WIRING TYPE

MDJ, MDJH, MDJB, and MDJBH models are equipped

with the LX900 board (programing and operation, page

11, field wiring, page 15). Upon installation the operator

will be in C2 mode (which means only constant pressure

will close the door).

To achieve B2 mode (where a momentary contact can be

used to close the door) an entrapment protection device

must be wired into the beam terminals according to the

wiring diagram. Once the LX900 detects there is no

obstruction it will switch to B2 Mode.

CONTROL STATION LOCATION

All operators are supplied with some type of control

station. Generally a three button station (OPEN/

CLOSED/STOP) is provided. Mount the control station

within sight of the door, at a minimum of five (5) feet

above the floor so children cannot reach it and away from

any moving parts of the door.

RADIO CONTROL

All MDJ series operators have internal antenna’s. LX900

compatible Single button, three button, or OPEN/CLOSE/

STOP (OCS) transmitter(s) are optional accessories.

While in B2 Mode, transmitters will operate the door the

same as a wall control station. Also on all MDJ series

operators, terminal strip is provided on the side of the

electrical enclosure labeled as a 24 Volt Class 2 circuit

and numbered (1,2,3). All standard radio receivers

may be wired to this terminal strip. Single channel

transmitters will then open a fully closed door, close a

fully open door, and reverse a closing door from the radio

transmitter. However, for complete door control from a

remote, a commercial three-channel radio receiver (with

connections for OPEN/CLOSE/STOP) is recommended.

ADDITIONAL ACCESS CONTROL EQUIPMENT

Locate any additional access control equipment as

desired (but so that the door will be in clear sight of the

person operating the equipment), and connect to the

control board in accordance with the LX900 WIRING

CONNECTIONS diagram. Any control with a normally

open (N.O.) isolated output contact may be connected in

parallel with the OPEN button or to the momentary switch

terminals. More than one device may be connected in this

manner. Use 18 gauge wire or larger for all controls.

External Interlock Switch

If an external interlock switch is required on the door, refer to the LX900 WIRING CONNECTIONS diagram for installation.

This switch should have a contact rating of at least 3 amps @ 24VAC. The switch must be wired in series with the STOP

and hoist switch circuit so that the door will only operate while the switch is in its closed circuit state (See wiring diagram

on page 14).

To prevent possible SERIOUS INJURY or

DEATH from a moving garage door:

•

ALWAYS keep remote controls out of

reach of children.

•

NEVER permit children to operate, or

play with remote controls.

•

Activate gate or door ONLY when it can be seen

clearly, is properly adjusted, and there are no

obstructions to door travel.

•

ALWAYS keep gate or garage door in sight until

completely closed. NEVER permit anyone to cross

path of moving gate or door.

To prevent possible SERIOUS INJURY or

DEATH

:

•

Install the control station within sight of

the door at a minimum of five (5) feet (to

prevent operation by children), but away

from the door and its hardware.

•

Install reversing sensors when the 3-button control

station is out of sight of the door or ANY other control

(automatic or manual) is used. Reversing devices are

recommended for ALL installations

•

A reversing edge MUST be installed when a receiver

is used to activate a commercial door opener.

CONTROL WIRING

MDJ, MDJH, MDJB, MDJBH

IMPORTANT NOTE:

Mount warning notice beside or below the push button

station.

