CONTROLS, INSTRUMENTS AND EQUIPMENT

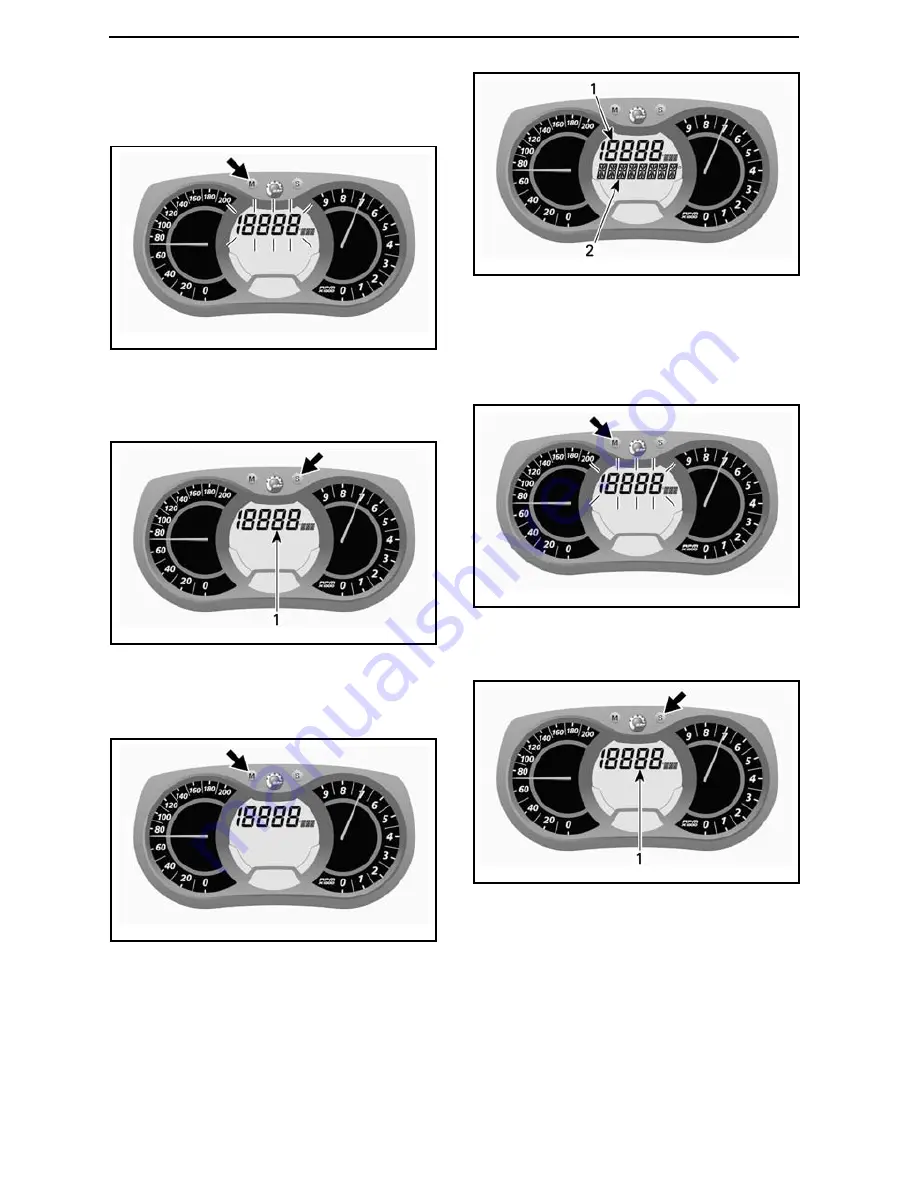

Use MODE (M) button to select the de-

sired display, then proceed as follows:

mmo2007-009-066_m

While display is flashing, press the

SET (S) button to select speedometer

mode.

mmo2007-009-066_n

1. Speedometer mode

Press the MODE (M) button to confirm

selection or wait 5 seconds.

mmo2007-009-066_o

B) Tachometer (RPM)

In addition of the analog type tachome-

ter, RPsM can also be displayed via the

multifunction display.

Engine RPM can be displayed on dis-

play 1 or display 2.

mmo2007-009-066_q

MULTIFUNCTION DISPLAY

1. Display 1

2. Display 2

Use MODE (M) button to select the de-

sired display, then proceed as follows:

mmo2007-009-066_m

While display is flashing, press SET (S)

button to select RPM mode.

mmo2007-009-066_n

1. RPM mode

Press the MODE (M) button to confirm

selection or wait 5 seconds.

32

______________

Summary of Contents for RAVE RS SERIES

Page 1: ......

Page 8: ...TABLE OF CONTENTS 6 _______________ ...

Page 9: ...SAFETY INFORMATION ________ SAFETY INFORMATION ________ 7 ...

Page 25: ...VEHICLE INFORMATION _______________ 23 ...

Page 63: ...MAINTENANCE INFORMATION _______________ 61 ...

Page 87: ...TECHNICAL INFORMATION _______________ 85 ...

Page 89: ..._______________ 87 ...

Page 93: ...TROUBLESHOOTING _______________ 91 ...

Page 98: ...MONITORING SYSTEM This page is intentionally blank 96 ______________ ...

Page 99: ...WARRANTY _______________ 97 ...

Page 104: ...102 ______________ ...

Page 105: ...CUSTOMER INFORMATION ______________ 103 ...

Page 108: ...CHANGE OF ADDRESS OWNERSHIP This page is intentionally blank 106 ______________ ...

Page 109: ...CHANGE OF ADDRESS OWNERSHIP ______________ 107 ...

Page 110: ...CHANGE OF ADDRESS OWNERSHIP 108 ______________ ...

Page 111: ...CHANGE OF ADDRESS OWNERSHIP ______________ 109 ...

Page 112: ...CHANGE OF ADDRESS OWNERSHIP 110 ______________ ...

Page 113: ......