WARRANTY

Subject to the terms and conditions hereinafter set forth and set forth in General Terms of Sale, Tuthill Pneumatics Group (the

seller) warrants products and parts of its manufacture, when shipped, and its work (including installation and start-up) when

performed, will be of good quality and will be free from defects in material and workmanship. This warranty applies only to Seller's

equipment, under use and service in accordance with seller's written instructions, recommendations and ratings for installation,

operating, maintenance and service of products, for a period as stated in the table below. Because of varying conditions of

installation and operation, all guarantees of performance are subject to plus or minus 5% variation. (Non-standard materials are

subject to a plus or minus 10% variation)

THIS WARRANTY EXTENDS ONLY TO BUYER AND/OR ORIGINAL END USER, AND IN NO EVENT SHALL THE SELLER

BE LIABLE FOR PROPERTY DAMAGE SUSTAINED BY A PERSON DESIGNATED BY THE LAW OF ANY JURISDICTION AS

A THIRD PARTY BENEFICIARY OF THIS WARRANTY OR ANY OTHER WARRANTY HELD TO SURVIVE SELLER'S

DISCLAIMER.

All accessories furnished by Seller but manufactured by others bear only that manufacturer's standard warranty.

All claims for defective products, parts, or work under this warranty must be made in writing immediately upon discovery and,

in any event within one (1) year from date of shipment of the applicable item and all claims for defective work must be made in

writing immediately upon discovery and in any event within one (1) year from date of completion thereof by Seller. Unless done

with prior written consent of Seller, any repairs, alterations or disassembly of Seller's equipment shall void warranty. Installation

and transportation costs are not included and defective items must be held for Seller's inspection and returned to Seller's

Ex-works point upon request.

THERE ARE NO WARRANTIES, EXPRESSED, IMPLIED OR STATUTORY WHICH EXTEND BEYOND THE DESCRIPTION

ON THE FACE HEREOF, INCLUDING WITHOUT LIMITATION, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS OF PURPOSE.

After Buyer's submission of a claim as provided above and its approval, Seller shall at its option either repair or replace its

product, part, or work at the original Ex-works point of shipment, or refund an equitable portion of the purchase price.

The products and parts sold hereunder are not warranted for operation with erosive or corrosive material or those which may

lead to build up of material within the product supplied, nor those which are incompatible with the materials of construction. The

Buyer shall have no claim whatsoever and no product or part shall be deemed to be defective by reason of failure to resist erosive

or corrosive action nor for problems resulting from build-up of material within the unit nor for problems due to incompatibility with

the materials of construction.

Any improper use, operation beyond capacity, substitution of parts not approved by Seller, or any alteration or repair by others

in such manner as in Seller's judgment affects the product materially and adversely shall void this warranty.

No employee or representative of Seller other than an Officer of the Company is authorized to change this warranty in any way

or grant any other warranty. Any such change by an Officer of the Company must be in writing.

The foregoing is Seller's only obligation and Buyer's only remedy for breach of warranty, and except for gross negligence, willful

misconduct and remedies permitted under the General Terms of Sale in the sections on

CONTRACT PERFORMANCE,

INSPECTION AND ACCEPTANCE

and the

PATENTS

Clause hereof, the foregoing is

BUYER'S ONLY REMEDY HEREUNDER

BY WAY OF BREACH OF CONTRACT, TORT OR OTHERWISE, WITHOUT REGARD TO WHETHER ANY DEFECT WAS

DISCOVERED OR LATENT AT THE TIME OF DELIVERY OF THE PRODUCT OR WORK.

In no event shall Buyer be entitled to

incidental or consequential damages. Any action for breach of this agreement must commence within one (1) year after the cause

of action has occurred.

