OM-154 500 Page 15

Parts For Main Assembly

NOTE: All items indented by a dot(s) are included with the item listed directly above.

Description

Part

No.

Item

No.

Part

No.

Item

No.

Description

Part

No.

Item

No.

Description

1

089 899

Latch

2

134 464

Warning Label

3

+151 565

Wrapper

126 838

Drive Assembly

4

124 817

· Drive Housing

5

090 416

· Hinge Pin

6

151 828

· Cotter Hair Pin

7

112 031

· Pressure Lever

8

090 443

· Bearing

111 622

· · Spacer

9

092 237

· Knob

10

090 415

· Spring

11

085 244

· Cupped Washer

12

085 242

· Fastener

13

010 224

· Spring Pin

14

058 549

· Wire Guide

15

126 652

Knob

16

149 332

Hose Clamp

17

134 834

Hose

18

154 828

Drive Roll

19

126 653

Nyl Washer

20

111 912

Insulator

21

147 573

Bracket

22

126 651

Nyl Shldr Washer

23

048 573

Light

24

058 428

Hub

25

057 745

Spring

26

058 628

Brake Washer

27

010 191

Fiber Washer

28

057 971

Keyed Washer

29

057 543

Spring

30

605 941

Washer

31

058 427

Retaining Ring

32

085 980

Nut

33

134 201

Stand-Off Support

34

057 358

Bushing

35

147 569

Baffle

36

108 358

Contactor

37

157 044

Circuit Card

38

*125 847

· Fuse, slo-blo 12A

113 149

Housing, 14 pin

079 747

Terminal

39

072 817

Relay

40

087 156

Varistor

41

155 056

Rectifier

155 054

· Thermostat, NC

026 701

· Insulation

42

152 214

Terminal Assembly

038 618

· Link

43

090 087

Drive Motor

44

112 583

Insulator

45

123 770

Resistor Assembly

117 116

· Resistor

46

162 245

Capacitor

47

022 160

Clamp

48

Base w/Running Gear

152 872

· Base

147 893

· Axle

090 693

· Wheel, 8 in

602 250

· Washer, .750 flat

121 614

· Retaining Ring

109 318

· Caster, 2.500

49

117 014

Fan Motor

50

005 656

Fan Blade

51

147 572

Bracket

52

Rear Panel w/Cmpts

128 751

· Gas Valve

605 227

· Nyl Nut, gas valve

152 118

· Cord Set

111 443

· Bushing, cord set

147 443

· Rear Panel

146 619

· Bezel

147 548

· Speed Nut

156 339

· Bottle Retainer

602 389

· S Hook

156 340

· Chain

602 384

· Snap, chain

53

147 315

Stabilizer

54

147 313

Transformer

146 943

· Coil

55

147 576

Lower Panel

56

Front Panel w/Cmpts

072 623

· Potentiometer

097 922

· Knob

048 482

· Receptacle w/Sockets

079 534

· · Terminal

111 897

· Rotary Switch, 4posn

127 023

· · Knob

116 830

· Rocker Switch, DPST

147 442

· Front Panel

146 619

· Bezel

147 548

· Speed Nut

154 005

· Handle

154 596

· Cap, Handle

153 448

· Nameplate

004 214

· Bushing, 2.000mtg

111 644

· Bushing, .875mtg

57

600 325

Cable

58

026 843

Insulator

59

010 368

Clamp

60

110 720

GA-16C Gun, (Fig 6-2)

153 714

Regulator/Flowmeter

154 829

Hose Kit

112 863

· Adapter Fitting

113 129

· PVC Tubing

089 120

· Hose Clamp, .375–.450

028 509

Regulator Adapter

+When ordering a component originally dis-

playing a precautionary label, the label should

also be ordered.

*Recommended Spare Parts.

Be sure to provide Model and Serial Number

when ordering replacement parts.

