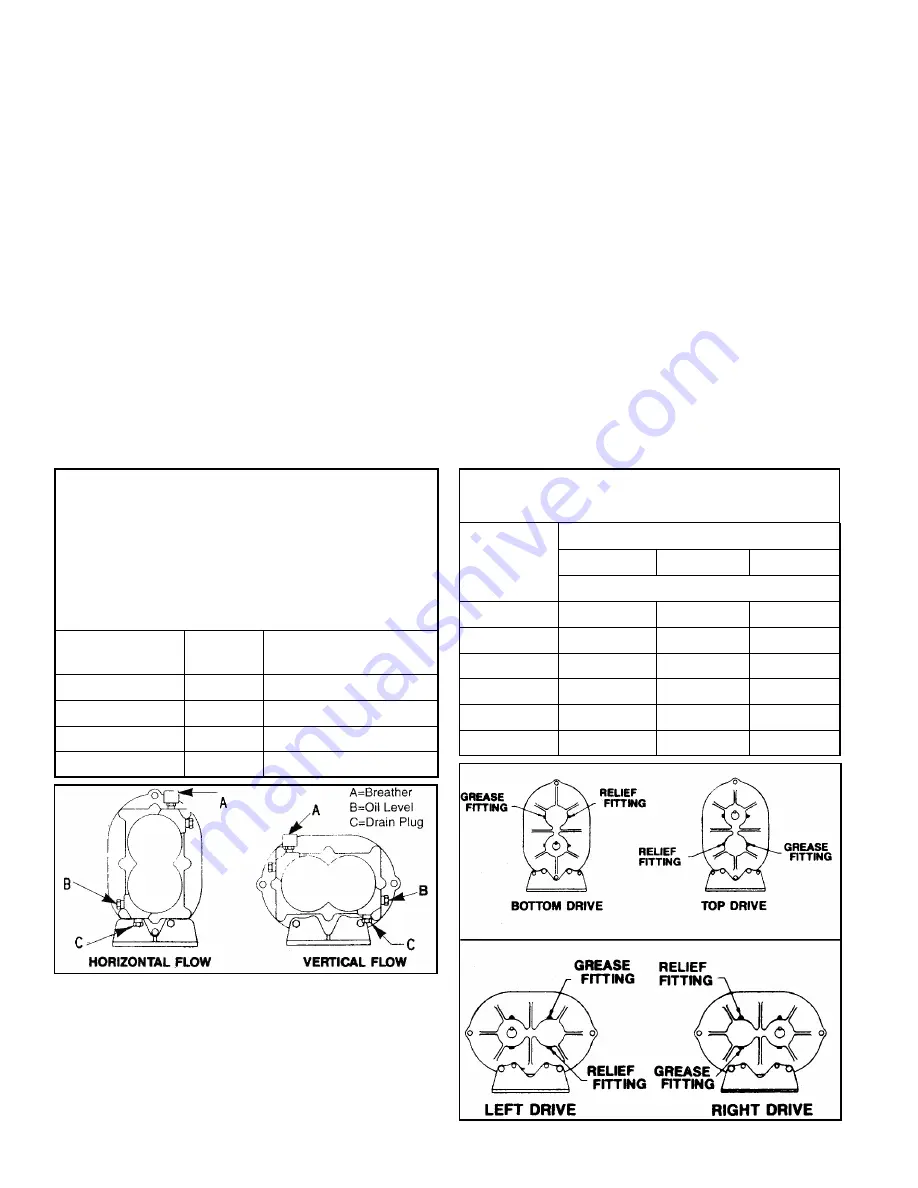

LUBRICATION

The bearings at the drive shaft end of the blower are grease lubricated. The timing gears and bearings at the other end

are lubricated by the lower timing gear (when in the horizontal flow configuration) acting as a oil slinger, carrying oil to

the upper timing gear and providing splash lubrication for the bearings. Both timing gears act as stingers when the

blower is in the vertical flow configuration.

Use a good grade industrial type anti-rust, oxidation and foam inhibited, non-detergent oil.

FILLING PROCEDURE

To fill the gear housing, remove the oil breather* (A) and oil level plug (B) on the gear end. Fill the gear housing until

oil drips out of the oil level hole. Replace plugs in their respective holes.

*Models 2002 and 2004 do not have oil breathers. In this case, remove plug to fill.

WARNING:

Do not start the blower until you are sure oil has been put in the gear housing.

GREASE LUBRICATED BEARINGS

Service drive end bearings at regular intervals. (See "Suggested Lubrication Intervals for Grease Lubricated Bearings"

below.) Use NLGI #2 premium grade, petroleum base grease with high temperature resistance and good mechanical

stability Using a pressure gun, force new grease into each bearing until traces of clean grease come out of the relief

fitting.

CAUTION:

To avoid blowing out the drive shaft seal, do not inject grease too rapidly.

6

SUGGESTED LUBRICATION INTERVALS

FOR GREASE LUBRICATED BEARINGS

SPEED

OPERATING

HOURS

PER DAY

IN

8

16

24

RPM

GREASING INTERVALS IN WEEKS

750-1000

7

4

2

1000-1500

5

2

1

1500-2000

4

2

1

2000-2500

3

1

1

2500-3000

2

1

1

3000 and up

1

1

1

LUBRICATION INSTRUCTIONS FOR

OIL LUBRICATED GEARS AND BEARINGS

Add fresh oil as required to maintain proper level. Drain

and refill after the first 100 hours of operation and

thereafter every 1,000 hours of operation under normal

service, more frequently depending on the type of oil

and oil operating temperature. Use a good quality oil.

AMBIENT

TEMPERATURE

OIL

GRADE

OIL VISCOSITY RANGE

SSU AT 100° F

Above 90° F

SAE 50

1000-1200

32° F to 90° F

SAE 40

700-1000

0° F to 32° F

SAE 30

500-700

Below 0° F

SAE 20

300-500

Summary of Contents for COMPETITOR PLUS 2002

Page 20: ...NOTES...