3.3 Function of arc drawing back

★

Reduce the welding criterion at the end of welding line in order to fill the short coming of

welding end.

★

Change the knob on the welding gun ,you may get two kinds of welding criterions to fit for

different position and different thickness.Turn on the switch of :"Arc drawing back".the power now has

the function of Arc drawing back.The voltage adjusting is used by the current knob on the front panel.

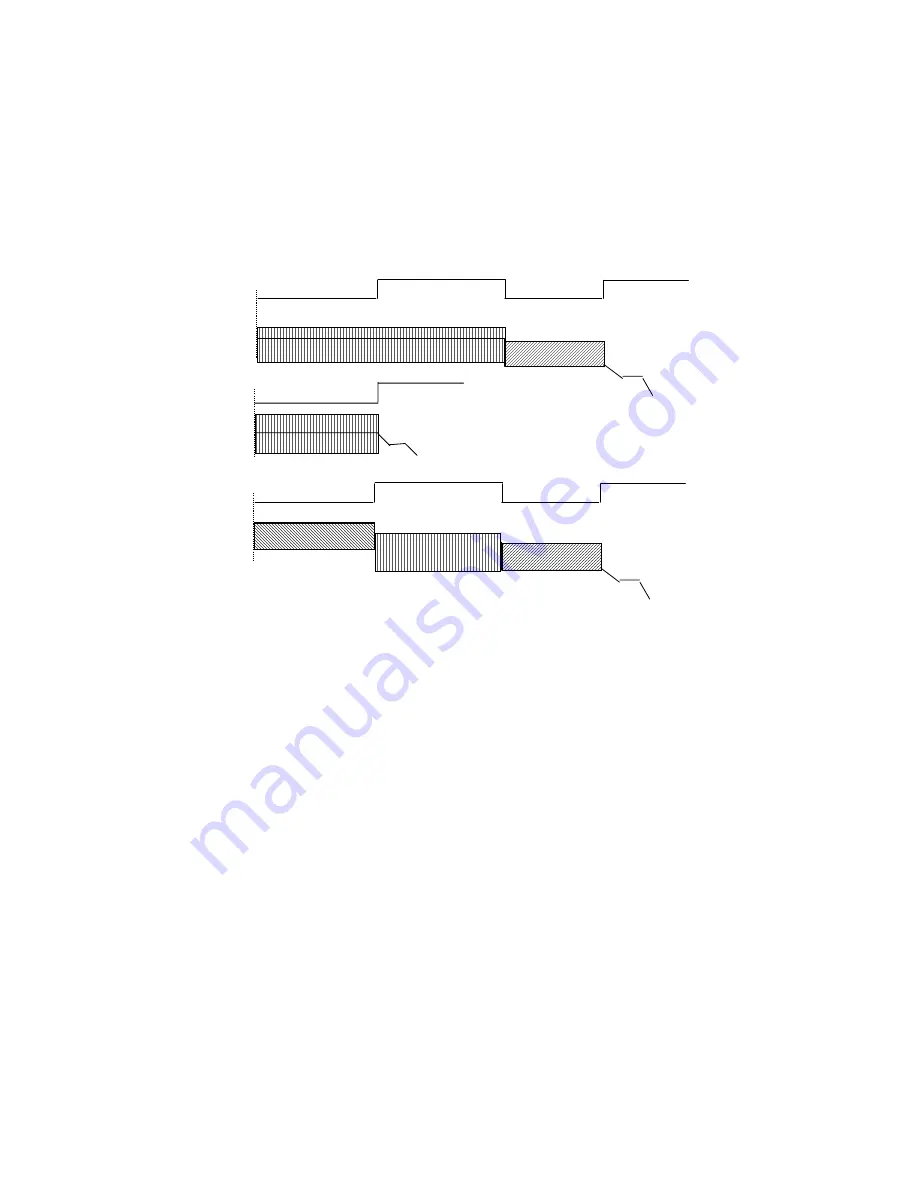

3.4 2/4 steps change(crater mode)

3.5 Function for low Arc starting

We design the function for low arc starting in order to improve the efficiency of arc starting.

3.6 Recycle function

We design the function to settle two problems.

1) Control the diameter of the wire ball at the end of wire .

2) Prevent the wire into the pool after the Arc stop.

3.7 Over current function of the wire feed motor

In order to protect the motor, the wire feed motor may stop rolling automatically if the current

reaches 10A .When it is lower than 10A ,the motor begins rolling automatically.

5

4 steps

2 steps

switch of gun

welding current

ON

OFF

Welding current

end current

current for arc draw back

recycle

recycle

press it one time

(

ON

)

relex it one time

(

OFF

)

press it second time

(

ON

)

relex it second time

(

OFF

)

switch of gun

welding current

welding current

special 4 steps

switch of gun

welding current

End current

current for arc draw back

recycle

press it one time

(

ON

)

relex it one time

(

OFF

)

press it second time

(

ON

)

relex it second time

(

OFF

)

start current

Welding current