Lynx NGT-9000s

Installation Manual

2.3.5.5 Installation

1.

Use the following information to the extent necessary to install the directional antenna.

•

Standard installation practices prescribed in FAA Advisory Circular 43.13 must be followed.

•

The installer must ensure the immediate antenna installation area is clean and prepared so that

the antenna is electrically bonded (metal-to-metal contact) to the aircraft. To provide optimum

bonding through the mounting holes, prepare the surfaces with Alodine No. 1001.

•

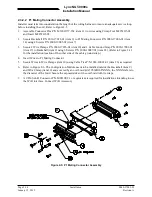

To facilitate mounting to the airframe, the dimensions shown in Figure 2-16 can be used to

locate and drill mounting and connector access holes.

•

Connection to the antenna should be made in accordance with the system interconnect diagram

Figure 2-3.

NOTE

A doubler plate (not supplied) is required to reinforce the aircraft skin.

2.

Connect each of the three antenna cables. Check to ensure that each cable is connected to the correct

antenna connector. Each connector/cable has a matching color band (see note paragraph.).

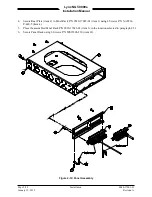

3.

Attach the antenna to the aircraft, with the special adapter plate and o-ring, using 10-32 hardware

provided. See Figure 2-17.

NOTES

1.

Before installing the antenna on an aircraft remove the tape, which

holds the O-RING gasket in place during shipment (refer to SL-206).

If the O-ring is in a separate bag, remove and install it in the O-ring

groove on the bottom of the antenna.

2.

For pressurized aircraft, use a sealant that meets the requirements of

SAE AMS-S-8802 such as Flamemaster CS3204 class B. For non-

pressurized aircraft, use a non-corrosive sealant that meets the

physical requirements of MIL-A-46146 such as General Electric

RTV162.

0040-17001-01

Installation

Page 2-27

Revision A

January 15, 2015