4

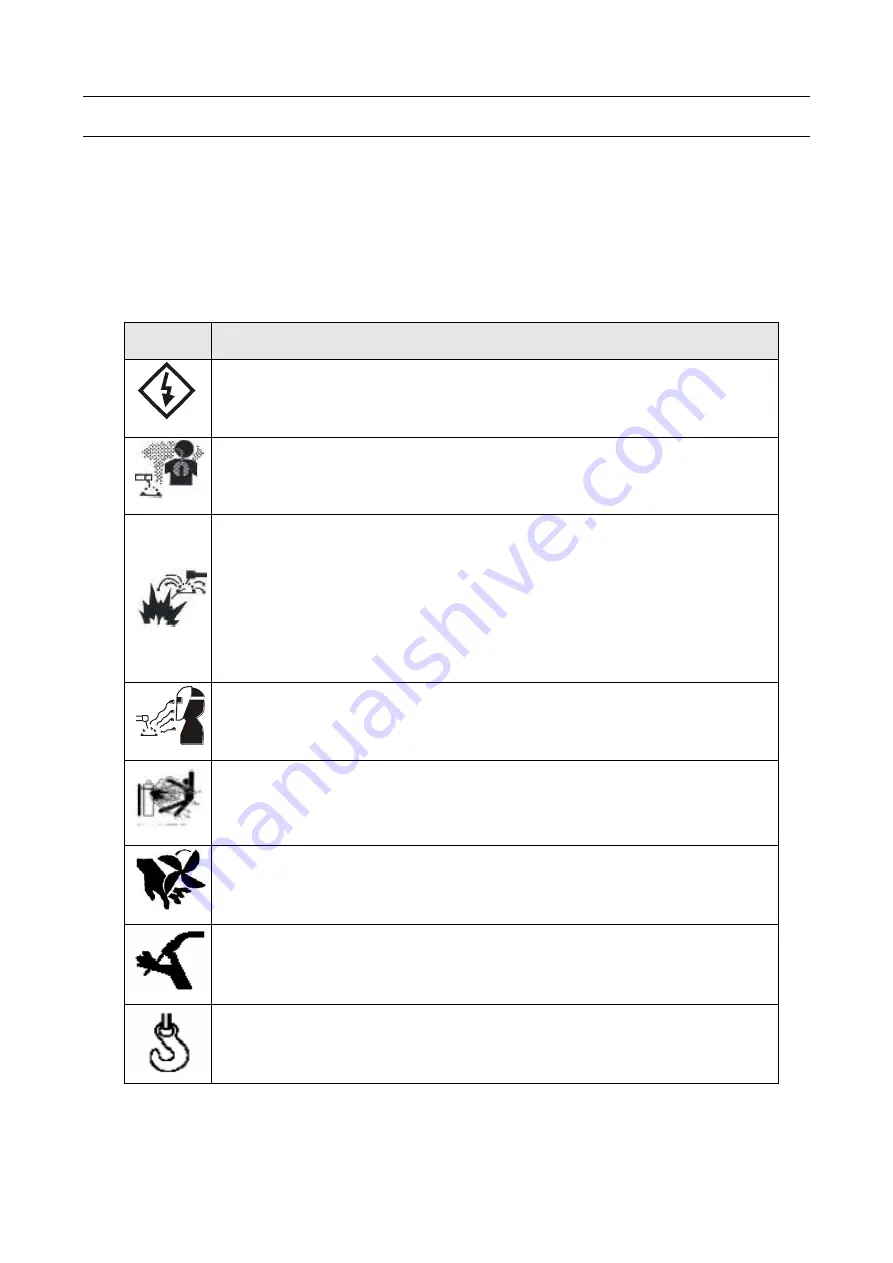

SAFETY WARNING

The safety notes listed in this manual is to ensure correct use of the machine and to keep you and other

people from being hurt.

The design and manufacture of welding machine considers safety. Please refer to the safety warning

listed in the manual to avoid accidents.

Different damage would be caused by wrong operation of the equipment as follows. Please read the

user manual carefully to reduce such damage.

Sign

Description

Any contact of electric parts may cause fatal electric shock or burnt.

Gas and fumes are harmful to health.

Operation in narrow space may cause choke .

Spark and hot workpiece after welding may cause fire.

Bad connected cable may cause fire.

Incompletion connection of workpiece side circuit may cause fire.

Never weld on the case of tinder stuff, or it may cause explode.

Never weld airtight containers such as slot, pipe etc., or it may break.

Arc ray may cause eye inflammation or skin burnt.

Spark and residue will burn your eyes and skin.

Toppling over of the gas cylinder will cause body hurt.

Wrong use of the gas cylinder will lead to high-pressure gas eruption

and cause human hurt.

Never let fingers, hair, clothes or etc. near the moving parts such as

the fan.

The wire shoot out of the torch may stab eyes, face and other naked

parts.

Never stand in front of the swang equipment or under it, or it may fail

and cause injury.

Summary of Contents for ARC 400IT

Page 1: ...ARC 400IT WELDING MACHINE USER MANUAL...

Page 12: ...12 Installation Diagram Power Supply Workpiece Earth Clamp Electrode Holder...

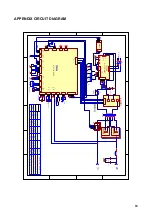

Page 20: ......

Page 21: ......