- 28 -

Condenser fan

The condenser fan is located on the back of the unit.

Gives FORCED-DRAFT cooling for the condenser

coil.

1. Remove the 1/4 "screws (5) from the rear access

panel and remove the rear panel.

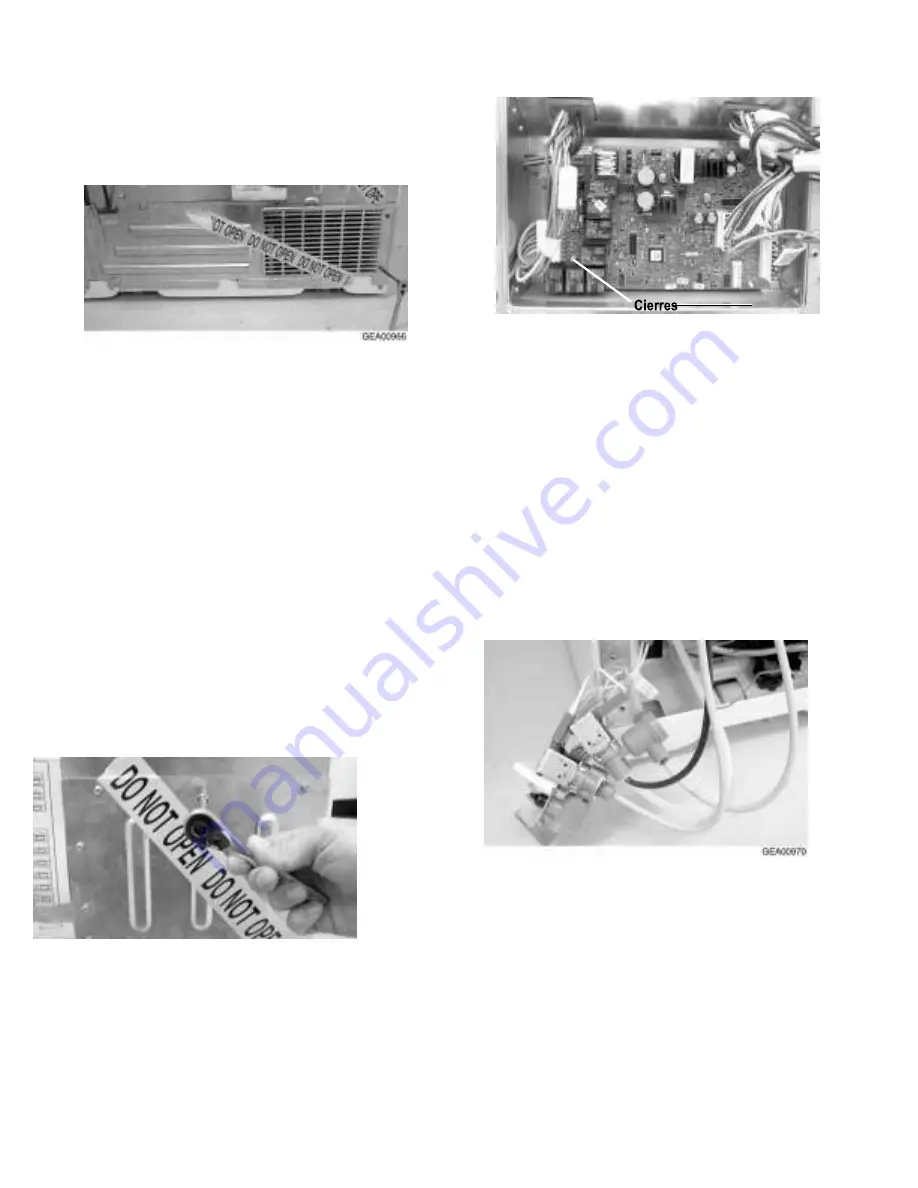

Water selenoids

GEA0096

When the selenoids receive a signal from the

processor, they send water to the filter, cooler and ice

machine.

1. Remove the 1/4 "screws (10) from the rear panel

and remove it.

2. Remove the 1/4 "screw from the clamp.

3. Slide the solenoid assembly outward.

4. Disconnect the cable assembly.

5. Disconnect the water pipe. To disconnect the quick

connection, push the black lip in and pull the tube out.

6. Remove the solenoid

2. Remove the 1/4 "mounting screw from the

condenser fan and slide the fan until the wire is

exposed.

3. Disconnect the supply wire connector.

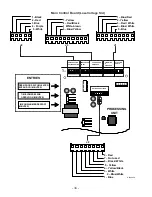

Main Processor Card

The main processor card is located on the back of

the unit. This card controls the operation of the unit.

If a cut on a fan has occurred, replace the fan

before the card and the card will be destroyed.

1. Secure the power to the unit.

2. Remove the 1/4 "screws (10) from the

processing board panel and remove the panel.

3. Disconnect the processor connector cables.

4. Remove the card by opening the plastic lugs

located at the corners of the card.

Summary of Contents for PSS21 Series

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ...The Condenser Fan Does Not Work ...

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 55: ... 53 Shock absorber Cooler thermistor Cooler lights Cooler light switch GEA00980 ...

Page 56: ... 54 GEA00977 Condenser fan Jelly Roll ...

Page 61: ......