38

39

MLMP170H51 by MacAllister

MLMP170H51 by MacAllister

In

more

detail

. . .

In

more

detail

. . .

Spare parts/Replacement parts

The following parts of this product may be replaced by the consumer. Spare parts are

available at an authorised dealer or through our customer service.

Description

Blade

Code: DAYE 263001330

Repair

This product does not contain any parts that can be repaired by the consumer. Contact an

Storage

1. Switch the product off and disconnect the spark plug connector.

2. Clean the product as described above.

3. Store the product and its accessories in a dry, frost-free place.

4. Always store the product in a place that is inaccessible to children. The ideal storage

temperature is between 10 °C and 30 °C.

5. We recommend using the original package for storage or covering the product with

a suitable cloth or enclosure to protect it against dust.

6. Empty the tank if you are not going to use the product for an extended period of time

(more than 30 days) and before storing it for the winter.

Transportation

1. Switch the product off and disconnect the spark plug connector.

2. Adjust the height to the highest position as described above.

3. Attach transportation guards, if applicable.

4. Always transport the product by its handles

(1, 1a).

5. Protect the product from any heavy impact or strong vibrations which may occur

during transportation in vehicles.

6. Secure the product to prevent it from slipping or falling over, loss of fuel, damage

and injury.

Care and maintenance

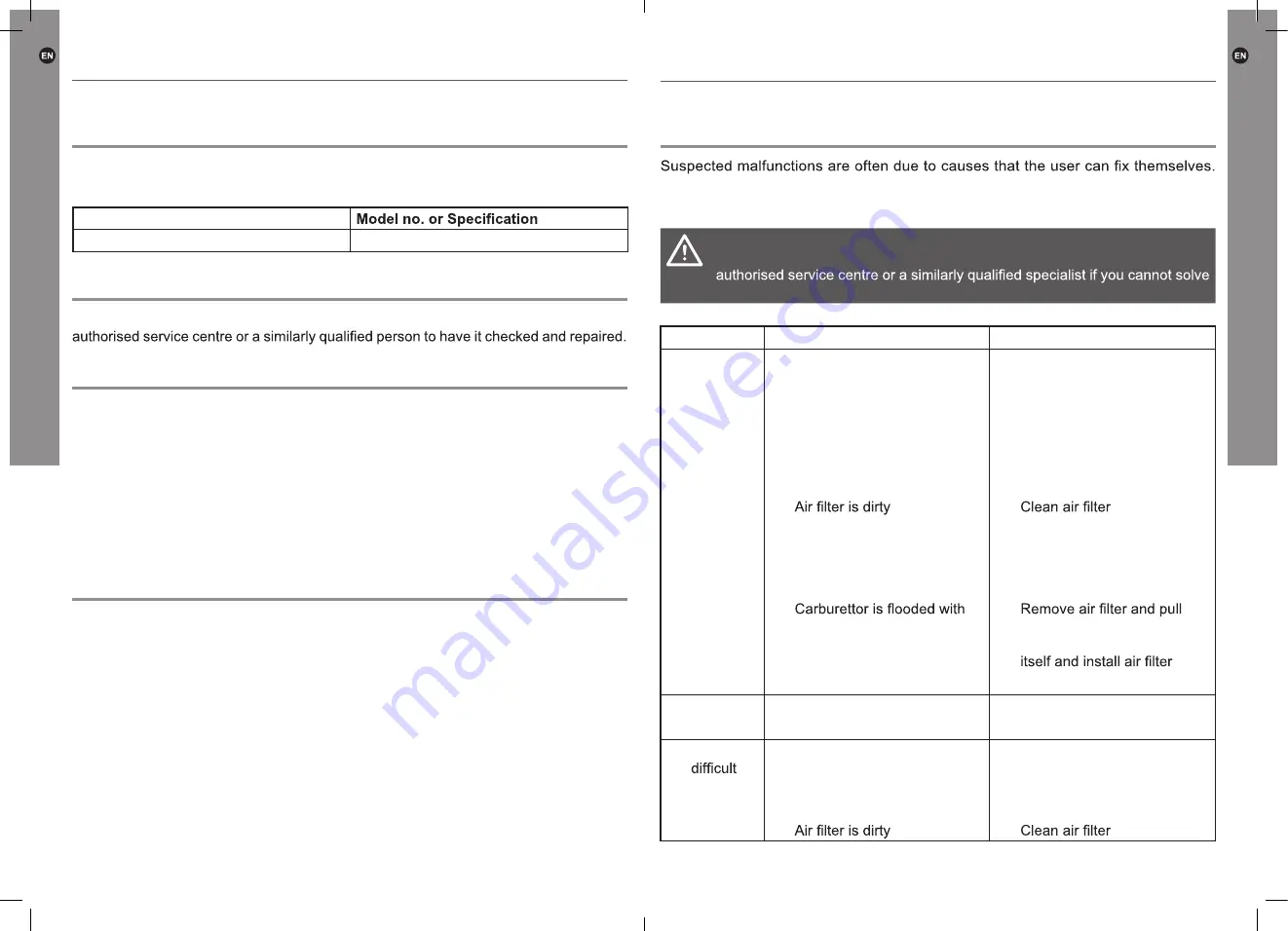

Trouble shooting

Therefore check the product using this section. In most cases the problem can be

solved quickly.

WARNING!

Only perform the steps described within these instructions! All

further inspection, maintenance and repair work must be performed by an

the problem yourself!

Problem

Possible cause

Solution

1. Engine

does not

start

1.1 Not enough fuel in fuel tank

1.1 Add fuel

1.2 Spark plug is wet

1.2 Dry spark plug

1.3 Spark plug is damaged

1.3 Replace spark plug

1.4 Spark plug connector lose

1.4 Attach properly

1.5 Choke control lever not in

the correct position for the

prevailing conditions

1.5 Move choke control lever to

correct position

1.6

1.6

1.7 Spark plug loose

1.7 Tighten spark plug

25-30 N m

1.8 Spark plug gap is incorrect

1.8 Set gap between electrodes

at 0.7-0.8 mm

1.9

fuel

1.9

recoil starter handle continu-

ously until carburettor clears

1.10 Faulty ignition module

1.10 Contact the service agent

2. Engine

stops

2.1 Not enough fuel in fuel tank

2.1 Add fuel

2.2 Cutting device is blocked

2.2 Remove blockage

3. Engine

to start

or loses

power

3.1 Dirt, water or stale fuel in the

tank

3.1 Drain fuel and clean tank. Fill

tank with clean, fresh fuel

3.2 Vent hole in fuel tank cap is

clogged

3.2 Clean or replace fuel tank

cap

3.3

3.3

Trouble shooting