R3-TC2

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-8468 Rev.3 P. 14 / 37

■

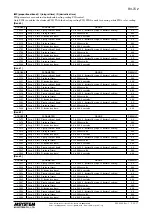

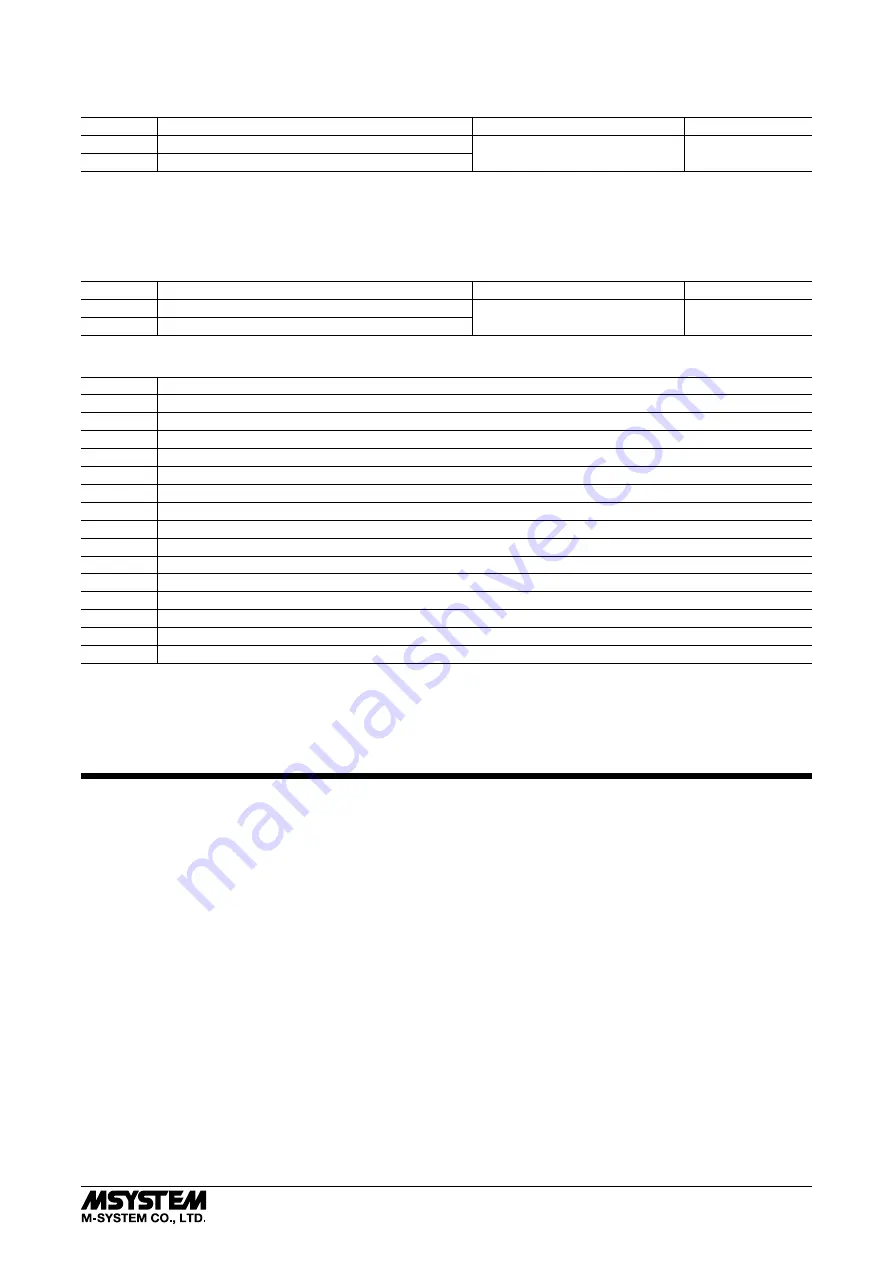

SETPOINT VALUE SETTING

SP for each loop can be changed via Modbus.

ADDRESS

PARAMETER

RANGE

DEFAULT

+6

Loop 1, Local SP (setpoint value)

-3200.0 to +3200.0

(decimal by input 1/2 decimal setting)

---

+14

Loop 2, Local SP (setpoint value)

These registers are overwritten by the SP in bank setting when the power supply is turned off or when the bank is switched.

Write the SP in the bank setting if the values should be maintained.

■

COMMAND EXECUTION

Predefined commands for each loop can be issued via Modbus by writing in the following addresses.

ADDRESS

PARAMETER

RANGE

DEFAULT

+64

Loop 1, Command

See the table below.

---

+65

Loop 2, Command

Available commands are as in the table below:

COMMAND

PARAMETER

1

Set loop operation to RUN

2

Set loop operation to STOP

3

Set control mode to AUTO

4

Set control mode to MANUAL

8

Reset all latched alarms in the loop

9

Reset all latched PV alarms

10

Reset all latched CT alarms

16

Switch to Bank 0

17

Switch to Bank 1

18

Switch to Bank 2

19

Switch to Bank 3

24

Run auto-tuning in the conditions specified by Bank 0

25

Run auto-tuning in the conditions specified by Bank 1

26

Run auto-tuning in the conditions specified by Bank 2

27

Run auto-tuning in the conditions specified by Bank 3

Loop operation, control mode and bank switching operation can be executed by an event input, however, using both commands

and event inputs may cause an unexpected result. We recommend that a function assigned to an event input be not controlled

by a command.

SETTING

■

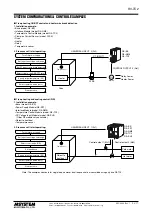

SETTING CHANGE VIA MODBUS

Reading and writing via Modbus from the host is possible by the Network Module (model: R3-NM3).

Parameters are listed with Modbus address and data size in this manual. Access Holding Registers at these addresses to read

and write to refer and change settings.

Refer to “COMMUNICATION” section for the procedure.