2

1. This tool should only be used as a

hand operated tool. It is powered by compressed air and is not

insulated against electric shock.

2. This tool is specially designed for riveting sheet metals together. Any

application or use of this tool other

than what it is designed for is strictly prohibited.

3. High sound levels may cause hearing damage. Always wear hearing protection when operating this tool.

4. Wearing eye/face protection can reduce the danger of high-speed materials being ejected from tool use.

5. User must wear proper clothing. Loose clothing, long hair, stings, straps, belts and jewelry should not be

worn when operating this tool.

used are compatible with this tool.

7. Check the protection against the ejecting of rivet stem in place and is operative.

this tool.

9. Always turn o ff t he a ir s upply and d isconnect t he a ir hose before changing r ivet n ose or m aking

adjustments on this tool.

r

o

g

n

it

c

e

n

n

o

c

n

e

h

w

r

o

yl

p

p

u

s

y

g

r

e

n

e

f

o

e

r

u

li

a

f

a

si

e

r

e

h

t

fi

r

e

g

n

a

d

d

i

o

v

a

o

t

r

e

v

e

l

e

lt

t

o

r

h

t

e

h

t

e

s

a

e

l

e

R

.

0

1

disconnecting the air hose.

11.Prolonged use will cause user fatigue. Periodic breaks are recommended for user safety.

12.It is recommended to stop operating the tool whenever the user experiences discomfort, tingling or pain

during use.

13.Beware i f the compressed air hose breaks unexpectedl y, o r is being c onnected or d isconnecte d

improperly. This whipping action may cause injury.

Warning:

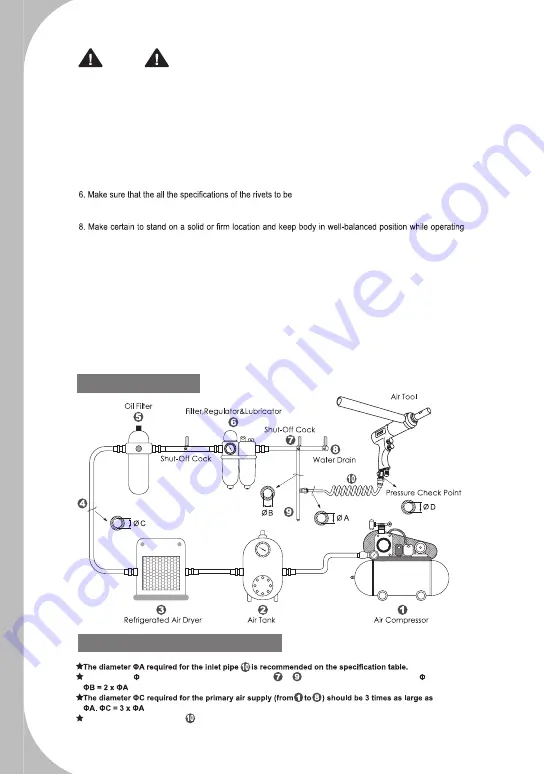

Ideal system connection:

Piping diameters and length requirement:

.

A

s

a

e

g

r

a

l

s

a

s

e

m

it

2

e

b

d

l

u

o

h

s

)

o

t

m

o

r

f(

e

p

i

p

h

c

n

a

r

b

e

h

t

r

o

f

d

e

ri

u

q

e

r

B

r

e

t

e

m

a

i

d

e

h

T

The length for the inlet pipe should be less than

feet ( . m).

Summary of Contents for PC-1012

Page 9: ...9 M 8 M 1 2 Put in the front the Collet Install the tapping bit...

Page 11: ...11 M 3 M 4 M 1 2 M 3...

Page 12: ...12 AIR TAPPING TOOL ltem No PC 1012...

Page 14: ...14...