DISASSEMBLY & INSPECTION

With proper maintenance and lubrication, normal life expectancy for gears, bearings, and seals can be achieved.

However, over a period of time these parts must be repaired or replaced to maintain the efficiency of your blower.

This section is written in a way that will allow you to completely disassemble your blower. The inspection of certain

repairable or replaceable parts is referred to at the point of disassembly where these parts are exposed. If at any

point of inspection, repair or replacement is deemed necessary, appropriate instruction will be given to achieve

these repair or replacement is deemed necessary, appropriate instruction will be given to achieve these repairs or

replacements.

Remove the oil drain plug [18] in the bottom of the gear cover [5] and drain the oil. Take out eight cap screws [16]

and remove the gear cover. It may be necessary to tap the sides with a mallet or wooden block to break the seal

joint.

Gears are not exposed for visual inspection. Items in brackets [ ] are referenced to item numbers on page 16.

Inspect the gears for the following:

•

Broken Teeth

•

Chipped Teeth

•

Uneven Wear

•

Excessive Wear

•

Any Other Abnormalities

WARNING:

Before performing any repair

or replacement, disconnect

and lock out power.

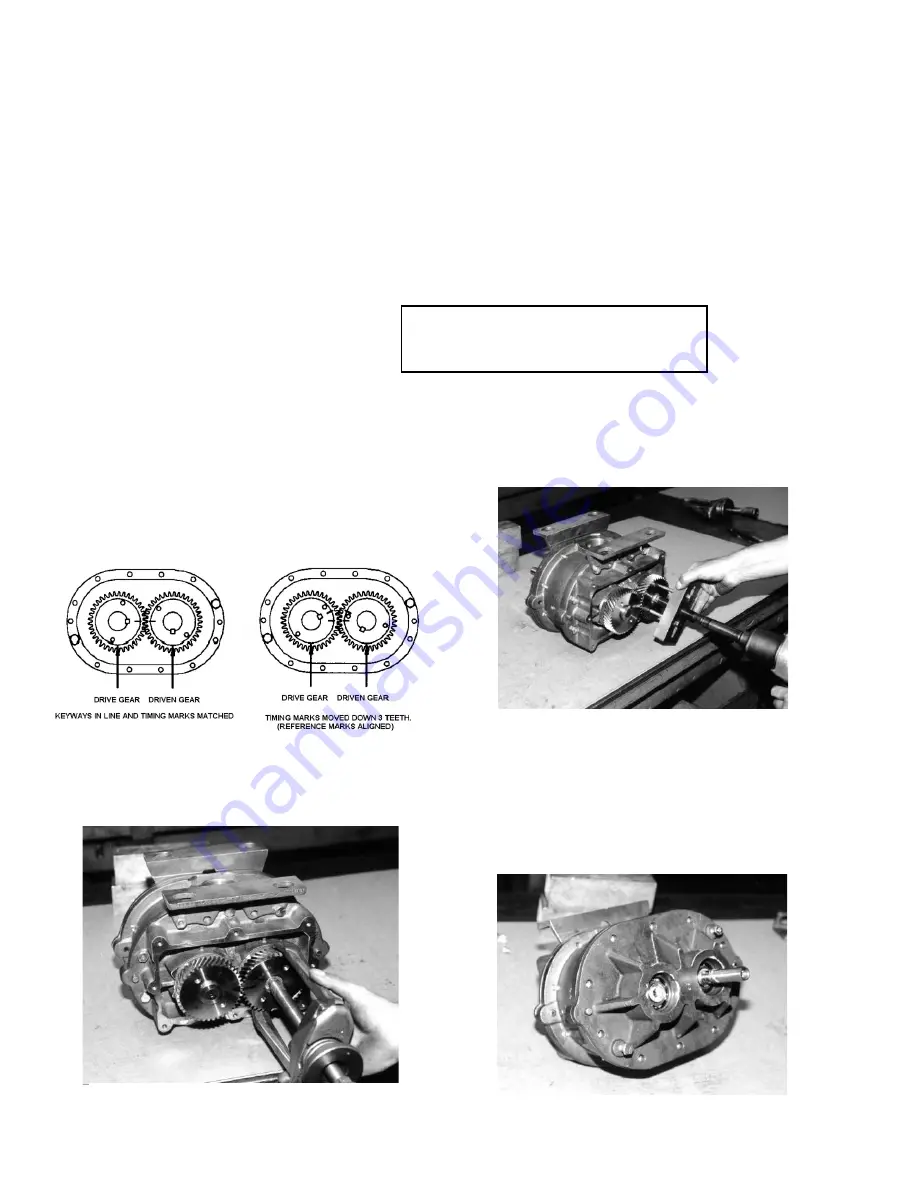

Figure 1. Timing Gear Alignment

Figure 3. Pulling Drive Gear with Bar Puller

Figure 2. Pulling Driven Gear with Jaw Puller

Align reference marks and use puller to pull the driven

gear. (Gear on right side). (Refer to Figure 2 below)

BLOWER DISASSEMBLY

Position blower with the drive gear on the left when

facing the gears. Remove socket head screws and

washers. [tems 29 & 26].

Align timing marks and count four (4) teeth down and

place reference marks on the gears. (Refer to Figure 1

below)

Use puller to remove drive gear. A bar puller (Refer to

Figure 3 below) or jack screws can be used.

Figure 4. Pulling Drive End Plate

Remove shim and spacer. [Items 28 & 30]

Turn blower around and remove grease cover [Item 10]

Remove eight (8) cap screws. [Item 15]

Use jackscrews to remove end plate. (Refer to Figure 4

below)

10

Summary of Contents for COMPETITOR PLUS 2002

Page 20: ...NOTES...