WARNING

WARNING

8

MDJ, MDJH, MDJB, MDJBH

9

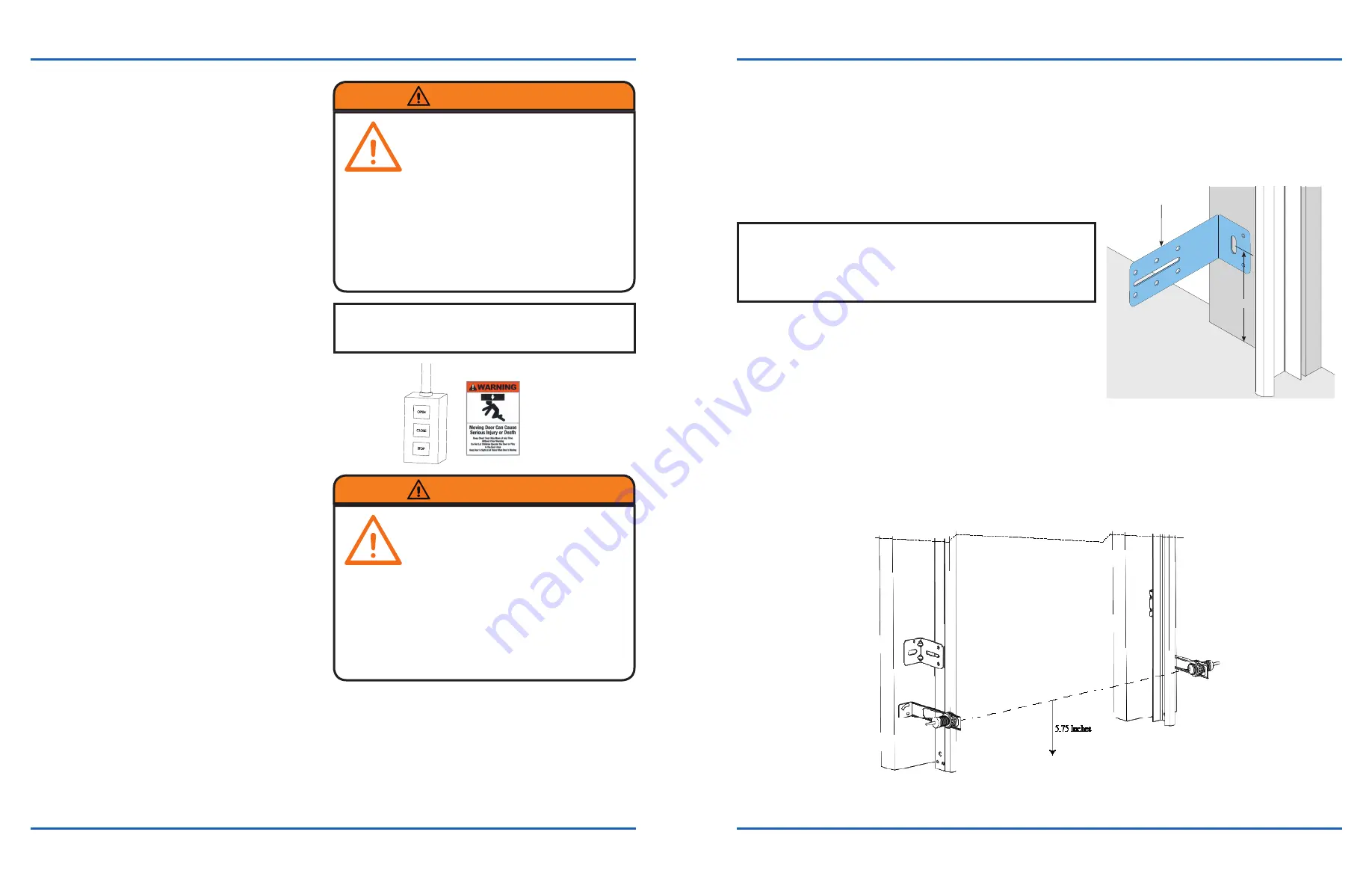

PHOTO EYE INSTALLATION

1. Make sure that power is disconnected to the system prior to installing the photo eyes.

2. Photo eyes need to be mounted inside the building. They should be mounted on either side of the door and as close

as possible to the door track to offer maximum safety precaution.

3.

Photo eyes should be mounted no more than 6 inches from the floor. Both brackets need to be installed at the same

height to allow them to align.

4.

Select a mounting location 5 inches above the floor to the centerline of the wall mounting “L” bracket. Mount the

bracket to the wall. Repeat this step on the opposite side of the door.

5. Using the wing nuts provided, attach the photo eyes to the “L”

brackets with the arrows pointing up. Do not over tighten.

6. The transmitter and the receiver both have two 22-gauge wires

coming from them. Uncoil the wires from the photo eyes and route

them to the controller. Take one wire from the transmitter and one wire

from the receiver (these wires have no polarity) and twist the stripped

ends together. Repeat on the second wire from each unit. Connect the

wires to the BEAM terminals. Again, polarity is not important.

7. At this time, you can reconnect the power to the operator. The LEDs

on both transmitter and receiver will be lit if installed and aligned

properly; the transmitter has a red LED, and the receiver has a green LED.

8.

If the photo eyes are not aligned, then the green LED on the receiver will be off. To align the photo eyes, you can

adjust the position of the transmitter or the receiver on the slot of the bracket until both LEDs are lit. Tighten the

brackets.

9. To test the photo eye system: open the door to the full open position. Close the door and as the door is closing,

obstruct the beam. The door should stop and reverse to open.

10. Test the photo eye’s function periodically.

PHOTO EYE INSTALLATION

IMPORTANT NOTE:

Identify which side of the garage door is exposed to the most

sunlight. Mount the sending unit (TX) on the side that is exposed

to the most sun. Sunlight may affect the photo sensors and this

orientation will help reduce the effect.

11

Wired Infrared Safety Sensor Bracket Installation

Tools Required: Ratchet wrench, tape measure, power drill, 1/4 inch drill bit, 1/2 inch socket, pencil

IMPORTANT:

BOTH WALL BRACKETS MUST BE MOUNTED AT THE SAME HEIGHT FOR PROPER ALIGNMENT.

IMPORTANT:

IDENTIFY WHICH SIDE OF THE GARAGE DOOR IS EXPOSED TO THE MOST SUNLIGHT.

MOUNT THE SENDING UNIT (UNIT WITH RED LED) ON THE SIDE WHICH IS EXPOSED TO THE MOST SUN.

SUNLIGHT MAY AFFECT THE SAFETY SENSORS AND THIS ORIENTATION WILL HELP REDUCE THE EFFECT.

Wall Mounting Bracket

5”

Note: Use the following steps to install sensors on both sides of the door

Select and mark with a pencil a mounting location no more than 5 inches above the floor to the

center line of the wall mounting bracket.

The safety sensors should be mounted as close

to the door track or inside edge of the door as

possible to offer maximum entrapment

protection. It is very important that both

brackets be mounted at the same height for

proper alignment.

Drill pilot hole using a1/4 inch drill bit. Attach

bracket to wall using provided 5/16 x 1-1/2 lag

screw and nail as illustrated.

In some installations it may be necessary to

attach a wooden spacer to the wall to achieve

the required alignment.

After both brackets are mounted attach sensor

units to brackets using wing nuts. Be sure arrow

on sensors are pointing up.

Arrow on the sensor

pointing up

17

FIGURE 8

FIGURE 9