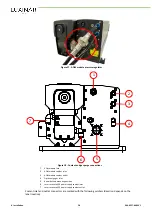

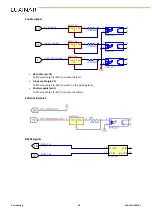

• Coolant in

• Coolant out

Important!

•

Materials used in the external cooling circuit must be chosen to avoid corrosion. Never use

aluminium, zinc, mild steel or cast iron components. Suitable materials are stainless steel,

copper, copper alloys and opaque plastics. Only use pipework that is impervious to light in

order to reduce the possibility of bacterial contamination of the cooling system.

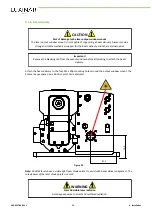

• The coolant temperature must be kept above the dew point in order to prevent formation of

condensation on internal laser components.

•

Completely drain the cooling system before shipment or storage.

6.2.4. Beam delivery optics purge gas

If the internal or external beam delivery is contaminated with fume, water vapour or debris then these

contaminants can absorb the laser energy and cause laser power fluctuations and steering of the laser

beam. In severe cases, laser optics can be contaminated and damaged.

The laser internal beam delivery is fitted with an optics purge system using contaminant-free

compressed air or nitrogen.

A non-return check valve is fitted to the internal beam delivery. The check valve opens and allows the

excess purge pressure to escape.

Once the purge pressure has dropped to the correct pressure, the valve will close automatically,

preventing dust, moisture and contaminants from entering the optical system.

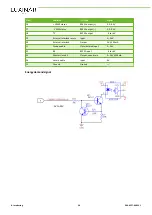

6.2.5. Electrical power connections

The laser requires a 50V DC power supply, either supplied locally or available from Luxinar. For

specifications refer to section

.

The connecting cable cross-section depends on the laser model and cable length. Refer to the following

table for cable selection.

Table 17 - DC power supply cable specification

Model

Cable length

Cross-section

SR 10 AOM

Up to 10m

16mm²

SR 10 AOM

10m up to 16m maximum

25mm²

SR 25 AOM

Up to 4m

16mm²

SR 25 AOM

4m up to 6m maximum

25mm²

906-0227-00 REV 1

29

6. Installation

Summary of Contents for SR 10 AOM

Page 1: ...USER MANUAL SR AOM series Sealed CO2 laser sources with integrated AOM...

Page 8: ...Preface iv 906 0227 00 REV 1...

Page 40: ...6 Installation 32 906 0227 00 REV 1...

Page 42: ...7 Transport and recommissioning 34 906 0227 00 REV 1...

Page 52: ...8 Interfacing 44 906 0227 00 REV 1...