13

OPERATION INSTRUCTION

1. Open the power switch, screen will show set current volume and ventilator is beginning to revolve.

2. Adjust knobs of welding current and arc-striking push, make welding function complies with

demands.

3. Generally, welding current is adequate to welding electrode according with as following.

Specification

(

mm

)

Φ1.6

Φ2.0

φ2.5

φ3.2

φ4.0

φ5.0

Φ6.0

Current

(

A

)

25~40A

40~65A

50-90A

90-130A

140-210A 190-270A 260~300A

4. Knob of arc-striking drive is use to adjust welding function, specially in low current arrange, that is

cooperated with knob of welding current adjustment, they may adjust current of arc striking and be

out of control of knob of welding current adjustment .So machine can grain powerful energy and

push current can achieve effect that may .

5. If the anti-shock device is installed in the machine. When the switch of back panel is put "ON"

position, the VRD indictor is lit, and when the switch is put "OFF" position, the VRD indicator is off,

then the no-load voltage is 60-70V. Switch of VRD is put inside the machine, with the "on" condition.

the no-load voltage changes to be less than 15V, which is safe for people.

6. If welding machine has been coordinated remote control device:

1)

Make sure the switch position of remote control device before operation .If switch is on “OFF”

Position that is out of remote co

ntrol. Switch is on “ON” position that is using remote control

device.

2) Insert plug of remote control in socket of remote control correctly and tighten firmly in order to

prevent poor contact.

3) If remote control device is not be used, make sure the switch is

on “OFF” position, or welding

current will not be adjusted on panel.

7. Hot initiation: Heavy current, perfect effect, striking easier.

WARNING!

Before connecting operation please make sure all the power is turned off. The right

order is to connect the welding cable and ground cable to the machine first, and make

sure they are firmly connected and then put the power plug to the power source.

Summary of Contents for ARC 400IT

Page 1: ...ARC 400IT WELDING MACHINE USER MANUAL...

Page 12: ...12 Installation Diagram Power Supply Workpiece Earth Clamp Electrode Holder...

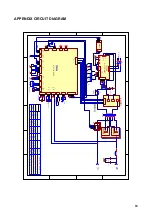

Page 20: ......

Page 21: ......