R3-NF3

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-8288 Rev.2 P. 3 / 8

■

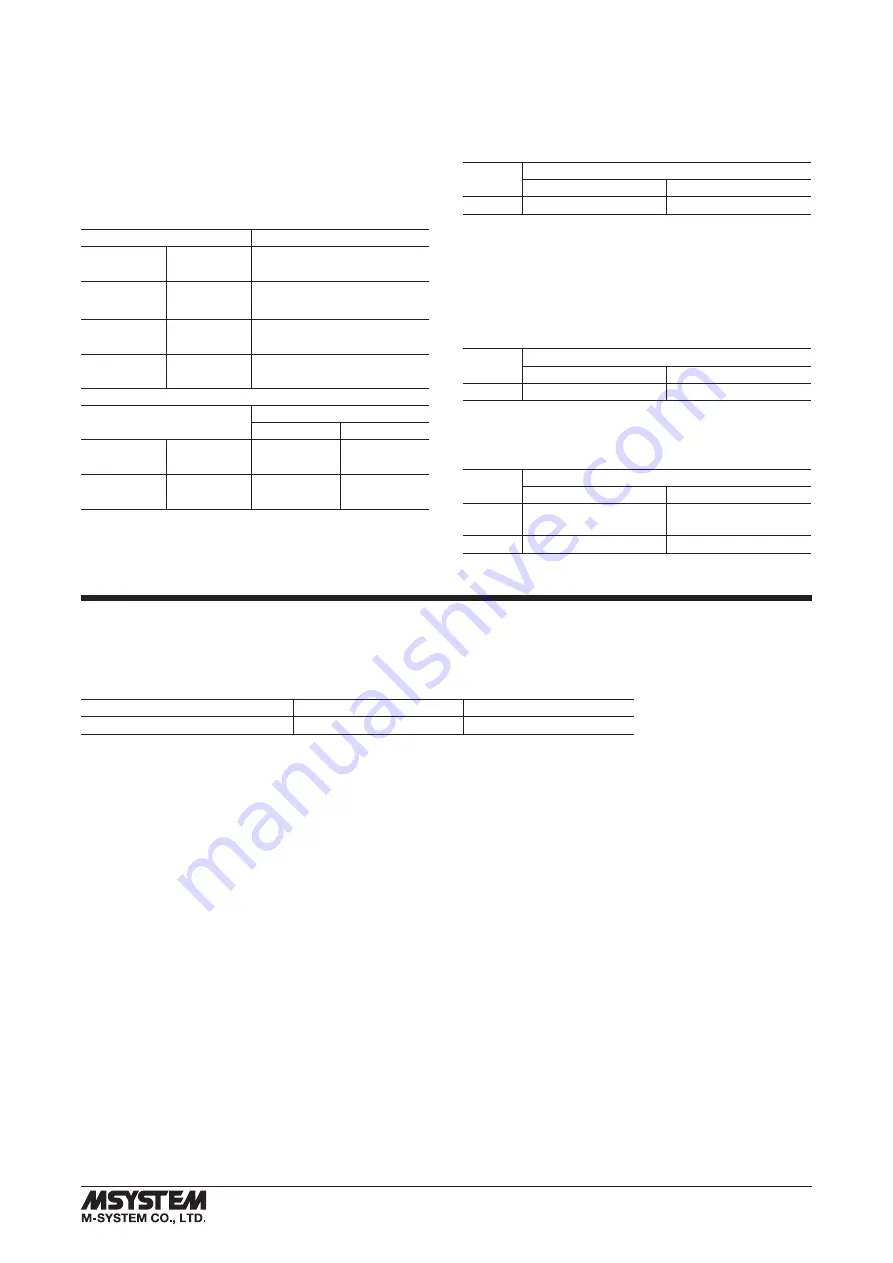

SIDE DIP SW

(*)Factory Setting

• Data Allocation setting: SW1, SW2

Data Allocation Type* must be assigned to each I/O module

slot position to specify how many data areas (four types) are

to be occupied by each.

Two bits from SW1 and SW2 are assigned to each position,

and data areas can be specified from the slot No. 1 through

8. Setting for No. 9 and later slots is identical to No. 8.

SW ASSIGNMENT

SLOT

SW1-1

SW1-2

1

SW1-3

SW1-4

2

SW1-5

SW1-6

3

SW1-7

SW1-8

4

SW2-1

SW2-2

5

SW2-3

SW2-4

6

SW2-5

SW2-6

7

SW2-7

SW2-8

8

SW SETTING

DATA ALLOCATION

DIGITAL

ANALOG

OFF

OFF

1

1

ON

OFF

2

4

OFF

ON

4

8

ON

ON

Unused

16

* Refer to the specifications of the related series for the Data

Allocation Type of I/O modules.

• Dual Communication setting: SW3-1

When two network modules are mounted, one must be

‘Main’ (OFF) network and the other must be ‘Sub’ (ON) net-

work. For single communication, the network module must

always be set to ‘Main’ (OFF).

SW

DUAL COMMUNICATION

MAIN

SUB

SW3-1

OFF (*)

ON

• Input Error Data setting: SW3-2

Hold

: When the communication from an input module is lost

due to the input module error, the network module holds the

signal and stands by until the communication recovers.

Set to ‘0’

: When the communication from an input module

is lost due to the input module error, the network module

outputs ‘0.’

SW

INPUT ERROR DATA

HOLD

SET ‘0’

SW3-2

OFF (*)

ON

• LED Function setting: SW3-4

Functions assigned to the front RUN and ERR LEDs can

be selected.

SW3-4

LED FUNCTION

RUN

ERR

OFF (*)

Green when normal

Green ON or blinking

when abnormal

ON

Red when receiving

Red when transmitting

Note: Be sure to set unused SW3-3 to OFF.

PC CONFIGURATOR

The following parameter items can be set with using PC Configurator Software (model: R3CON).

Refer to the users manual for the R3CON for detailed operation of the software program.

■

NETWORK MODULE SETTING

PARAMETER

SETTING RANGE

DEFAULT SETTING

Time (no communication time)

0.2 – 3200.0 (sec.)

3.0 (sec.)