9

0698-825 MD1xL / MD2xL - 06/2021

en

4. Starting up

4.1 Compressed air connection

!

WARNING

Danger of injury due to uncontrolled restarting of the motor!

►

Switching off the motor before connecting the compressed air.

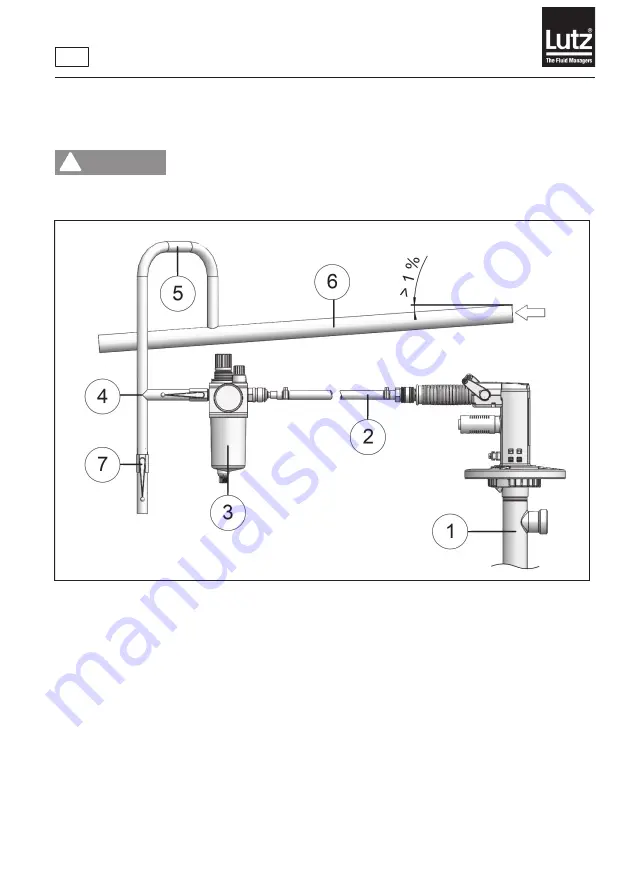

Fig. 1

Function and service life largely depend on the condition and pressure of the compressed air supplied.

Excessive moisture or dirt particles in the compressed air will destroy the motor. A high percentage of

condensate in the compressed air will cause a slight rust deposit in the motor and the air outlet muffler

will get covered by ice during air expansion.

Therefore, when starting the compressed air motor, observe the following items (

→

Fig. 1):

• Before connecting the motor to the compressed air supply, clean the compressed air line and the hose

by blowing out with low pressure to remove any dirt particles from the line. Wear safety goggles, hold

the line tight and do not stand in the area of the airflow.

• Main air lines (6) require a slight inclination of at least 1% in the direction of flow so that condensation

water may be drained through a valve (7) at the lowest point (manually or automatically).

• Branch pipes should be connected pointing upwards (5) in the case of a horizontal main line (6) - and

in the case of a vertical main line (4) not at the lowest point. Thus, any condensation water collected in

the main line will be prevented from flowing into the branch.