Turn on the power to the operator. Test all controls and safety devices to make sure they are working properly. Refer to

the previous instructions in this manual to make necessary adjustments.

TESTING THE SYSTEM

IMPORTANT NOTE:

Do not leave operator power on unless all safety and entrapment devices have been tested and are working properly.

Be sure you have read and understand all Safety Instructions in this manual.

IMPORTANT NOTE:

Be sure the owner or person(s) responsible for the operation of the door have read and understand the Safety

Instructions, know how to electrically operate the door in a safe manner, and know how to use the manual disconnect

operation of the door system.

MAINTENANCE SCHEDULE

To avoid SERIOUS PESONAL

INJURY or DEATH from

electrocution

, disconnect

ALL electric power BEFORE

performing ANY maintenance.

WARNING

13

MDJ, MDJH, MDJB, MDJBH

MDJ, MDJH, MDJB, MDJBH

12

IMPORTANT NOTE:

ITEM

PROCEDURE

EVERY

3

MONTHS

EVERY

6

MONTHS

Drive Chain

Check for excessive slack, adjust as needed.

Lubricate.

Sprockets

Check for set screw tightness.

Clutch

Check, adjust as needed.

Belt

Check condition & tightness.

Fasteners

Check, tighten if needed.

Manual Disconnect

Check & operate.

Brake (if present)

Check, adjust as needed.

•

•

•

•

•

•

•

•

Do not...

•

Use grease or silicone

spray

•

Lubricate motor

•

Lubricate Clutch or V-belt

Do...

•

Disconnect ALL electric power

BEFORE performing any

maintenance.

•

Use SAE 30 Oil.

•

Inspect and service whenever

a malfunction is observed or

suspected.

To prevent possible SERIOUS INJURY or DEATH,

install reversing sensors when the 3-button control

station is out of sight of the door or any other control

(automatic or manual) is used. Reversing devices are

recommended for ALL installations.

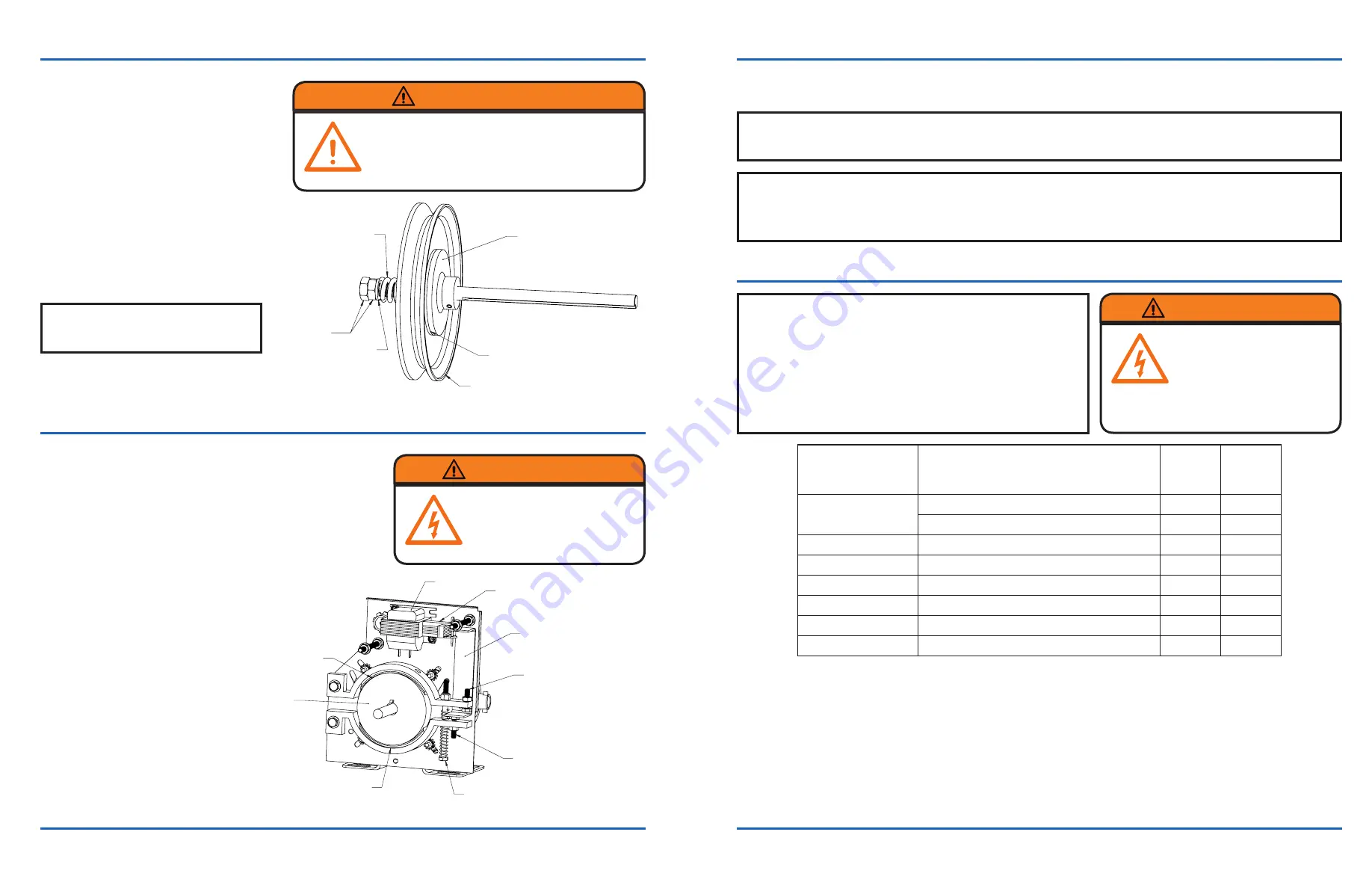

CLUTCH ADJUSTMENT

1. Loosen the adjustment jam nuts until

there is little tension on the clutch

spring.

2. Tighten the inner jam nut gradually until

there is just enough tension to permit

the operator to move the door smoothly

but to allow the clutch to slip if the

door is obstructed. When the clutch is

properly adjusted, it should generally be

possible to stop the door by hand during

travel.

3. Tighten the outer jam nut and lock the

nuts in place by tightening them against

one another.

IMPORTANT NOTE:

The adjustable friction clutch is NOT an

automatic reversing device.

Clutch Hub

Fiber Disc

Spring

Adjustment

Jam Nuts

Washer

Clutch Pulley

On models LDJB and LDJBH a brake is supplied from the

factory. It is designed to stop and hold the door in position

whenever power is removed from the motor.

On first installation the brake should not need adjustment. The

brake operation should be inspected every 3 months. As the

brake pads wear, adjustments need to be made to maintain

proper operation.

With the power disconnected to the

operator, carefully try to rotate the large

drive pulley by hand. The brake should

be engaged and it should be very

difficult to turn.

While pushing the solenoid plunger

in by hand, there should now be

clearance between the brake pads

and the drum (approximately .020")

allowing the pulley to rotate freely. To

achieve the proper operation, adjust

the upper and lower pad spacing bolts

(A&B) accordingly.

BRAKE ADJUSTMENT

Solenoid

Drum

Lower Brake Pad

Upper Brake Pad

Pivot Plate (C)

Spring Tension

Adjustment Bolt

Upper Pad Spacing Bolt (A)

Lower Pad Spacing Bolt (B)

Solenoid Plunger

WARNING

To avoid SERIOUS PERSONAL

INJURY or DEATH from

electrocution

, DISCONNECT

electric power BEFORE

performing any maintenance

WARNING