JSTT1000 3 6/3/15

SETUP INSTRUCTIONS

OPERATINg INSTRUCTIONS

JSTT1000

1000-LBS.

CAPACITY

TRANSMISSION JACK - 2 STAGE

1. Place the hydraulic power unit in an upright position. Secure the legs (#2-5) to the cylinder (#1-1) with the bolts (#2-3) and washers (#2-4). Do not tighten.

2. Secure swivel casters (#2-1 and #2-2) to leg caster brackets as shown in the exploded view drawing on page 5.

3. Tighten the hardware that secures the legs (#2-5) to the cylinder (#1-1).

4. Place the saddle assembly (RS1000SA) on the stud protruding from the top of the hydraulic unit assembly. Align the hole in the saddle with the hole in

the stud, and secure with the bolt (#3-26) and nut (#3-27).

5. The hydraulic power unit is equipped with two reservoir fill screws (#1-37 and #1-38). The closed filler screw is installed in the reservoir at the factory

so the jack will not leak during shipment.

IMPORTANT: REPLACE THE RESERVOIR FILLER SCREW WITH THE VENTED RESERVOIR SCREW BEFORE USING THE JACK.

6. Sometimes air gets trapped in the hydraulic system during shipping and/or handling. Evidence of an air bound system is when pumping the foot pedal feels

spongy and/or the jack will not pump full incremental strokes.

PURGING AIR FROM THE HYDRAULIC SYSTEM:

a. Depress the release foot pedal while simultaneously pumping the jack about

15 incremental pump strokes.

b. Remove your foot from the release pedal and pump the jack to maximum extension.

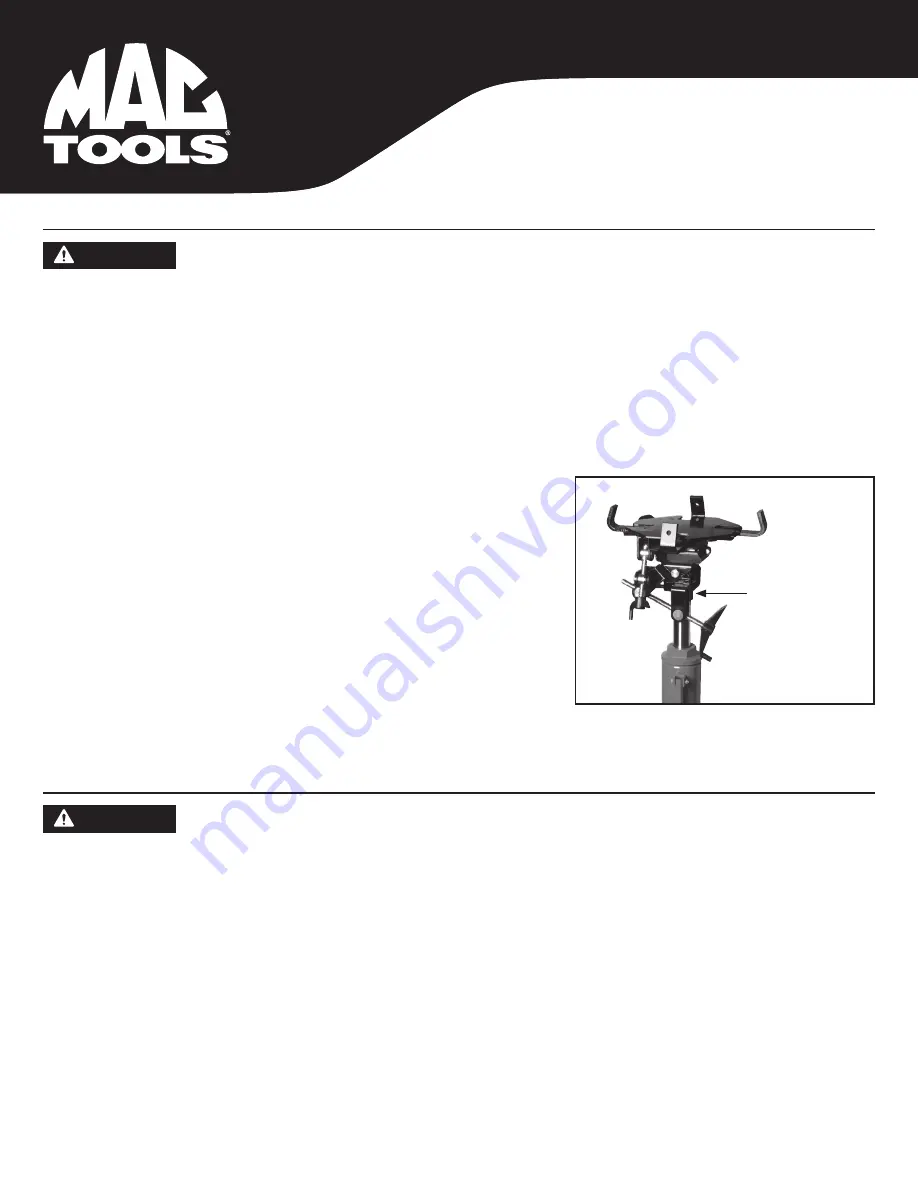

c. If the secondary ram seems to be spongy or does not pump up normally, insert an

Allen wrench in the small Allen socket set screw in the side of the secondary cylinder

nut. (See Figure 1) Slightly turn the set screw in a counterclockwise direction while

lightly depressing the pump pedal. This procedure is similar to bleeding air out of

an automotive brake line. Repeat the procedure until there are no bubbles in the oil

that escapes from behind the Allen socket set screw.

d. Close the Allen socket set screw by turning it in a clockwise direction until tight.

Repeat steps "a" and "b".

e. If the condition seems better, repeat steps "a" through "d" until air is purged from the system.

1. Lift the vehicle to the desired work height and support the vehicle in accordance with the lift manufacturer's recommended support procedure and all the

instructions and warnings in this manual.

2. Use an under hoist stand rated greater than the weight of the engine to support the engine before unbolting the transmission from the engine or bolting the

transmission to the engine.

3. Position the transmission jack directly under the transmission. Depress the large foot pedal up and down in order to raise the saddle to a height very close

to the center of balance point of the transmission oil pan but do not touch the transmission.

4. Adjust the ratchet arms on the saddle so that the bent up section of the arms will fit in the mounting flange around the perimeter of the transmission oil

pan. Slowly and gently pump the jack so the connection is made and then secure the transmission to the jack's saddle with the tie down strap provided.

Sometimes it is necessary to turn the fore and aft and side to side tilt knobs so the saddle is in the proper alignment with the transmission pan before

securing the load to the saddle.

5. Make sure the tie down strap is very tight when securing the transmission to the saddle and before raising or lowering the transmission.

6. Remove the transmission from the engine according to instructions in the vehicle service manual.

7. Once the transmission has been disconnected from the engine, very slowly depress the release pedal to make sure the jack's saddle and transmission do

not hang up on any undercar components, wiring, fuel lines, etc. Continue to lower the jack all the way down.

8. When installing a transmission, follow the above instructions but in the applicable order and according to the vehicle manufacturer's installation procedure.

Location of Allen

socket set screw

in secondary

cylinder nut

Figure 1

Failure to follow these Setup Instructions may result in serious injury or death, and/or property damage.

Failure to follow these Operating Instructions may result in serious injury or death, and/or property damage.

WARNING

WARNING