocked

• Error during

generation of

compressed

air

• Seal or

replace the

compressed

air line

• Clean com-

pressed air

line, muffler

or air filter

• Check air

compressor

Air filter on

maintenance

unit is dirty or

blocked

• Impurities in

compressed

air

• Cleaning the

air filter

Lack of oil in

the com-

pressed air

system

• Oiler impure

or damaged

• Clean, repair

or replace

oiler

Muffler

blocked

• Impurities in

compressed

air

• Dust in the

environment

• Clean muffler

If none of the above defects is detected, the com-

pressed air motor must be repaired.