Traction Tire Replacement Instructions

Your locomotive is equipped with two neoprene rubber traction tires on each

powered truck block. While these tires are extremely durable, you may need to

replace them at some point.

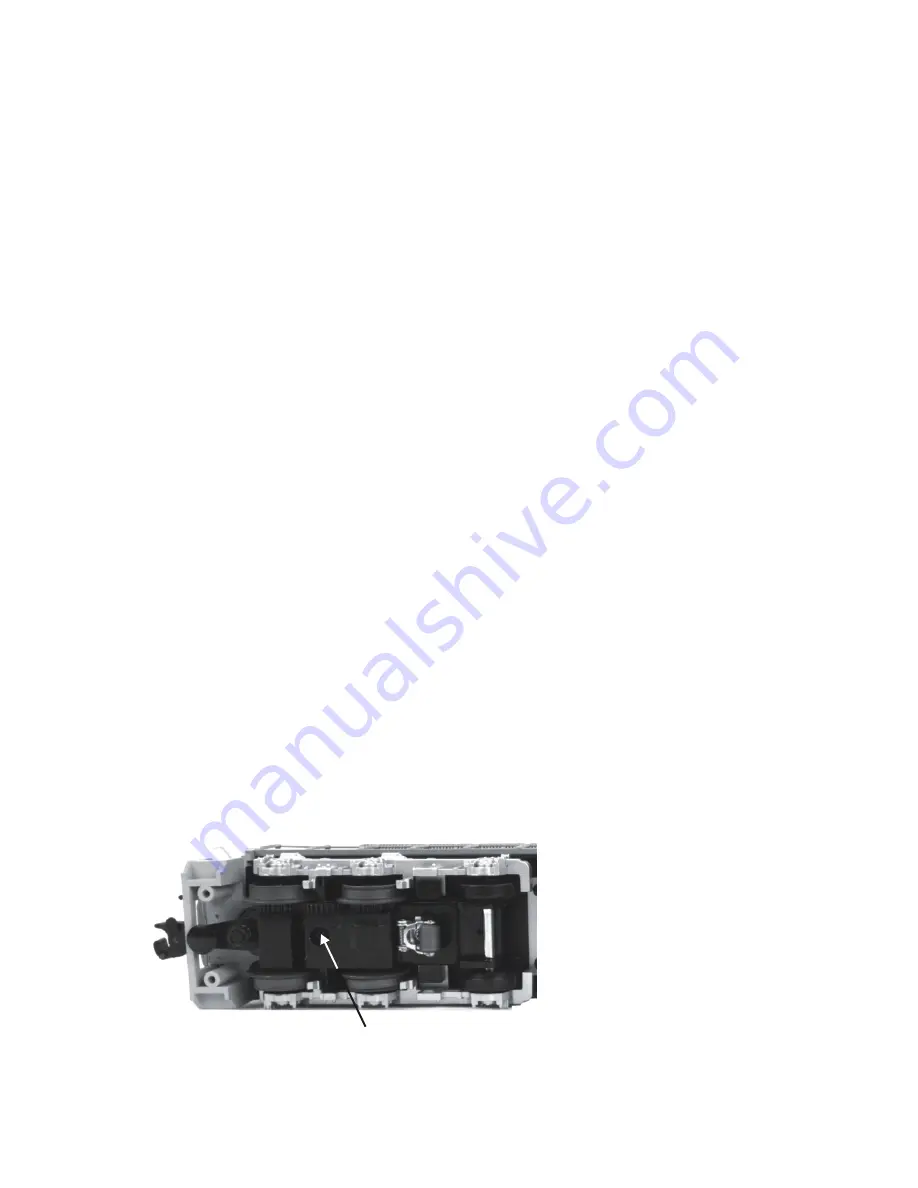

First, remove the truck sides from the truck block. To do this, turn your engine

upside down. If there are visible Phillips screw heads between the truck frame and

truck block (see below), go to step A. If not, go to step B.

A. Remove the two Phillips screws that attach each truck side to the truck block.

B. Remove the trucks from the chassis as described in lubricating and greasing

instructions. Remove the truck sides from the trucks in order to slip the new tire

over the grooved drive wheel. Once the truck sides have been removed:

1. Make sure the old tire has been completely removed from the groove in the drive

wheel, using a razor blade or small flathead screwdriver to pry away any remains.

2. Slip the new tire onto the wheel. You may find it useful to use two small

flathead screwdrivers to stretch the tire over the wheel.

3. If you twist the tire while stretching it over the wheel, you will need to remove

and reinstall the tire. Otherwise your engine will wobble while operating.

4. Make sure the tire is fully seated inside the groove. Use a razor blade to trim

away any excess tire that doesn’t seat itself inside the groove properly.

5. Reassemble in reverse order.

One set of replacement tires is packaged with the model. Additional tires are

available directly from the M.T.H. Parts Department (Order online: www.mth-

railking.com, e-mail: parts@mth-railking.com,Fax: 410-423-0009, Phone: 410-381-

2500, Mail: 7020 Columbia Gateway Drive, Columbia MD 21046-1532, ).

Motor Mount Screw

RKS SD70ACE with Horn & Bell

8

Truck Side Mounting Screws

are on top of truck block

follow step B above