35

MAINTENANCE SECTION

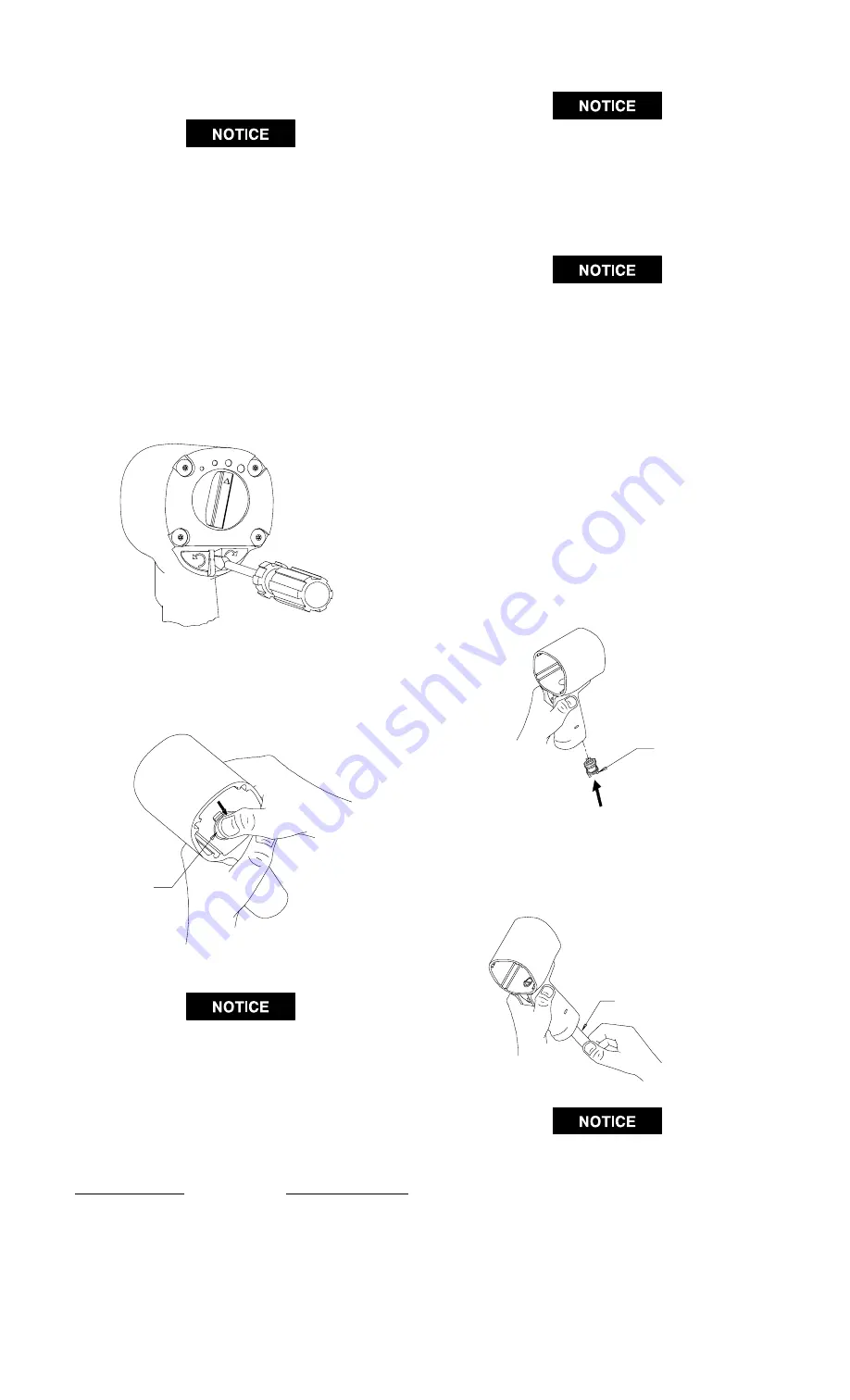

Disassembly of the Reverse Valve Mechanism

The Reverse Valve Assembly cannot be removed

without first removing the Forward and

Reverse Buttons (32) and (33). Therefore, it is

important that the procedure below be followed

exactly.

1.

Notice the notches on either side of the partition.

These notches indicate the correct location for

insertion of a thin–bladed screwdriver used for

removing the Forward and Reverse Buttons. Insert the

screwdriver between the partition and the Button

which is fully extended. Gently pry against the

Button to disengage the detent so that the Button can

be removed. After the Button is removed, reach inside

the Housing and rotate the Reverse Valve to extend

the remaining Button. Repeat

the above procedure

for the remaining Button. See Dwg. TPD1328.

(Dwg. TPD1328)

REMOVAL OF

FORWARD/

REVERSE

BUTTONS

2.

Insert thumb into the front of the Housing and push

down on the Reverse Valve so that it can be removed

through the bottom of the handle. See Dwg.

TPD1329.

REVERSE

VALVE

(Dwg. TPD1329)

Do not try to remove the Reverse Valve by pushing

upward. It can only be removed by pushing it

downward and out of the bottom of the handle. If

the Reverse Valve does not come free, tap the

bottom of the handle lightly with a rubber hammer

until it drops out.

3.

Remove the Top Reverse Valve O–ring (29) and the

Bottom Reverse Valve O–ring (30) from the Reverse

Valve.

ASSEMBLY

General Instructions

1.

Whenever grasping a tool or part in a vise, always use

leather–covered vise jaws to protect the surface of the

part and help prevent distortion. This is particularly

true of threaded members and housings.

Always use leather–covered vise jaws when

clamping the handle in a vise. Leather will

conform to the shape of the handle and allow the

tool to be held securely. To prevent damage to the

exhaust diffuser, never clamp only the bottom of

the handle.

2.

Always clean every part and wipe every part with a

thin film of oil before installation.

Do not remove grease from the impact mechanism

or Hammer Case (15). If the impact mechanism

has not been disassembled, inject Mac Tool

Pneumatic Grease through the Hammer Case

Grease Fitting (17).

When disassembling and assembling the impact

mechanism, remove all grease from the impact

mechanism and Hammer Case and lubricate the

impact mechanism and Hammer Case Bushing (16)

with Mac Tool Pneumatic Grease.

3.

Apply a film of o–ring lubricant to all O–rings before

final assembly.

Assembly of the Reverse Valve Mechanism

1.

Install the Bottom Reverse Valve O–ring (30)

(color–coded blue) and the Top Reverse Valve bring

(29) on the Reverse Valve (28).

2.

Insert the Reverse Valve in the bottom of the handle

making sure that two ears on the Reverse Valve are

facing downward. See Dwg. TPD1330.

EARS

(Dwg. TPD1330)

Use a wooden dowel to push the Reverse Valve up

through the handle until the top of the Reverse

Valve is flush with or slightly above the bottom of

the motor bore in the Housing (19).

See Dwg. TPD1331.

(Dwg. TPD1331)

DOWEL

If the Reverse Valve is pushed up too far and

becomes wedged, it will have to be pushed back

down through the handle and re–inserted from the

bottom of the handle. The Reverse Valve cannot be

removed by pushing it up through the handle and

into the motor bore. If the Reverse Valve must be

removed and re–installed, make sure that the Top

and Bottom Reverse Valve O–rings have not been

rolled off and are in their proper positions on the

Reverse Valve.