January, 2001

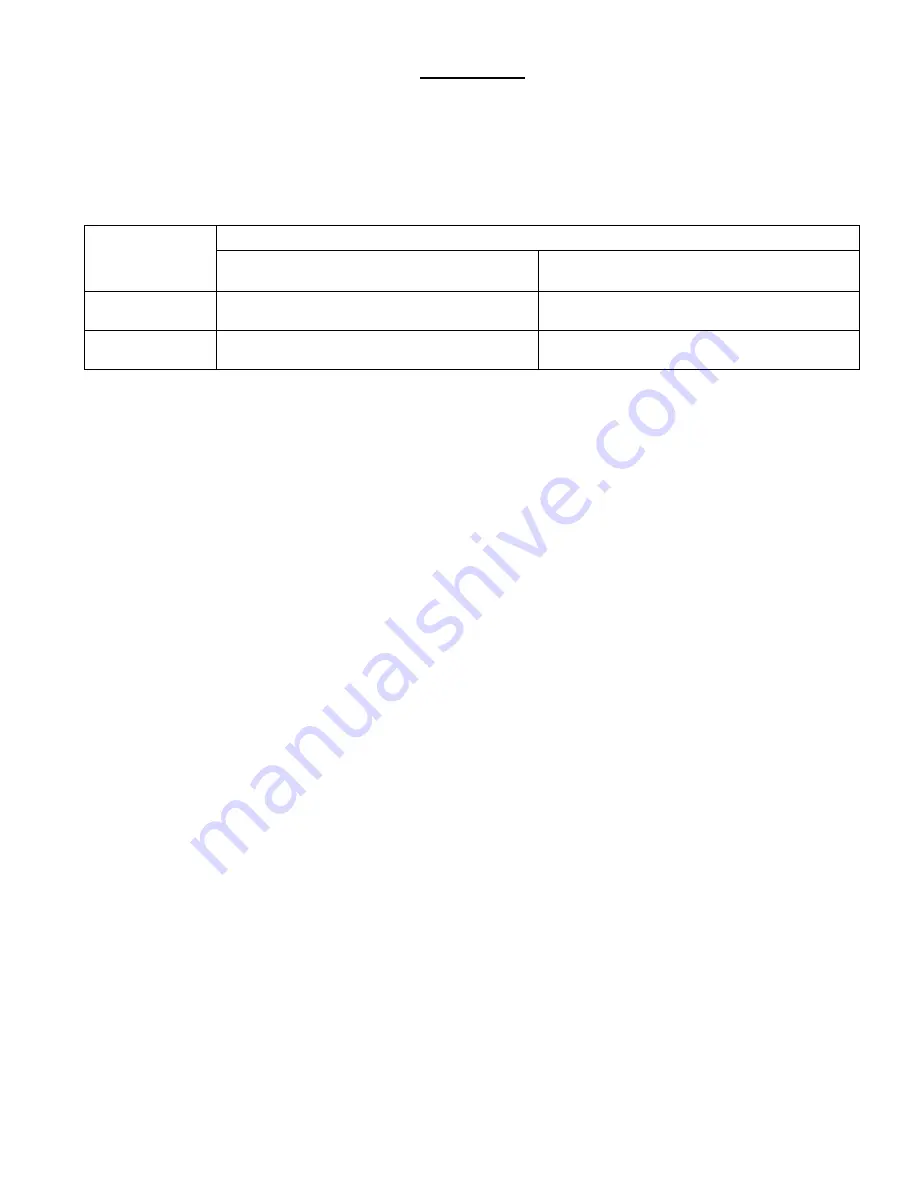

Product

Type of Application

Type

Atmospheric Air or Process Air

Without Liquids Present

Process Gases Other Than Air,

or Any Liquid Injected Application

New

24 months from date of shipment, or 18 months

after initial startup date, whichever occurs first

18 months from date of shipment, or 12 months

after initial startup date, whichever occurs first

Repair

3 months from date of shipment, or remaining

warranty period, whichever is greater

3 months from date of shipment, or remaining

warranty period, whichever is greater

17

Summary of Contents for COMPETITOR PLUS 2002

Page 20: ...NOTES...