5.Safe and installation caution

Read the safe caution before installation and operation .It come down to the high voltage

electricity,electric Arc and high temperature splash.So keep the safe regulation ,operate the machine

properly,avoid the danger of electricity and high temperature arc.

★

Check if any damage ot out looking ot the welder.

★

Confirm the capacity:more than 50A.

★

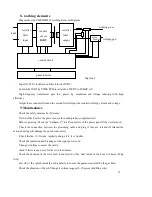

Power source is grounded,diagram 6

★

Prohibit the combustible goods in the welding locale.

★

There is fire proof measure in the welding locale with favorable ventilated condition.

★

There is smoke discharge system if the welding is operated inside the house in order to keep

the safety of workers.

★

The welding operator must be professional workers.

★

The operator must be fitted with safe accessories .Such as safe shoes,gloves,cover,welding

make and welding dress etc.

6. Explanation of installation

6.1 MIG/MAG welding

put the switch "7" MMA/CO

2

/PMIG/DPMIG SWITCH into "PMIG" or "DPMIG" or "CO

2

"

★

Check the products according to the packing list when open the package.

★

Grounded protection.Attached the diagram 6

The power source is 220Vac/(50~60Hz) .The yellow/green double cable is grounding cable.Be

sure to connect the yellow/green double cable into the grounding connection in the welding locale .

Another way is selecting the M8 bolt on the back on the machine and connect the grounding as the

diagram as following.

★

Install the welding gun on the front panel and screw the welding gun ,then lock the bolt.

★

Connect the gas pipe with the gas bottle according to the locale conditions. Check the air proof

conditions to ensure the good airproof.

–

Brown wire

Live

–

Blue wire

Neutral

–

Green/Yellow Wire

Earth (Ground)

8

flow meter

gas

yellow/green double cable

diagram 6

air breaker

back panel.

fan

gasinlet

INPUT

switch for power

power

FUSE

or

fan

NOTICE: