11

To select the mode, rotate the hammer/screw/

drill mode selection ring until the icons Or

align with the indicator and clicks into position.

16. BIT STORAGE

When not is use, the bit provided with the drill can

be stored on the base of the drill by snapping it

into place in the bit clip.

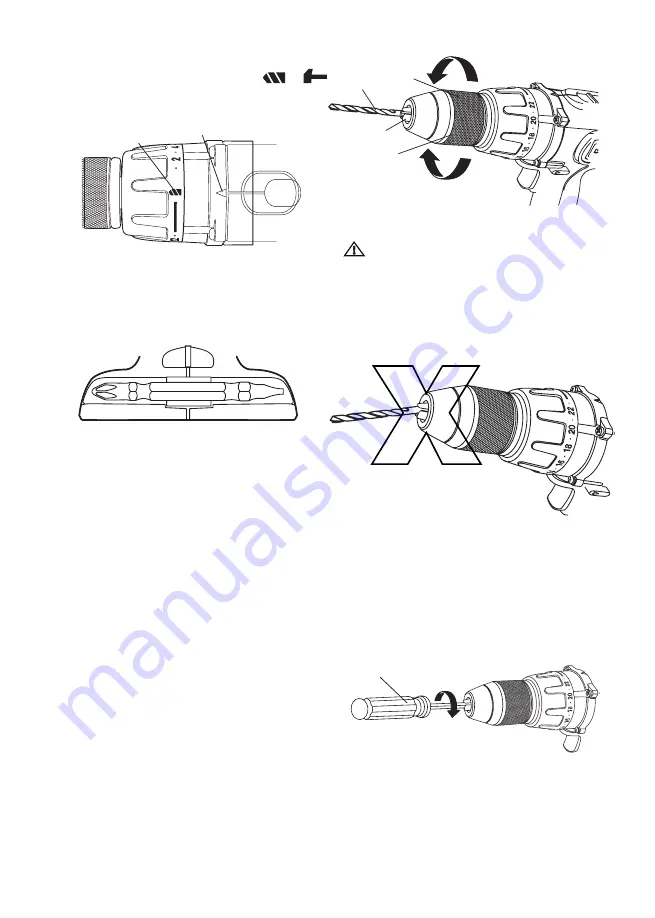

17. INSTALLING BITS

1) Lock the trigger switch by placing the direction

of rotation selector in the OFF (center) position.

2) Open or close the chuck jaws to a point where

the opening is slightly larger than the bit size

you intend to use. Also, raise the front of the

drill slightly to keep the bit from falling out of the

chuck jaws.

3)) Insert a drill bit.

4) Tighten the chuck jaws securely on the bit.

NOTE:

Rotate the chuck body in the direction of

the arrow marked GRIP to close the chuck jaws.

Do not use a wrench to tighten or loosen the

chuck jaws.

18. REMOVING BITS

1)) Lock the trigger switch by placing the direction

of rotation selector in the OFF (center) position.

2)) Open the chuck jaws.

NOTE:

Rotate the chuck body in the direction

reverse to the arrow marked GRIP to open the

chuck jaws. Do not use a wrench to tighten or

loosen the chuck jaws.

3)) Remove the drill bit.

WARNING:

Make sure to insert the drill bit

straight into the chuck jaws. Do not insert the

drill bit into the chuck jaws at an angle then

tighten, as shown in the figure.

This could cause the drill bit to be thrown from

the drill, resulting in possible serious personal

injury or damage to the chuck.

19. CHUCK REMOVAL

The chuck can be removed and replaced by a

new one.

1) Lock the trigger switch by placing the

direction of rotation selector in center position.

2) Open the chuck jaws.

3) Using a screwdriver to turn the chuck

clockwise to remove the chuck screw.

4) Insert a 5-16-in. or larger hex key into the

chuck of the drill and tighten the chuck jaws

securely.

5) Tap the hex key sharply with a mallet in a

clockwise direction. This will loosen the screw

in the chuck for easy removal.

Drill icon

Torque indicator

OPEN

(release)

GRIP

(tighten)

Ratcheting

keyless

chuck

Chuck

body

Chuck

jaws

Drill bit

Screwdriver

Summary of Contents for DD1813

Page 17: ...17...

Page 18: ...18 1 2 Chuck Cordless Drill ltem No DD18132A...

Page 20: ...20 1 2 Chuck Cordless Hammer Drill ltem No DH18262A...

Page 39: ...17...

Page 40: ...18 1 2 Chuck Cordless Drill ltem No DD1813...

Page 42: ...20 1 2 Chuck Cordless Hammer Drill ltem No DH1826...