Maintenance

Lubricating and Greasing Instructions

The engine should be well oiled and greased in order to run properly.

Regularly lubricate all axles and pickup rollers to prevent squeaking. Use

light household oil, such as that found in M.T.H.'s maintenance kit. Do

not over oil. Use only a drop on each pivot point.

The locomotive’s internal gearing was greased at the factory and should not need

additional grease until after 50 hours of operation or one year, whichever comes first.

Follow the greasing instructions below. Note that in some tightly packed engines you

may need to move internal components temporarily in order to access the gears.

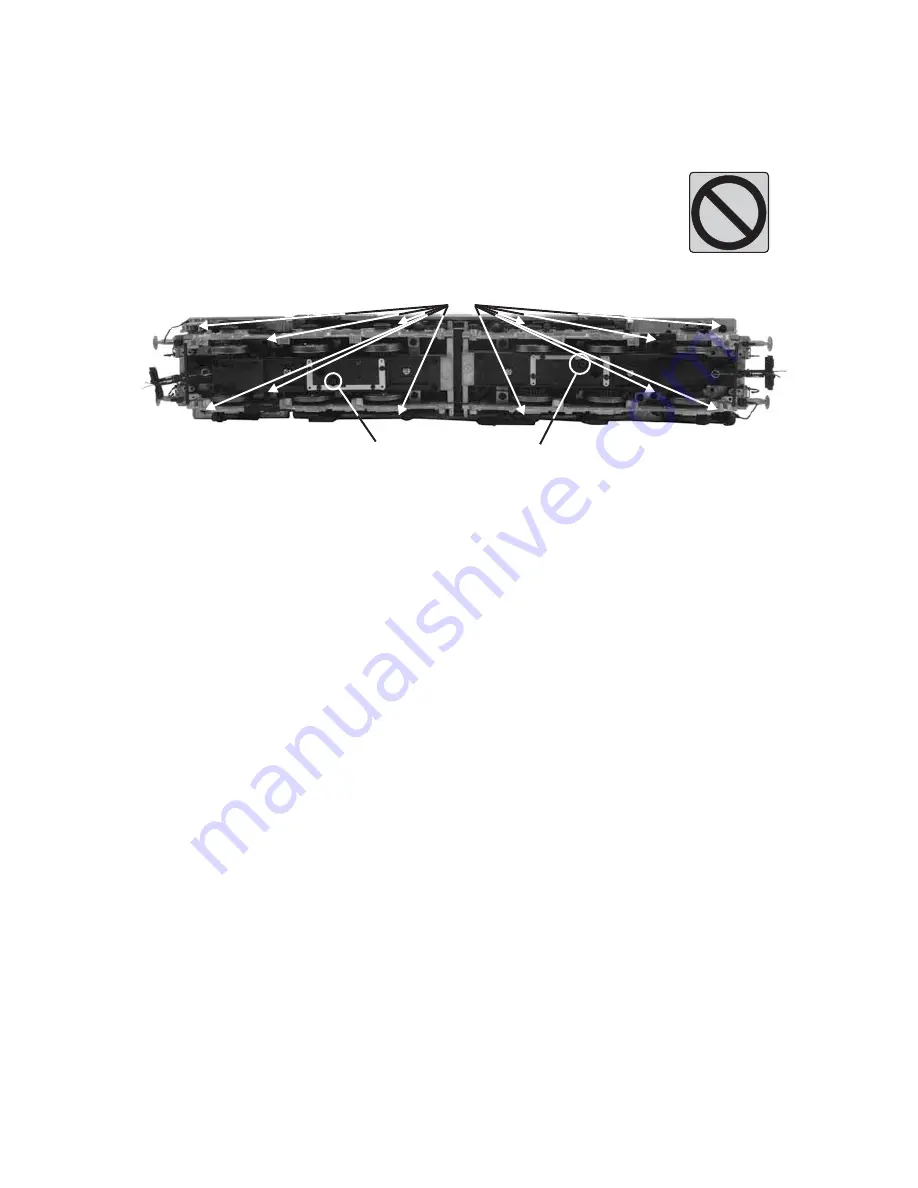

1. To access the motor/gear box, remove the cab from the chassis by unscrewing the

body mount screws as seen in Figure 9 and lifting the cab from the chassis.

2. Once the cab is removed, remove the trucks by unscrewing the black Phillips motor

mount screw located on the underside of the drive trucks.

3. Once the motor mount screw has been removed, pull the motor away from the truck

block and lightly coat the motor worm gear and bronze drive gear (in the truck block)

with grease. Rotating the flywheel by hand will help separate the motor from the

gearbox.

4. Reassemble the truck and motor, being careful not to pinch any wires between the

truck block and motor mount. Rotating the flywheel in the opposite direction of the

removal will help properly seat the motor in the gearbox and make it easier to re-

insert the motor mount screw.

5. After repeating the procedure for the other motor, reassemble the chassis and body,

being careful that the wire harnesses are not caught between the chassis and body,

and reinstall the body mount screws.

Figure 11: Body Removal Screw Locations and Motor Mounting Screws

DO NOT

OVER OIL

DO NOT

OVER OIL

Premier E94 Crocodile Electric Engine

42

Motor Mounting Screw

Body Mount Screws