R3-TC2

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-8468 Rev.3 P. 6 / 37

SYSTEM CONFIGURATIONS & CONTROL EXAMPLES

Relay

Oven

Heater Power

R3–BS

R3–NM3

R3–TC2

■

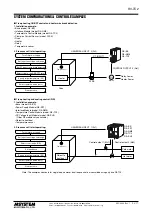

1 loop heating ON/OFF control and heater wire break detection

1. Installation example:

• Base (model: R3–BS)

• Interface Module (model: R3–NM3)

• Temperature Control Module (model: R3–TC2)

• Clamp-on Current Sensor (model: CLSE)

• Oven

• Heater

• Relay

• Temperature sensor

2. Proccess until start operating:

CLSE

Relay Power

CONTROL OUTPUT 3 (Do1)

UNIVERSAL INPUT 2 (Pv2)

CT INPUT 1

Ry

Heater

Turn ON power supply

Set input sensor type and range

Set CT input to wire break detection

Select control mode (ON/OFF Control)

Specify target temperature (SP)

Select operation mode (auto)

Start operation

Temp. Sensor

R3–BS

R3–PS1

R3–NM3

R3–TC2

R3–SV4

■

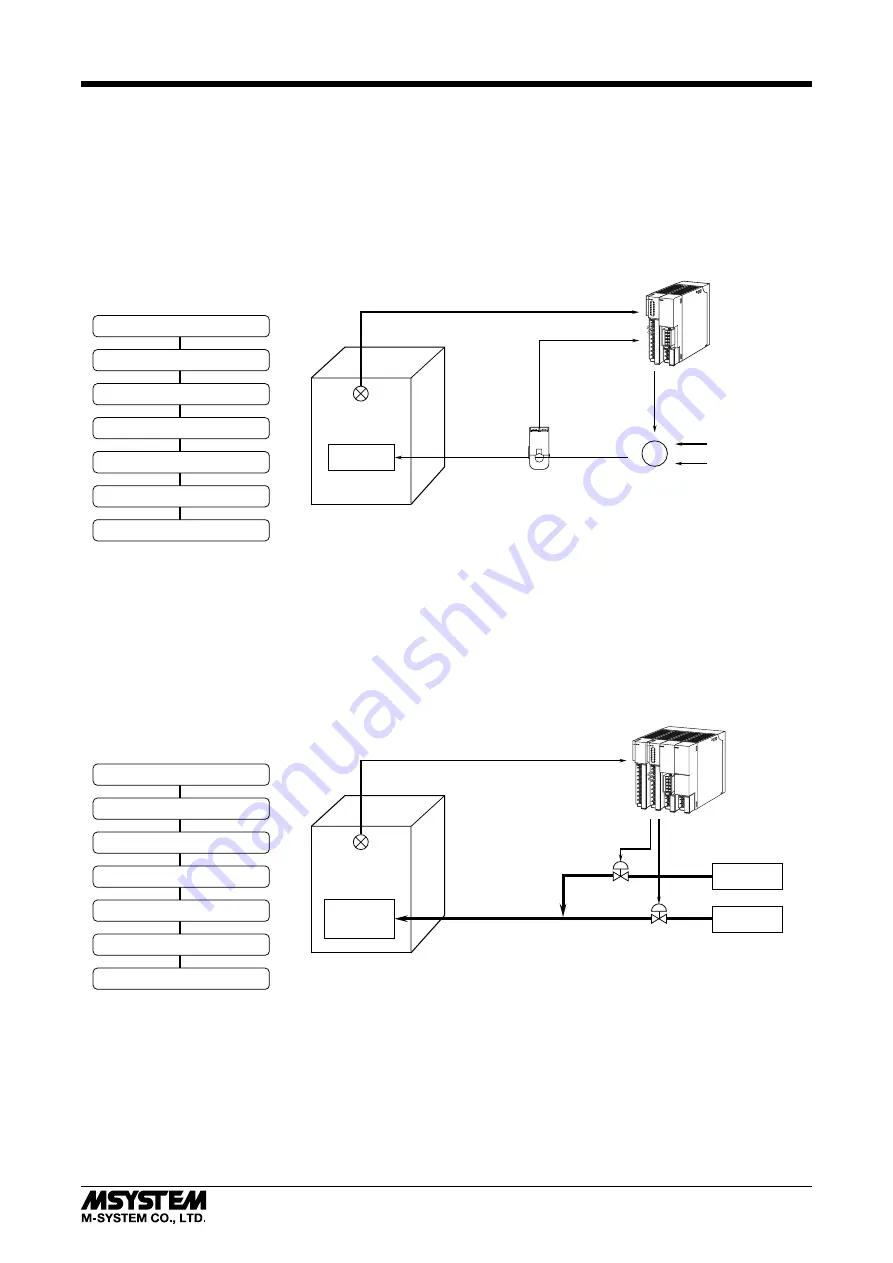

1 loop heating and cooling control (PID)

1. Installation example:

• Base (model: R3–BS)

• Power Supply Module (R3–PS1)

• Interface Module (model: R3–NM3)

• Temperature Control Module (model: R3–TC2)

• DC Voltage Input Module (model: R3–SV4)

(Other R3 modules also available)

• Object to heat/cool

• Temperature sensor

2. Proccess until start operating:

Control output 2 (Mv2)

Control output 1 (Mv1)

UNIVERSAL INPUT 1 (Pv1)

Object to

heat/cool

Cold water

Hot water

Select control mode (PID)

Set deadband

Specify target temperature (SP)

Select operation mode (auto)

Start operation

Temp. Sensor

Turn ON power supply

Set input sensor type and range

Note: The examples above are for single loop, however, dual loop control is also availabe using only one R3-TC2.