Summary of Contents for LW 170 D Nautic / AL

Page 14: ...Page A 12 A LW 170 E LW 170 D Nautic Version 15 10 2019 D E S C R I P T I O N Flow chart ...

Page 15: ...Page A 13 A LW 170 E LW 170 D Nautic Version 15 10 2019 S A F E T Y P R E C A U T I O N S ...

Page 22: ...Page A 20 A LW 170 E LW 170 D Nautic Version 15 10 2019 I N S TA L L AT I O N ...

Page 31: ...Page A 29 A LW 170 E LW 170 D Nautic Version 15 10 2019 O P E R AT I O N ...

Page 39: ...Page A 37 A LW 170 E LW 170 D Nautic Version 15 10 2019 R E M E D Y I N G FA U LT S ...

Page 86: ...Page A 84 A LW 170 E LW 170 D Nautic Version 15 10 2019 M A I N T E N A N C E R E C O R D S ...

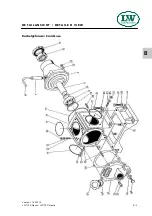

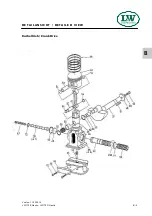

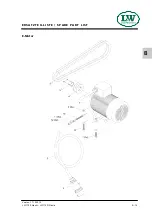

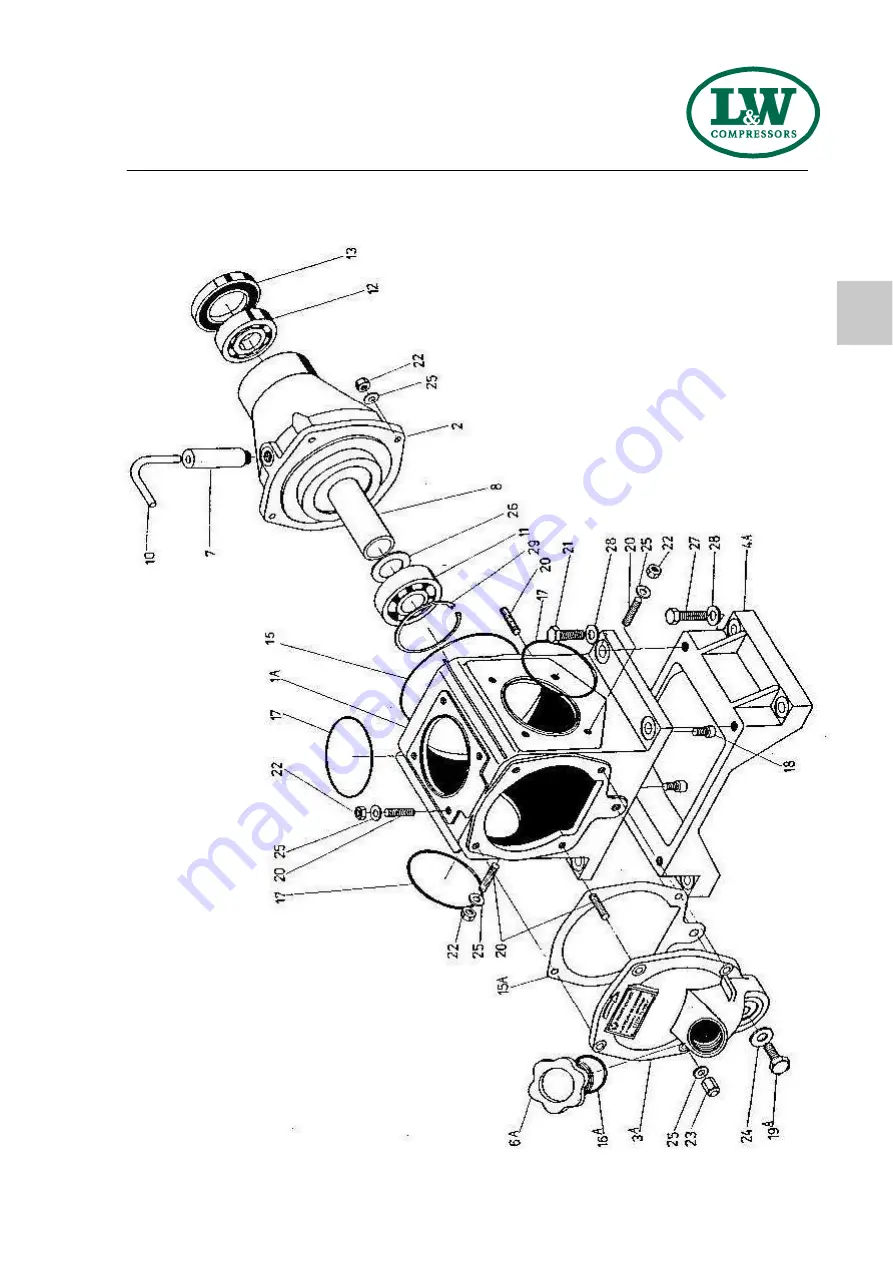

Page 95: ...B ERSATZTEILLISTEN SPARE PARTS LISTS DETAILANSICHTEN DETAILED VIEWS ...