Av

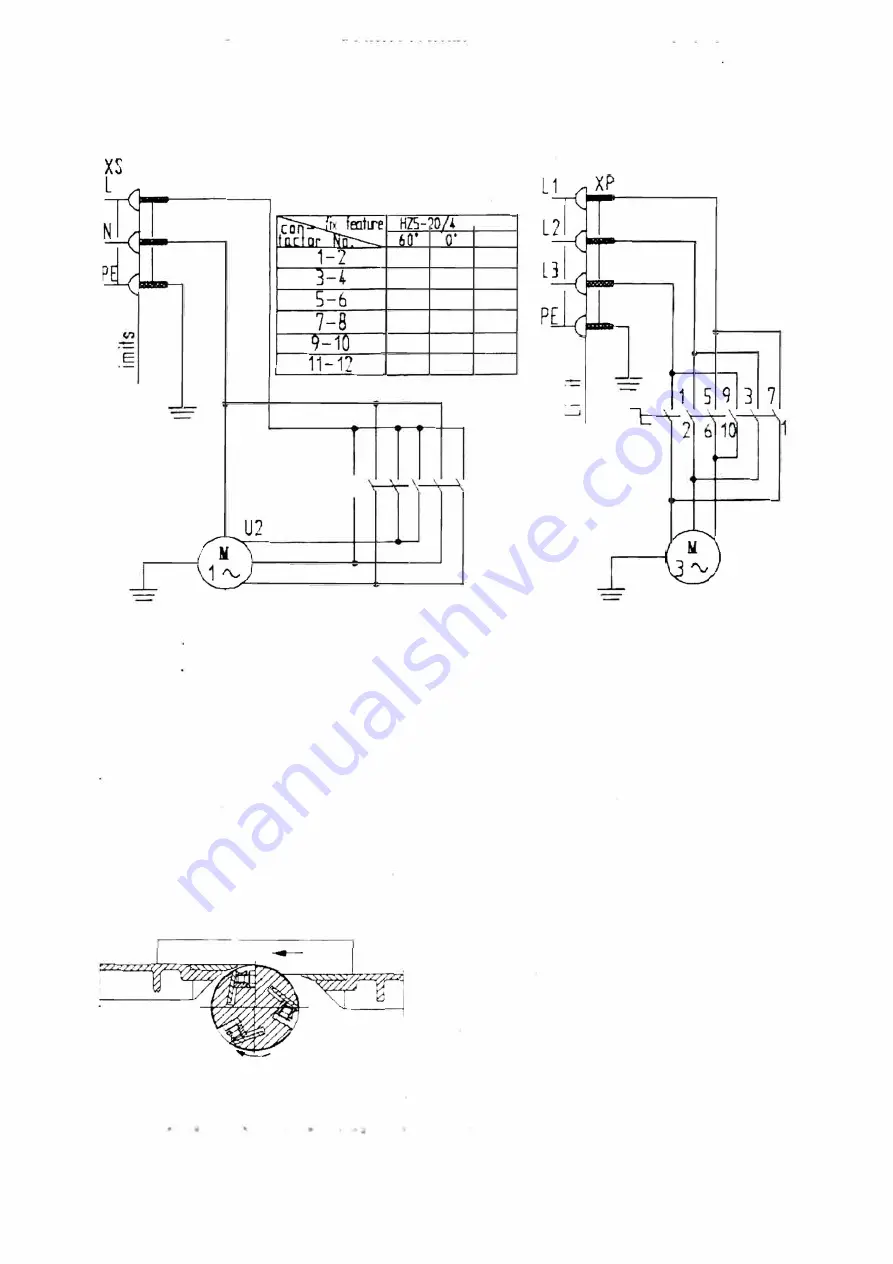

220V .SO Hz

XP

__J

PE

[}ll

QS:

\JI

X

'/

X

Sow

Stop Rare

\!/ \J/

HOS

bo·

X

X

X

x�

"v

380V .SO Hz

PE

V)

E

QS

� 8

2

3 7 11 1 S 9

as

1::-\:-

4 8 12 2 6 10

U1

21

PE

22

PE

Note:

0.

b

1s ma.in winding

U1 U2

Z1 Z2

1s

the sernnd winding

Fig.3 C1rcut: diagram of ekctncai

6 Adjustment and Application

To guarantee security of the operator as well as the machine nself and improve produces quality

and production efficiency, it is imperative for the operator 10 master proficiently the techniques of

adjustment and application of power off .The opera tar must check the validit

y

and reliability of

mstal!ment and adjustment

before

starting

the machine.

• Surface Planer

Preparation: Stop the machine. move the clutch bar

to planning position.

The edges of planer tools must be straight and sharp.

The weight of three planer tools should be

approximately equal. Shift the edges of blades to the

same height as the back plane of the bench or 0.05mm higher than

it.

Adjust height of the front

and back plane referring to the height indicating staff. The height deviation between two planes

m�irns the planer depth Move the lead board

to

the

right side

of the

bench and

fix

it

during

5