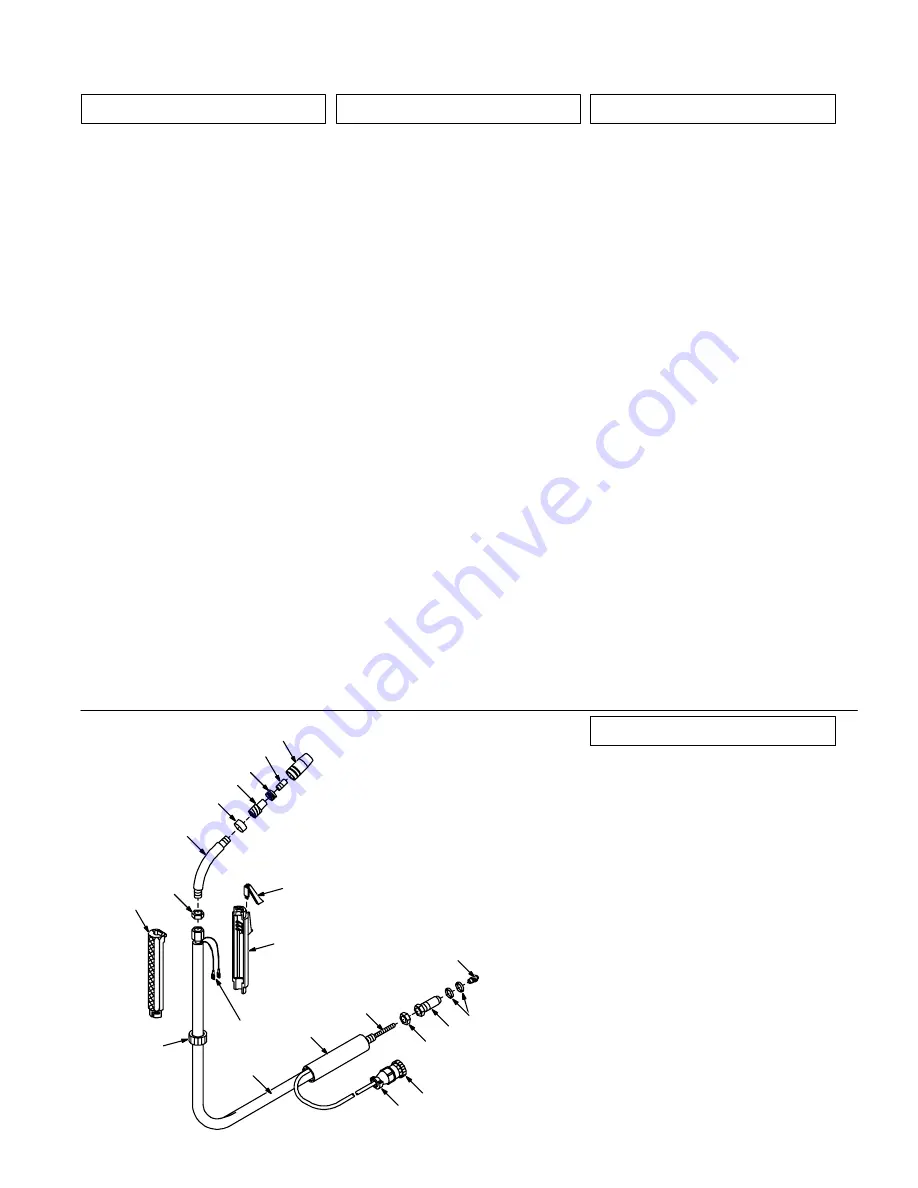

ST-110 832-D

1

110 793

Handle Assembly

110 795

Head Tube

2

110 780

· Nut

3

110 779

· Jacket

4

110 781

· Stop

5

128 878

· Adapter

6

154 819

· Spring

7

154 826

Contact Tube, .023

7

154 825

Contact Tube, .030

7

154 824

Contact Tube, .035

8

154 822

Nozzle, 1/2 orf

8

♦

154 821

Nozzle, 3/8 orf

8

♦

154 820

Nozzle, flat spot

9

110 794

Trigger Switch Assembly

10

080 565

Terminal

11

110 792

Cable

12

110 797

Sleeve

13

167 440

Liner, .023-.035

14

120 715

· Collet, .035

15

079 974

O-Ring, .500

16

110 796

Connector

17

079 878

Housing Plug & Pins

079 535

· Terminal

18

048 834

Clamp

♦

OPTIONAL

Part

No.

Item

No.

Description

1

2

3

4

5

6

7

8

9

1

10

1

11

12

13

14

15

16

17

18

2

Figure 6-2. GA-16C Gun (Fig 6-1 Item 60)

Summary of Contents for MW150K

Page 16: ...OM 154 500 Page 13 Figure 5 2 Wiring Diagram For Welding Power Source SC 163 085...

Page 19: ...Notes...

Page 20: ......