3

Having unpacked your machine and its accessories, please check the contents against the

equipment list “What’s in the box”, if there are any discrepancies, please contact us using the

procedures laid down in the catalogue. Please dispose of the packaging responsibility, much

of the material is bio-degradable. The machine and its accessories will arrive coated with

heavy corrosion preventative grease. This will need to be cleaned from the machine, its

components and accessories prior to its being set up and commissioned. Use coal oil, paraffin

or a proprietary degreaser to remove the barrier grease. Be warned, it will stain if you splash it

on clothing etc., wear overalls et al., rubber gloves are also a good idea, as is eye protection if

your cleaning process tends to be a little bit enthusiastic. After cleaning, lightly coat the

machine with a thin layer of light machine oil. N.B if you used paraffin / kerosene make sure

you apply this thin film sooner rather than lather

Please read the instruction Manual prior to using your new machine; as well as the installation

procedure, there are daily and periodic maintenance recommendations to help you keep your

machine on top line and prolong its life. Keep this instruction Manual readily accessible for

any other who may also be required to use the machine.

The BV20 required to be mounted on a rigid bed, this is to ensure stability of the machine and

to attenuate any vibration that is generated when the machine is running, (especially with

eccentric work mounted in the chuck).

The bed should be flat and set level in both planes, and at a height that enables comfortable

operation of the machine. It is not necessary to anchor the bed through to the floor, but it must

be stable enough to remain immovable during any normal forceful operations (especially

tightening) carried out whilst operating your lathe.

If you are preparing your own bed for the machine, it should be at least 870mm long by

320mm wide, you will need to drill two 14mm holes to allow for bolt fixing. Set out the centers

of the holes as follows

sizes are minimum excepting distance between centers).

From the left side of the bed (Headstock side) 170mm,150mm from the front edge of the bed.

Distance between centers 650mm; second hole again 150mmfrom front edge.

Bolt the lathe to the bed using M12 nuts, bolts and washers.

Once the lathe is mounted, remove the headstock cover plate and fill the headstock with

SAE20 oil to a level slightly above the sight glass. Do not overfill. The gearbox does not have

oil sealed bearing fitted throughout, and if you overfill oil will leak out.

The machine was fully greased and oiled before leaving the factory, but it would certainly be

prudent for you to check and re-oil all the lubrication points and lube all the beds / slides etc.,

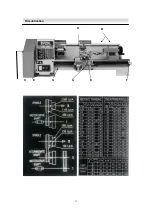

before start up. Refer to the lubrication chart later in this manual.

Check the tension of the drive belt. If the belt is too slack, tighten by adjusting the motor

mounting plate, ensuring that you maintain co-linearity of the two pulleys.

Although the machine has been thoroughly tested at the factory, it is recommended that you

carry out a “running in” procedure to check for correct gear meshing, vibration, etc., ensure

the lathe is running “forward” (i.e. the spindle is turning towards you). Select the lowest

spindle speed i.e. 120rpm, and run for approximately 20minutes, check for vibration,

excessive noise, etc. After the 20min period, increase the speed one step at a time and run

for approximately 5 minutes in each gear. Stop the machine before changing gear. If

everything appears satisfactory, reduce the speed to one of the lower registers; manually

drive the saddle back towards the tailstock, check the saddle feed engages positively; engage

the saddle feed and drive the saddle toward the headstock, checking for smoothness of

movement, etc. Engage and disengage the saddle several times during its travel and check

that its travel pick up is smooth. If everything appears to be satisfactory, move the saddle to a

position about mid travel, MAKE SURE THE SPINDLE IS STOPPED, switch the machine into

reverse and check the machine functions equally well whilst running in reverse.

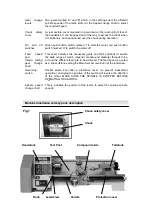

Assembly Instructions

Summary of Contents for BL200L

Page 1: ...N Index of Contents BENCH LATHE BL200L BV20L OPERATION MANUAL ...

Page 10: ...10 ...

Page 14: ...14 ...