CHANGE OF ADDRESS/OWNERSHIP

If your address has changed or if you are the new owner of the snow-

mobile, be sure to notify BRP by either:

– Notifying an authorized Lynx dealer/distributor.

–

North America Only:

calling at 1 888 272-9222.

– Mailing one of the change of address cards on the following

pages at one of the BRP addresses indicated in the

CONTACT

US

section of this guide.

In case of change of ownership, please join a proof that the former

owner agreed to the transfer.

Notifying BRP, even after the expiration of the limited warranty, is

very important as it enables BRP to reach the snowmobile owner

if necessary, like when safety recalls are initiated. It is the owner’s

responsibility to notify BRP.

STOLEN UNITS:

If your personal snowmobile is stolen, you should

notify BRP or an authorized Lynx dealer. We will ask you to provide

your name, address, phone number, the vehicle identification num-

ber and the date it was stolen.

_________________

269

Summary of Contents for RADIEN Crossover E-TEC Series

Page 12: ...TABLE OF CONTENTS 10 __________________...

Page 13: ...SAFETY INFORMATION ____SAFETY INFORMATION ___ 11...

Page 65: ...VEHICLE INFORMATION __________________ 63...

Page 162: ...VEHICLE TRANSPORTATION This page is intentionally blank 160 _________________...

Page 163: ...MAINTENANCE _________________ 161...

Page 170: ...MAINTENANCE PROCEDURES mmo2014 004 001_g TYPICAL 1 Brake fluid reservoir 168 _________________...

Page 215: ...STORAGE This page is intentionally blank _________________ 213...

Page 216: ...STORAGE 214 _________________...

Page 217: ...TECHNICAL INFORMATION _________________ 215...

Page 223: ...EC DECLARATION OF CONFORMITY DoC_LYNX_MY21 _________________ 221...

Page 239: ...SPECIFICATIONS VEHICLE This page is intentionally blank _________________ 237...

Page 240: ...SPECIFICATIONS VEHICLE 238 _________________...

Page 241: ...TROUBLE SHOOTING _________________ 239...

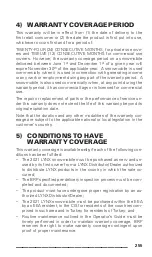

Page 249: ...WARRANTY _____ 247...

Page 267: ...CUSTOMER INFORMATION _____ 265...

Page 272: ...CHANGE OF ADDRESS OWNERSHIP This page is intentionally blank 270 _________________...

Page 273: ...CHANGE OF ADDRESS OWNERSHIP CHANGEADD SKI _________________ 271...

Page 274: ...CHANGE OF ADDRESS OWNERSHIP This page is intentionally blank 272 _________________...

Page 275: ...CHANGE OF ADDRESS OWNERSHIP CHANGEADD SKI _________________ 273...

Page 276: ...CHANGE OF ADDRESS OWNERSHIP This page is intentionally blank 274 _________________...

Page 277: ...CHANGE OF ADDRESS OWNERSHIP CHANGEADD SKI _________________ 275...

Page 278: ...CHANGE OF ADDRESS OWNERSHIP This page is intentionally blank 276 _________________...

Page 279: ...CHANGE OF ADDRESS OWNERSHIP NOTES _________________ 277...

Page 280: ...CHANGE OF ADDRESS OWNERSHIP NOTES 278 _________________...

Page 281: ...CHANGE OF ADDRESS OWNERSHIP NOTES _________________ 279...

Page 282: ...CHANGE OF ADDRESS OWNERSHIP NOTES 280 _________________...