48NDVA

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-9441-A Rev.9 P. 2 / 9

■

AND ....

• The unit is designed to function as soon as power is sup-

plied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data

sheet.

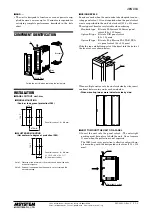

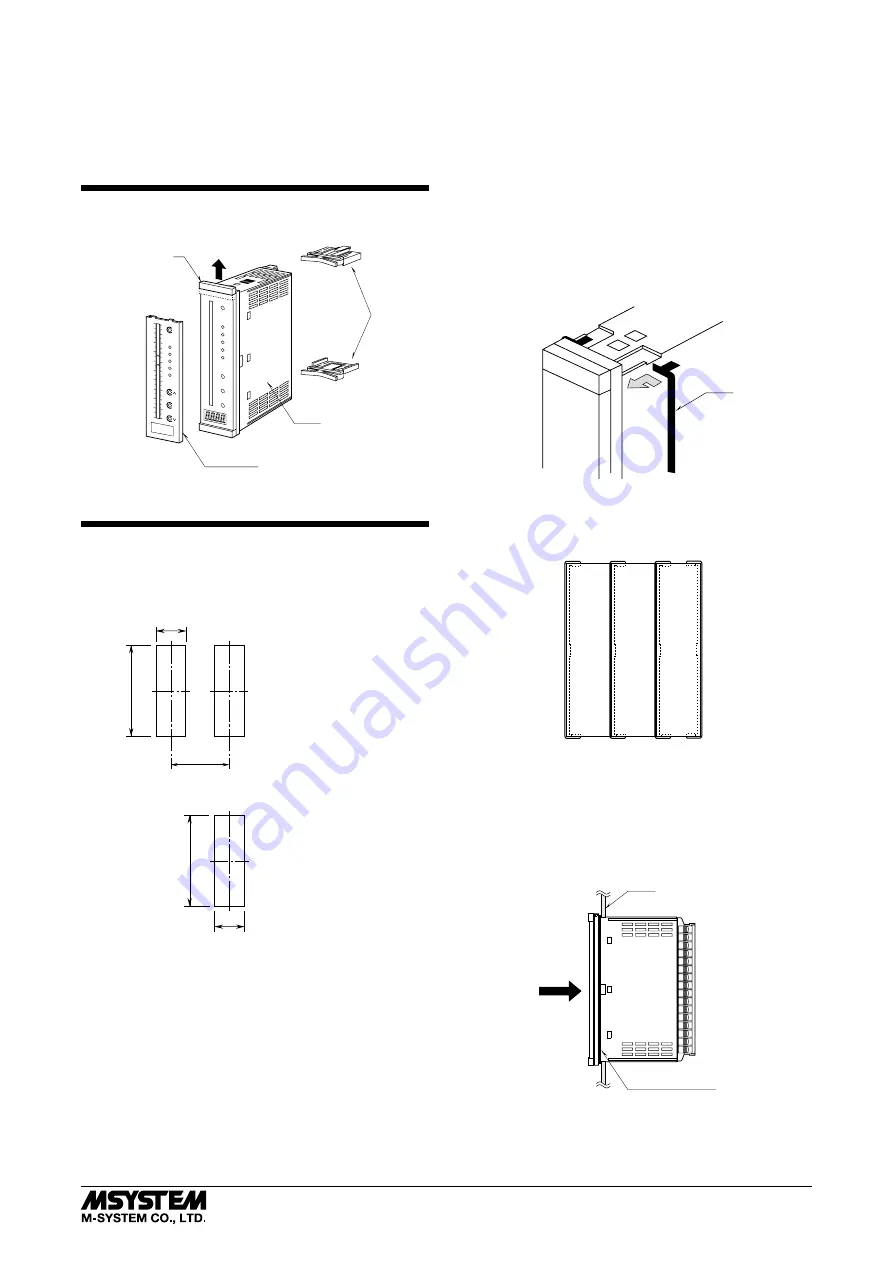

COMPONENT IDENTIFICATION

50

40

30

20

10

0

10

20

30

40

50

m

3

/h

%

mA

100 SET

H

S

P

Z

L

90

80

70

60

50

40

30

20

10

0

M

Brackets

Body

A

Scale Plate

Pull up the part ‘A’ when replacing the scale plate.

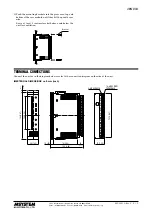

INSTALLATION

■

PANEL CUTOUT unit: mm

138

+1 –0

31.5

Note 1: Observe at the minimum of 3 cm above and below the units

for heat dissipation.

Note 2: No bezel is needed when the panel is cut according to the

above drawings.

Panel thickness: 1.6 – 8.0 mm

■

SINGLE MOUNTING

(Conform to degree of protection IP65)

138

+1 –0

L

Panel thickness: 1.6 – 8.0 mm

L = {31.5 + 36 × (N – 1)}

(N : number of units)

+1

–0

■

CLUSTERED MOUNTING

(Not conform to degree of protection IP65)

+1

–0

61.5 min.

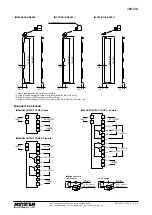

■

USING BEZELS

Bezels are used when the unit needs to be adapted to an ex-

isting panel cutout. It is not required when the panel cutout

size is as specified in the unit’s data sheet (31.5 × 138 mm).

Three types of bezels are selectable when ordering.

Standard type: Fits into M-System’s 48 Series’ panel

cutout (38 × 139.5 mm)

Option /D type: Fits into DIN panel cutout

(33 × 138 mm)

Option /F type: Fits into Fuji Electric PAJ, PAK, PBA,

etc, panel cutout (44 × 138 mm)

Slide the top and bottom parts of the bezel into the back of

the front cover as shown below.

Bezel

When multiple units are to be clustered side by side, insert

one bezel between two units as shown below.

• When mounting two or more indicators side by side:

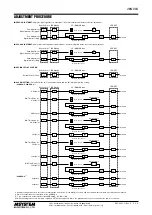

■

HOW TO MOUNT THE UNIT ON A PANEL

1) Insert the unit into the panel cutout. The watertight

packing must be in place to hold the unit. Do not remove

it even when the protection is not required.

The IP65 front cover protection is effective only with sin-

gle mounting, with the designated cutout size (31.5 ×138

mm).

Panel

Watertight Packing